Feeding system of lithium battery core winder

A winding machine and lithium battery cell technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor holding effect of electrode sheets, inability to move or disassemble the material bin, and affect the effect of clamping materials, etc., to achieve The universality and practicability are improved, the adjustment operation is convenient and quick, and the clamping action is smooth and coherent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

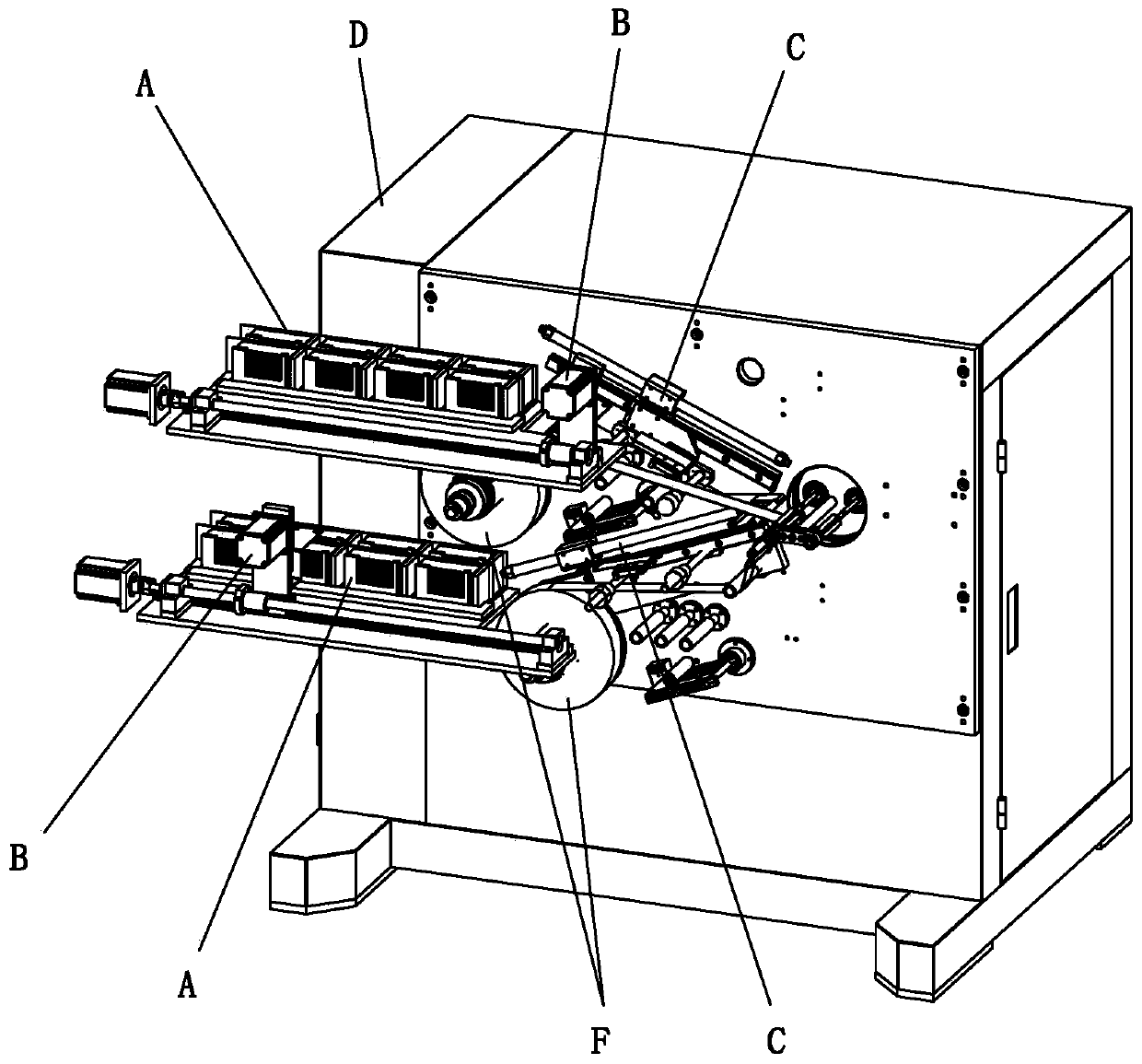

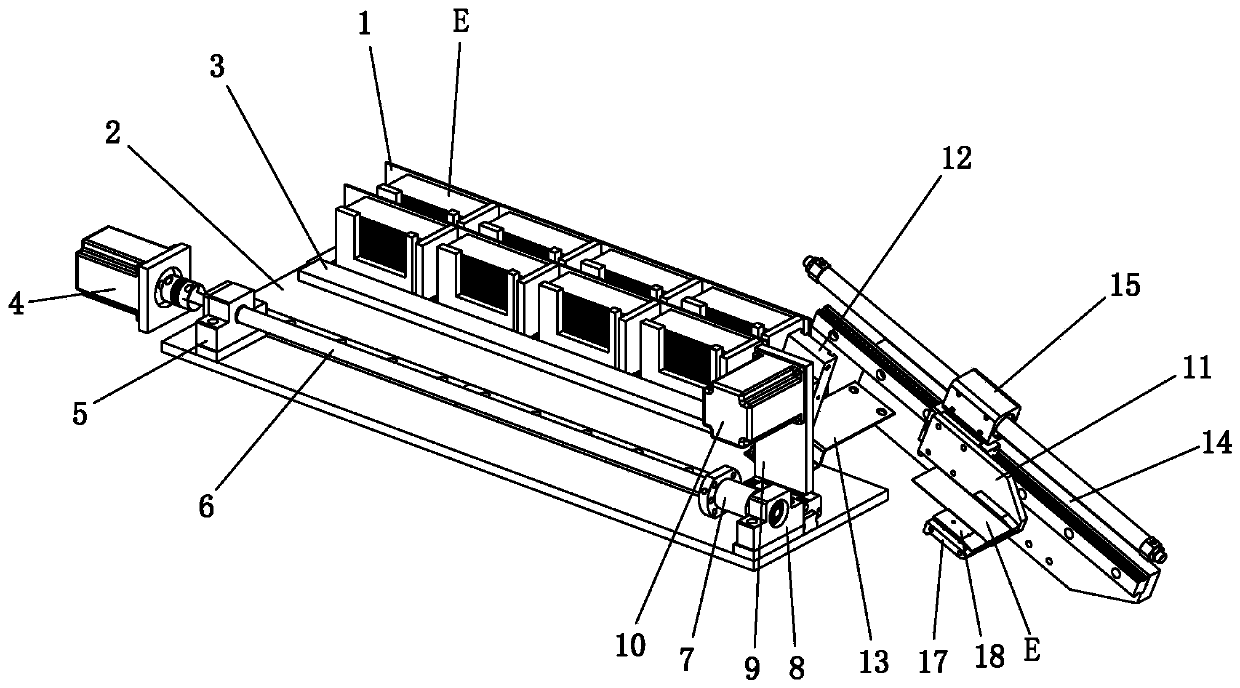

[0032] see Figure 1-Figure 11 , In the lithium battery winding machine involved in this embodiment, two sets of upper and lower feeding systems are set correspondingly to load the positive and negative electrode sheets E. The feeding system is set on the main body D of the winding machine, below the feeding system A matching diaphragm roll F is provided.

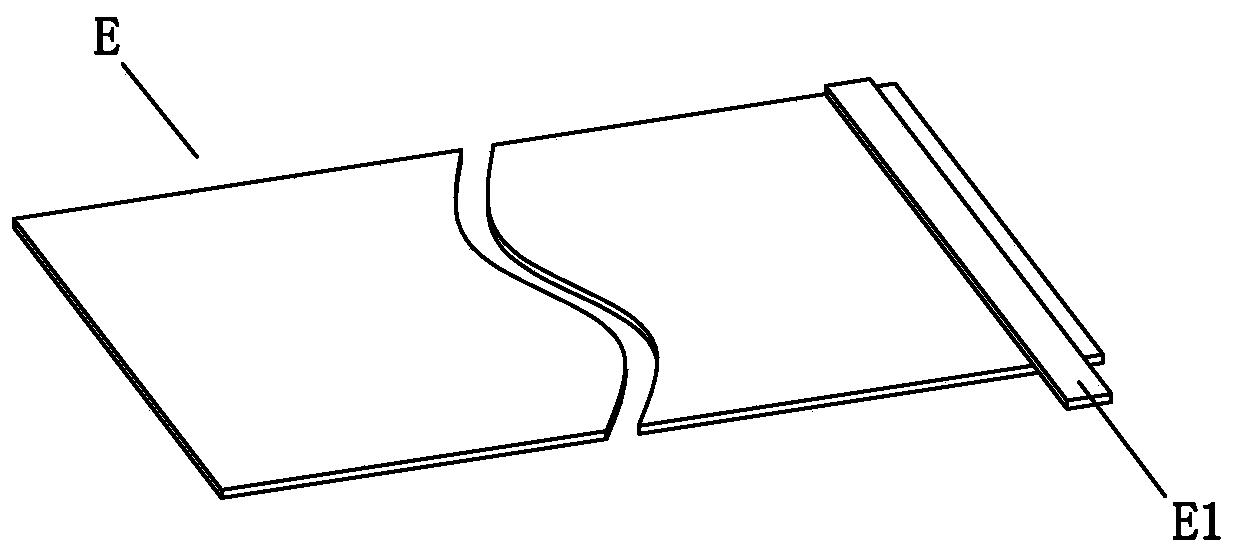

[0033] The feeding system includes a storage mechanism A for storing electrode sheets E, a feeding mechanism B for picking up electrode sheets E, and a feeding mechanism C for transporting electrode sheets E; wherein, the storage mechanism A includes two sets of storage The material frame 1 is detachably arranged on the material storage platform 2; the material storage frame 1 includes a material storage base plate 101, four partitions 102 and four baffles 103, and the partitions 102 and the baffles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com