Universal wire clamp for power line

A power line, general-purpose technology, applied in circuits, electrical components, conductive connections, etc., can solve problems such as inability to apply cables of different diameters, restraint, troublesome disassembly and assembly of wire clips, etc., to improve practicability and versatility , reduce production costs, strengthen the effect of fixed restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

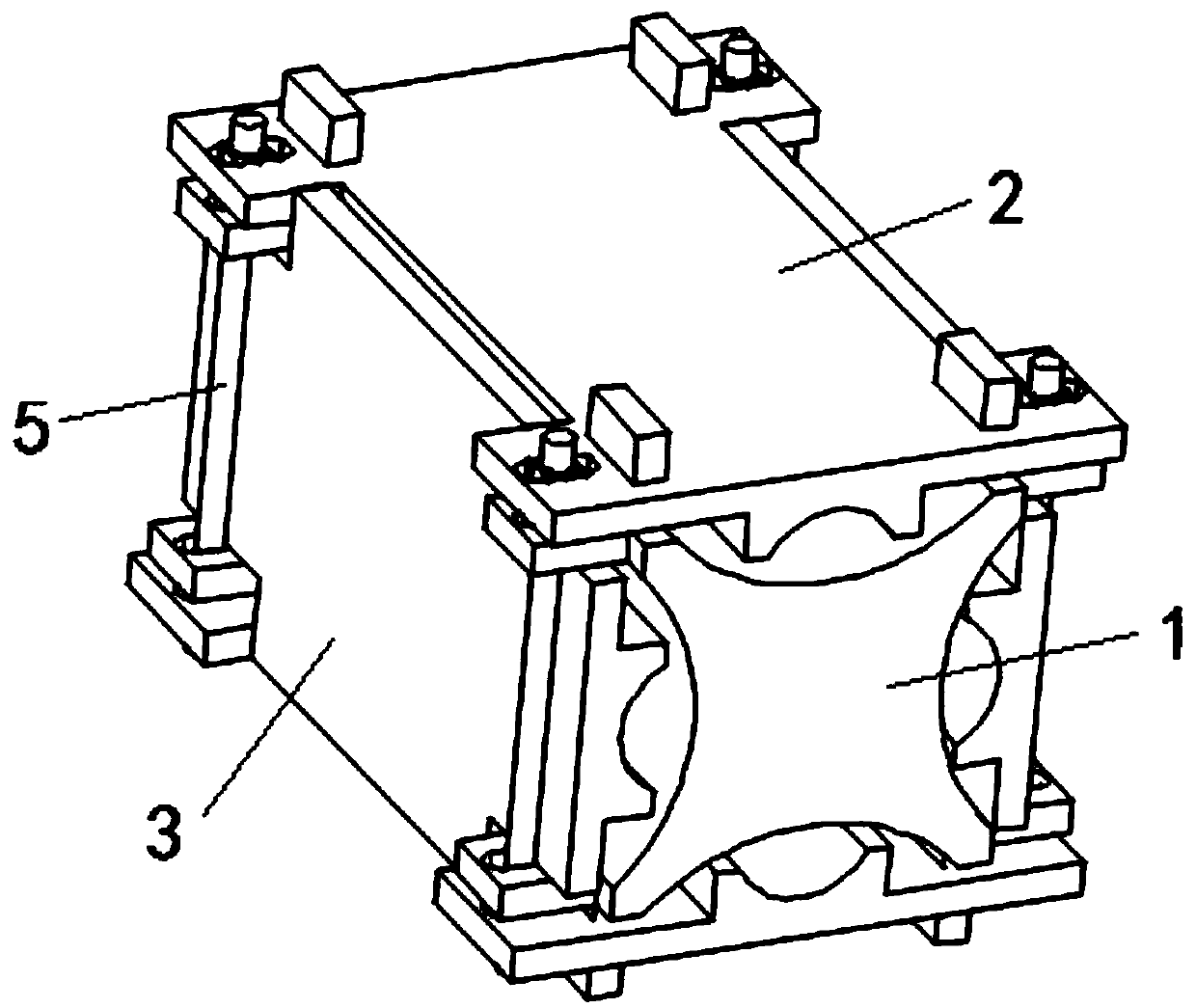

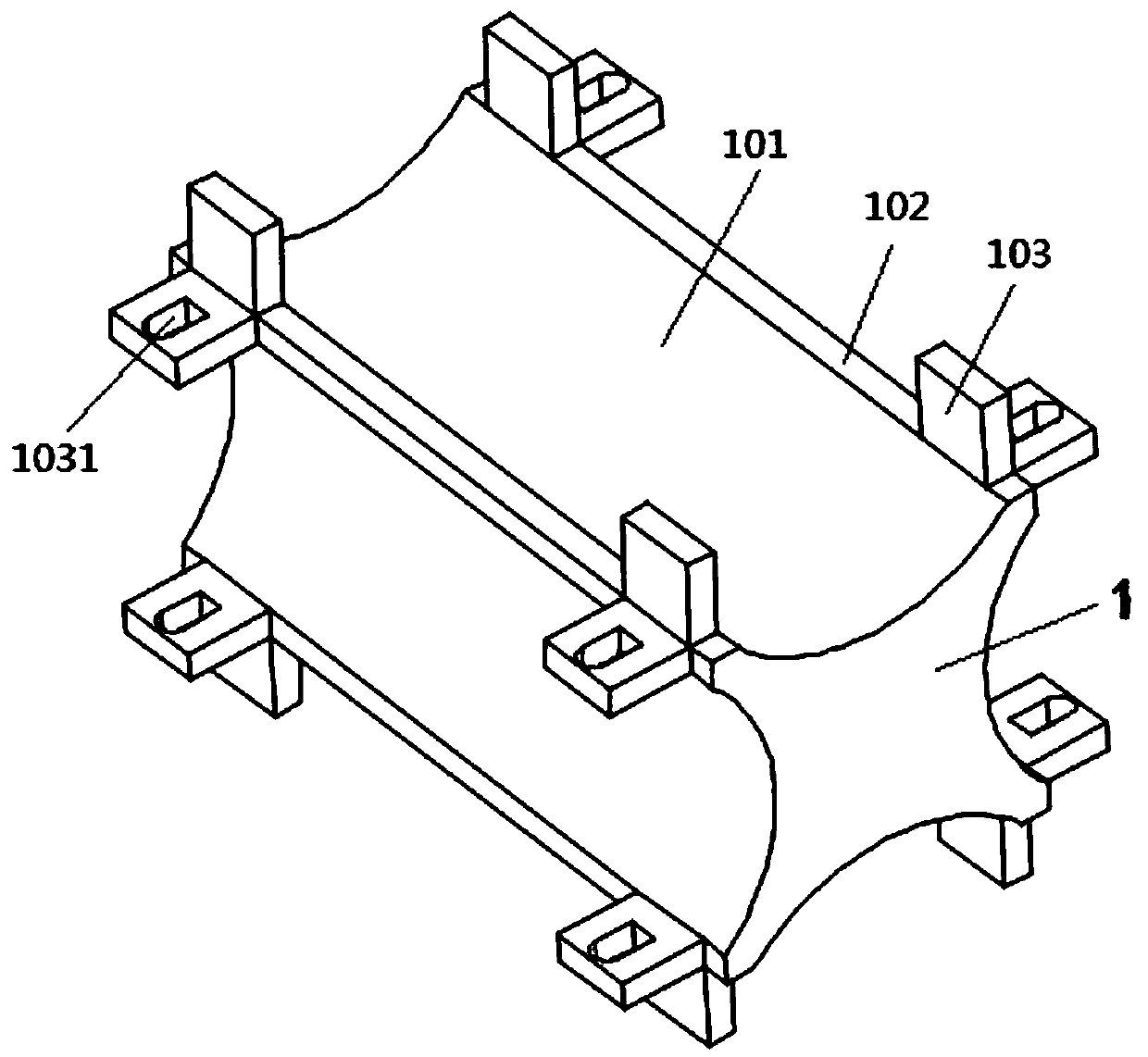

[0035] like Figure 1-2 As shown, the present invention is a general-purpose clamp for power lines, including a fixed inner core 1, a first cover plate 2 and a second cover plate 3, the fixed inner core 1 is a cuboid structure, and the fixed inner core 1 There is a first arc-shaped through groove 101 on the side, and the first arc-shaped through groove 101 makes the side of the fixed inner core 1 form a group of symmetrical strip surfaces 102, and the two ends of the strip-shaped surfaces 102 are symmetrically fixed with ear plates 103 ;

[0036] Wherein, a first straight notch 1031 is formed on the ear plate 103 on an opposite side of the fixed inner core 1, and the length direction of the first straight notch 1031 is parallel to the width direction of the fixed inner core 1;

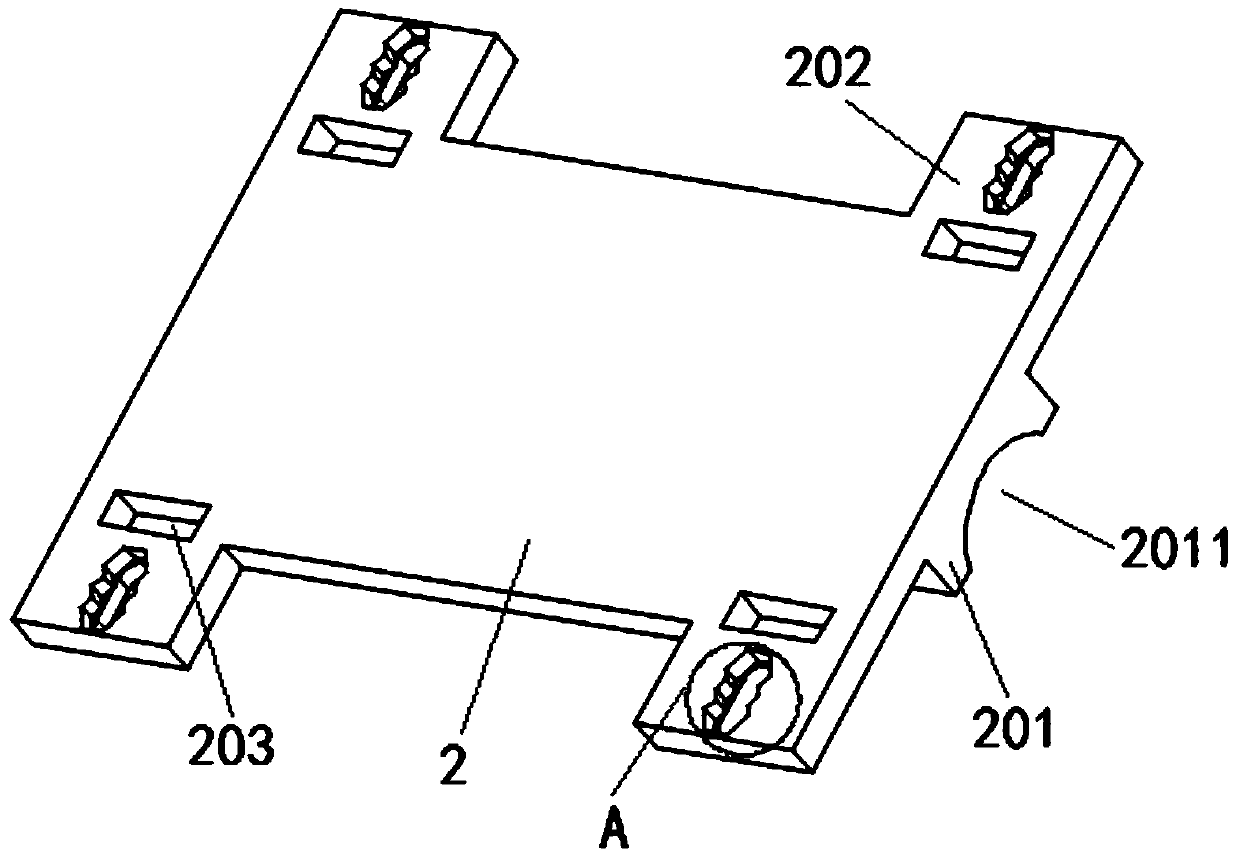

[0037] like Figure 3-6 As shown, both the first cover plate 2 and the second cover plate 3 are of cuboid structure; the lower surface of the first cover plate 2 is fixed with a clamping plate 201; a...

Embodiment 2

[0049] Pass the cable through the gap between the second arc-shaped slot 2011 and the first arc-shaped slot 101 and the gap between the third arc-shaped slot 3011 and the first arc-shaped slot 101, and then clamp the nut on the In the nut slot 2022, use a screwdriver to tighten the screws, so that the two first cover plates 2 are close to each other, and the two second cover plates 3 are close to each other, and finally the cables are clamped and fixed. This process is convenient for disassembly and assembly, and is convenient for people to install. Operation, suitable for cables of different diameters, reducing the cost of people manufacturing plate clamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com