Observation mirror for electric inspection

An electrical inspection and observation mirror technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve problems such as hidden safety hazards, inconvenient adjustment, and increased workload of staff, and achieve careful observation, change light, and reduce difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

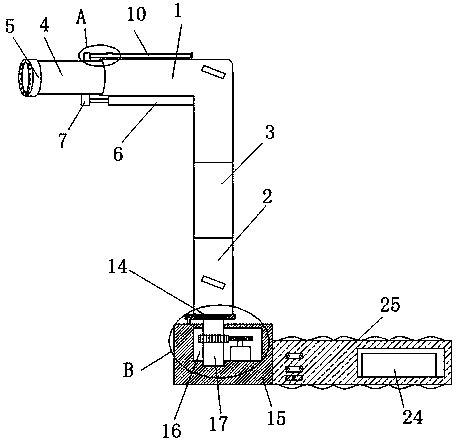

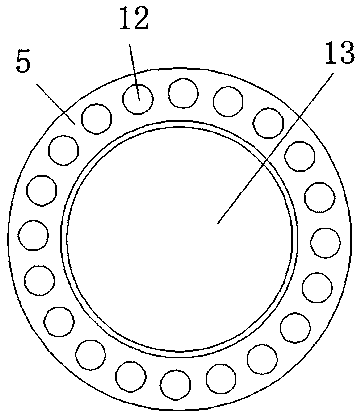

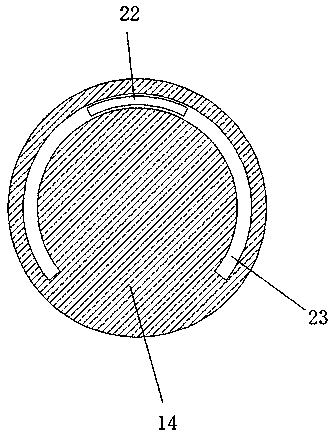

[0026] refer to Figure 1-5 In this embodiment, an observation mirror for electrical inspection is proposed, including a plane mirror, an inspection tube 1 and an observation tube 2, an intermediate tube 3 is arranged between the inspection tube 1 and the observation tube 2, and the inspection tube 1 is arranged in an L-shaped structure , the observation tube 2 is set vertically, an extension tube 4 is movable installed in the viewing tube 1, and one end of the extension tube 4 is screwed with a viewing frame 5, a push rod motor 6 is welded on the bottom of the viewing tube 1, and a push rod motor 6 is welded on the bottom of the extension tube 4. The rectangular block 7, the output shaft of the push rod motor 6 is welded to one side of the rectangular block 7, the top of the viewing tube 1 is welded with a limiting block 9, and a limiting hole 11 is opened on the limiting block 9, and the sliding installation in the limiting hole 11 is limited. Position rod 10, push block 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com