Constant force mechanism based banana harvesting device capable of automatically adapting to banana tree stem

A self-adaptive, banana technology, applied in application, food processing, food science and other directions, can solve the problems of poor radial self-adaptation and bending self-adaptability, large clamping force of ear bar, low work efficiency, etc. The effect of reducing artificial physical strength, reducing rigid impact, and rotating smoothly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

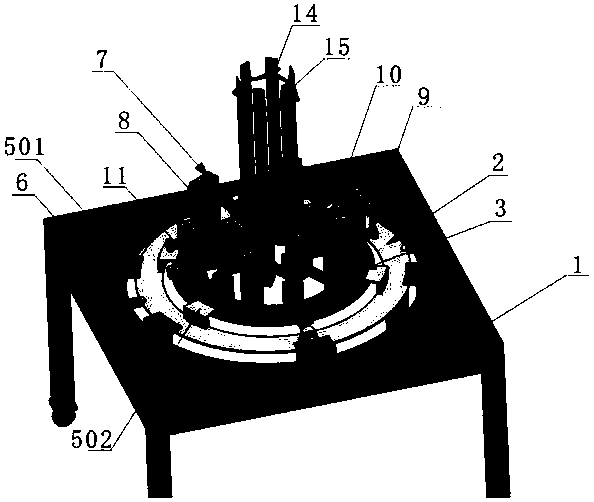

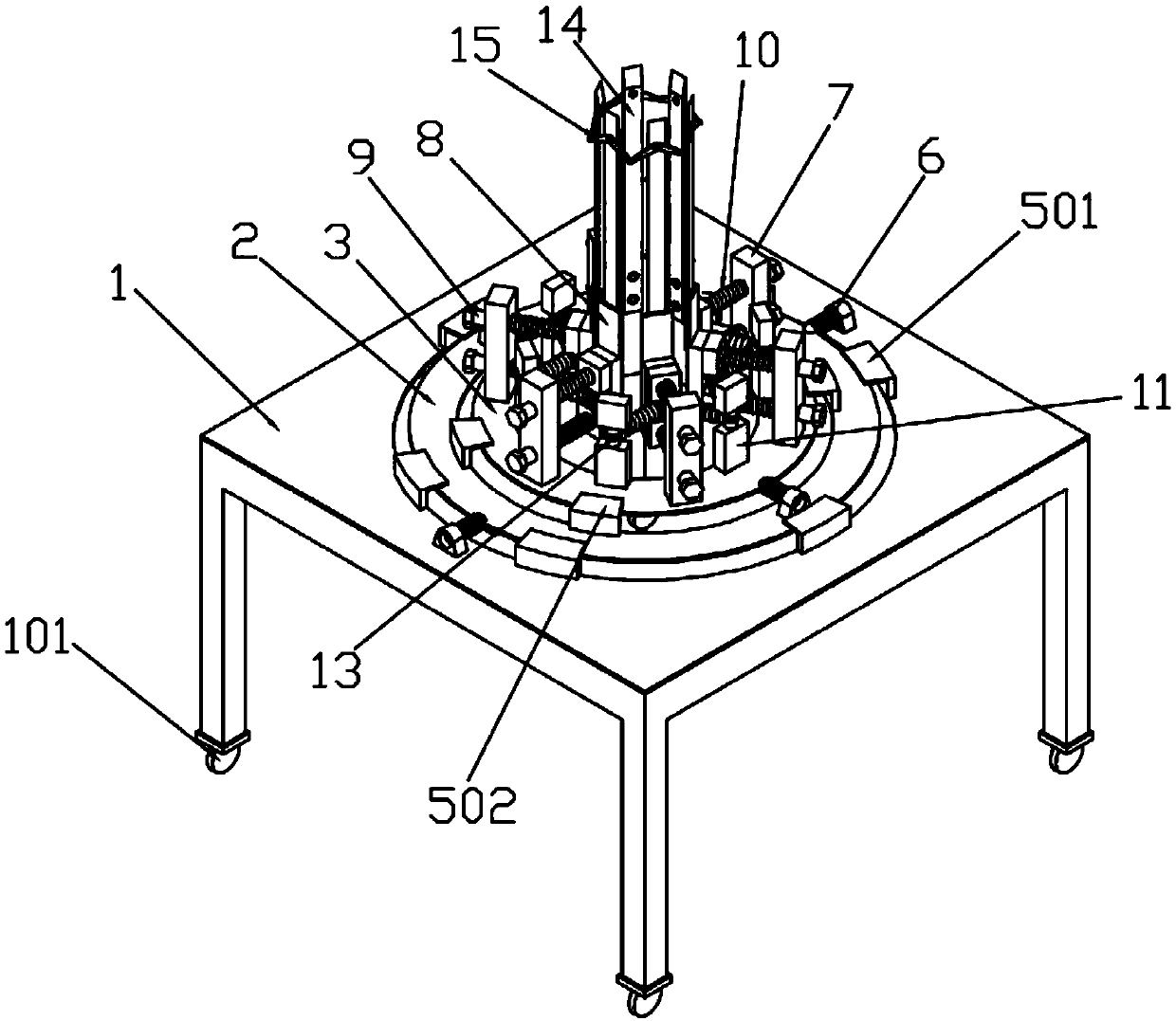

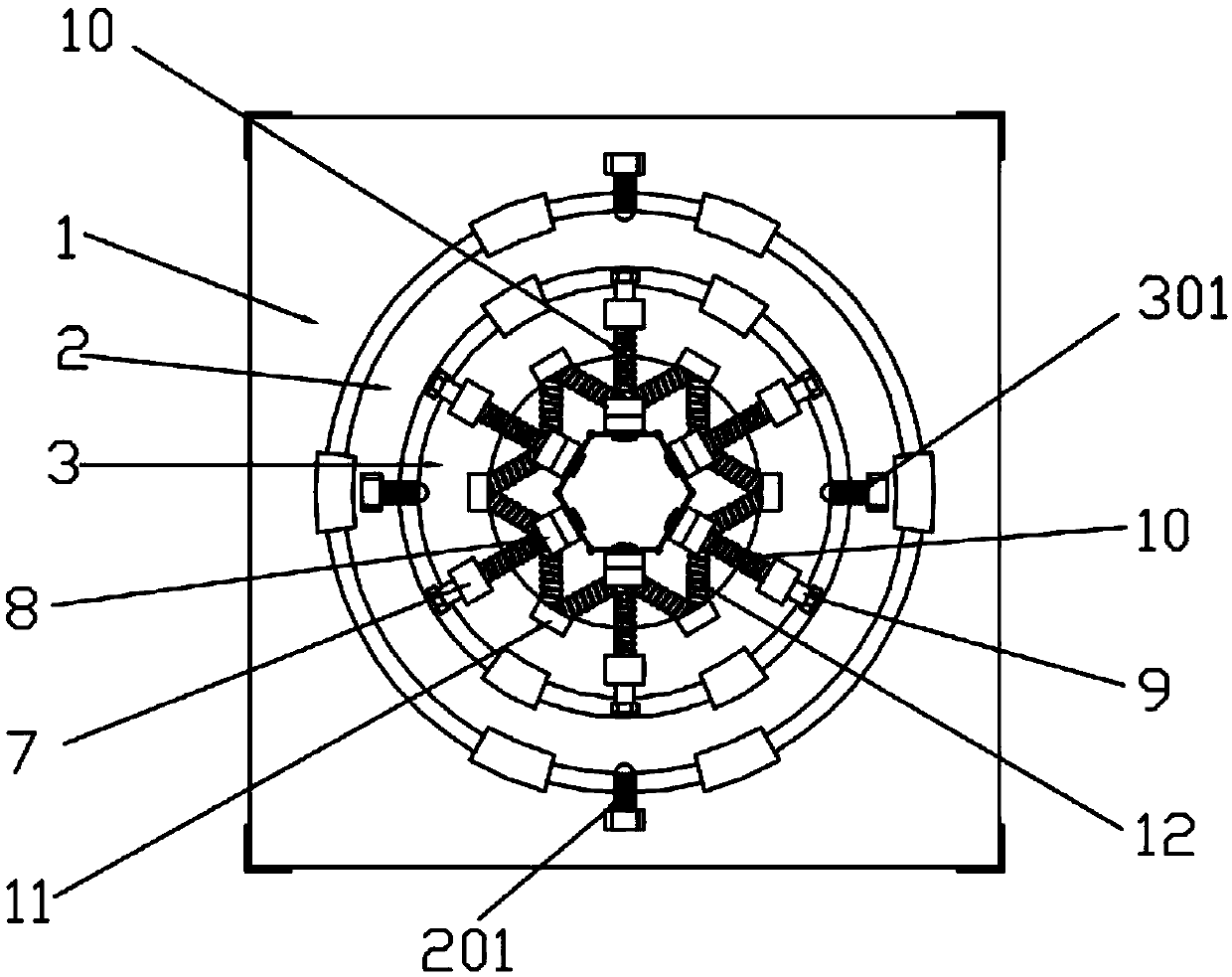

[0020] see Figure 1 to Figure 3 As shown, the banana combing device based on the constant force mechanism provided by the present embodiment that can adapt to the banana stem includes a frame 1, an outer cutter head 2, an inner cutter head 3, a first fixed shaft 201, and a second fixed shaft. Shaft 301, first lifting block 501, second lifting block 502, torsion spring 6, fixed frame 7, hard blade mounting frame 8, movable guide rod 9, horizontal compression spring 10, public column 11, oblique compression Spring 12, class shock absorber joint 13, hard blade 14, soft blade 15; Four lockable universal casters 101 are installed on the bottom of frame 1, and the center of frame 1 is formed with a through hole; The cutter head 2 has a ring structure, and the diameter of the outer circle of the ring is smaller than the diameter of the above-mentioned through hole. The outer cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com