Diaphragm material used for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and diaphragm materials, which is applied in the field of diaphragm materials for lithium-ion batteries and its preparation, and can solve the problems of easily damaged ceramic coated diaphragms, low thermal shrinkage rate of diaphragms, and poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

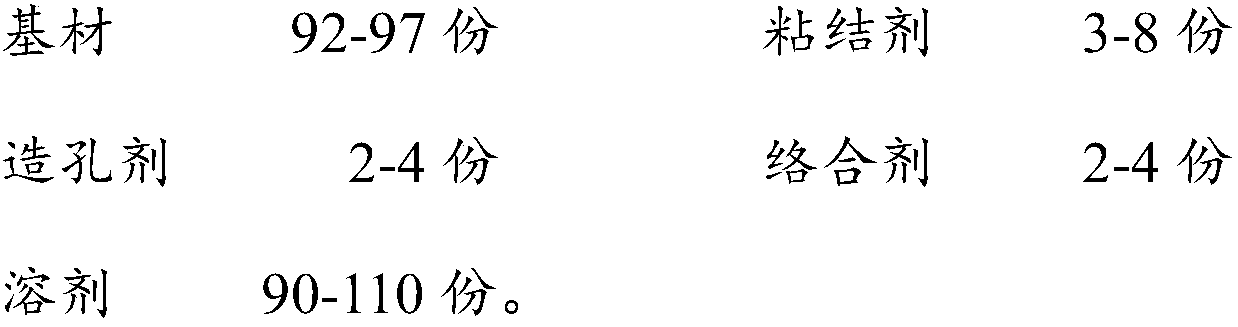

[0041] A diaphragm material for a lithium ion battery, the diaphragm material comprises by weight:

[0042]

[0043] The preparation method of separator material for lithium ion battery is as follows:

[0044] Put acetone and polyvinylidene fluoride into the planetary mixer in proportion, and mix and stir for 180 minutes at a stirring revolution speed of 15 r / min, a dispersion speed of 1500 r / min, and a temperature of 40°C to obtain a mixture a;

[0045] Add dibutyl phthalate to mixture a, stir at a stirring revolution speed of 20 r / min, a dispersion speed of 1500 r / min, and a temperature of 40°C for 30 minutes to obtain mixture b;

[0046] Add dimethylacetamide to mixture b, stir at a stirring revolution speed of 20 r / min, a dispersion speed of 1500 r / min, and a temperature of 40°C for 45 minutes to obtain mixture c;

[0047] Add SiO2 to the mixture c, stir at a stirring revolution speed of 20r / min, a dispersion speed of 1800r / min, a temperature of 30°C, a stirring vacuum...

specific Embodiment 2

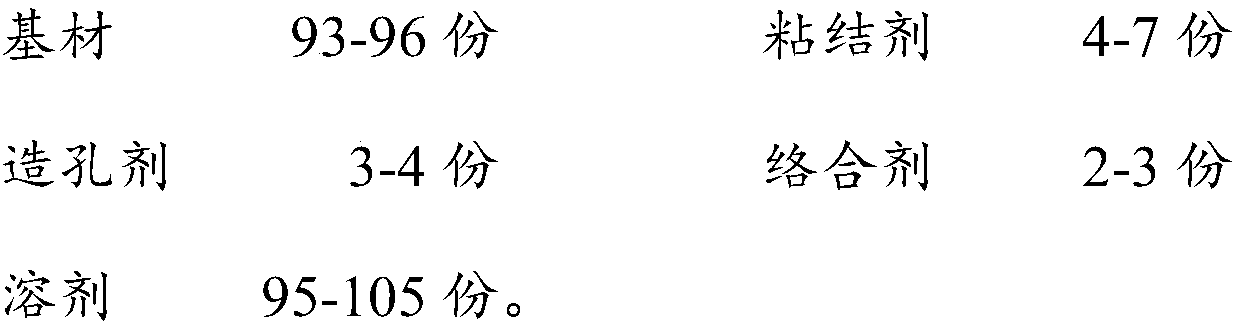

[0049] A diaphragm material for a lithium ion battery, the diaphragm material comprises by weight:

[0050]

[0051] The preparation method of separator material for lithium ion battery is as follows:

[0052] Put acetone and polyvinylidene fluoride into the planetary mixer in proportion, and mix and stir for 240 minutes at a stirring revolution speed of 20r / min, a dispersion speed of 2400r / min, and a temperature of 40°C to obtain a mixture a;

[0053] Add dibutyl phthalate to mixture a, stir at a stirring revolution speed of 15 r / min, a dispersion speed of 1500 r / min, and a temperature of 50°C for 45 minutes to obtain mixture b;

[0054] Add dimethylacetamide to mixture b, stir at a stirring revolution speed of 15 r / min, a dispersion speed of 1500 r / min, and a temperature of 30°C for 30 minutes to obtain mixture c;

[0055] Add SiO2 to mixture c, stir at a revolution speed of 20r / min, a dispersion speed of 2400r / min, a temperature of 40°C, a stirring vacuum of 0.095MPa, a...

specific Embodiment 3

[0057] A diaphragm material for a lithium ion battery, the diaphragm material comprises by weight:

[0058]

[0059] The preparation method of separator material for lithium ion battery is as follows:

[0060] Put ethanol and sodium carboxymethylcellulose into a planetary mixer in proportion, mix and stir for 190 minutes at a stirring revolution speed of 15 r / min, a dispersion speed of 1700 r / min, and a temperature of 41° C. to obtain a mixture a;

[0061] Add dicyclohexyl phthalate to mixture a, stir at a stirring revolution speed of 17 r / min, a dispersion speed of 1700 r / min, and a temperature of 30°C for 35 minutes to obtain mixture b;

[0062] Add triethanolamine to mixture b, stir at a stirring revolution speed of 18 r / min, a dispersion speed of 1800 r / min, and a temperature of 50°C for 35 minutes to obtain mixture c;

[0063] Add alumina to mixture c, stir at a stirring revolution speed of 25 r / min, a dispersion speed of 1900 r / min, a temperature of 32°C, a stirring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap