design method for vibration damping of a TBM cutter head

A design method and technology of cutter head, applied in the direction of design optimization/simulation, calculation, mining equipment, etc., can solve the problem of strong cutter head and vibration, and achieve the effect of reducing damage, reducing cost, and enriching vibration reduction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

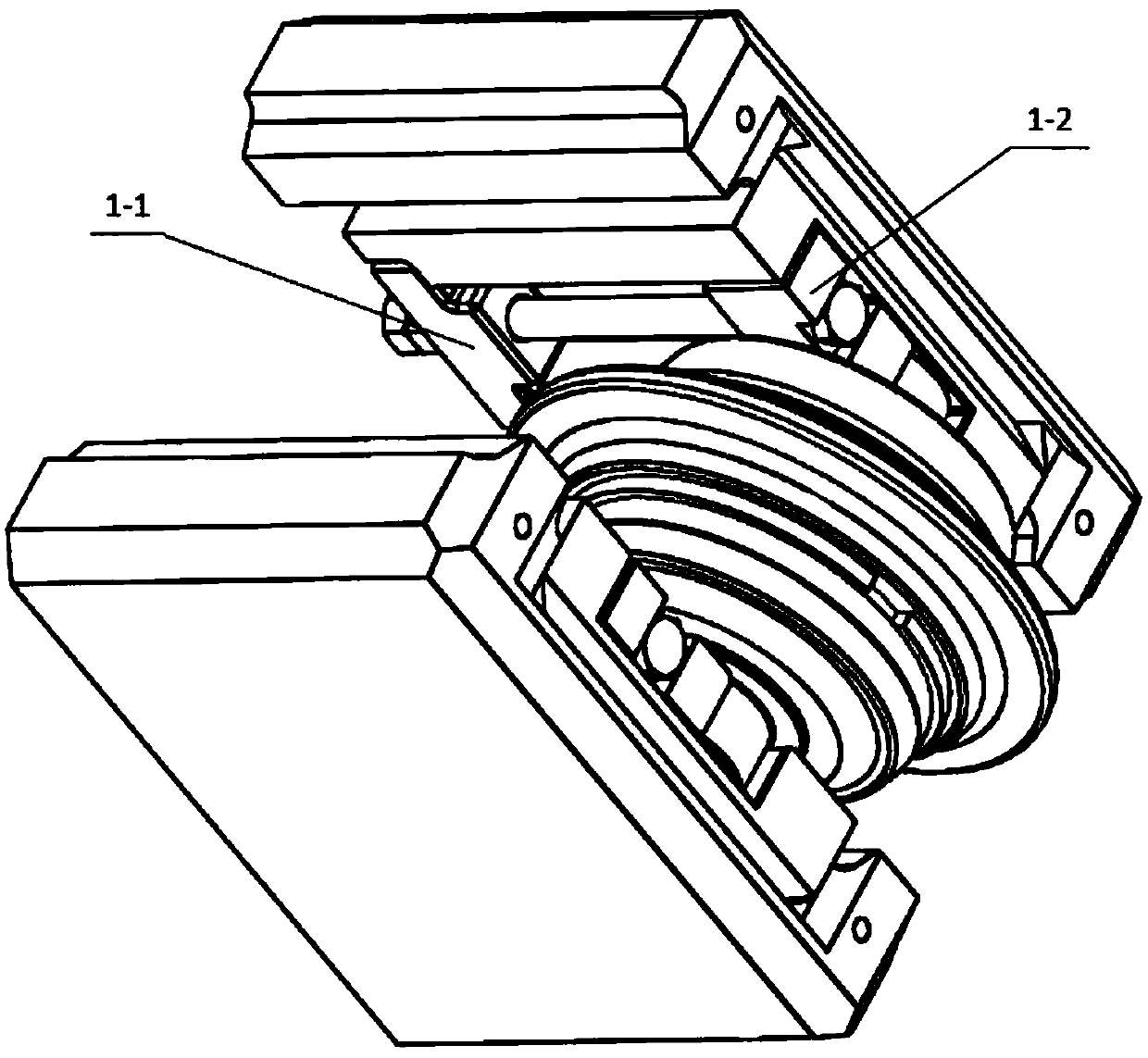

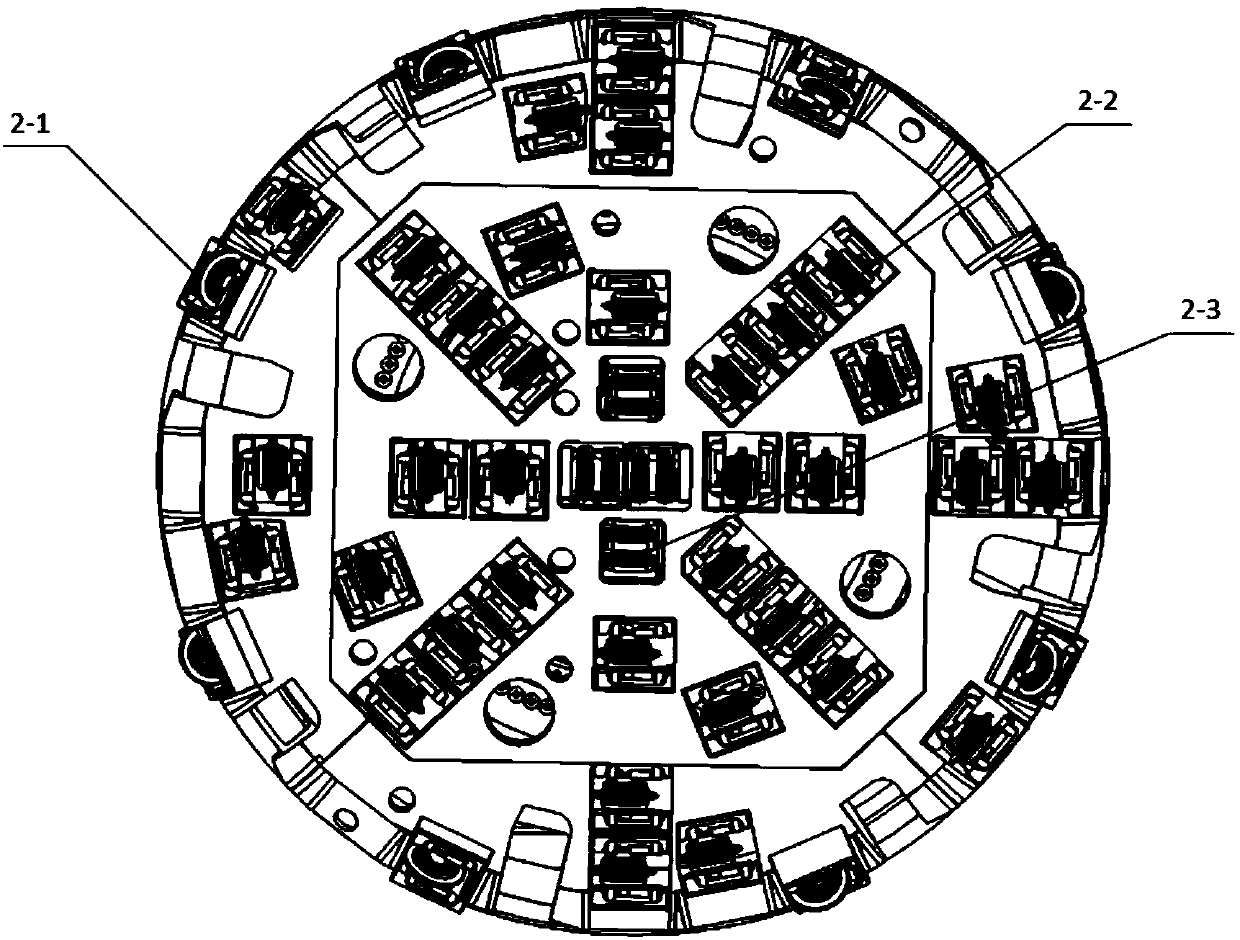

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the drawings and technical solutions of the present invention.

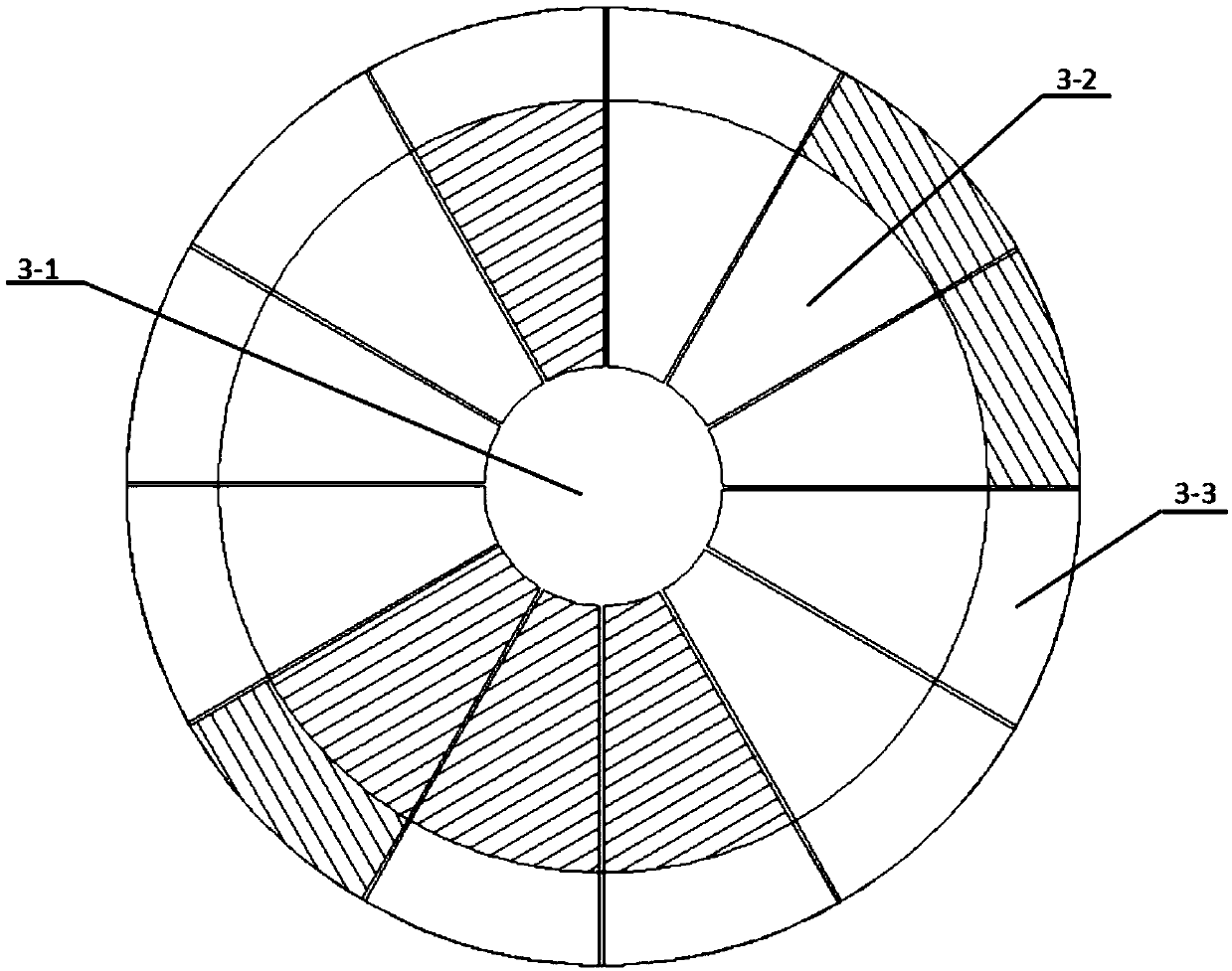

[0021] 1. Divide the TBM cutter head into different areas and number them.

[0022] Take the center of the cutterhead as the center, make a circle with the maximum distance between the center hob and the center of the cutterhead, and the minimum distance between the side hob and the center of the cutterhead as the radius, and divide the cutterhead into three areas in the radial direction. From the inside to the outside are the center hob area 3-1, the positive hob area 3-2 and the side hob area 3-3. Take the horizontal line passing through the center of the cutter head as the first thin plate, and take the first thin plate as the reference, divide the cutter head into several areas in the circumferential direction according to a certain angle value (this model takes 30° as an example), and divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com