Surface cleaning base

A surface cleaning and base technology, applied to cleaning equipment, suction nozzles, vacuum cleaners, etc., can solve problems such as insufficient reliability of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

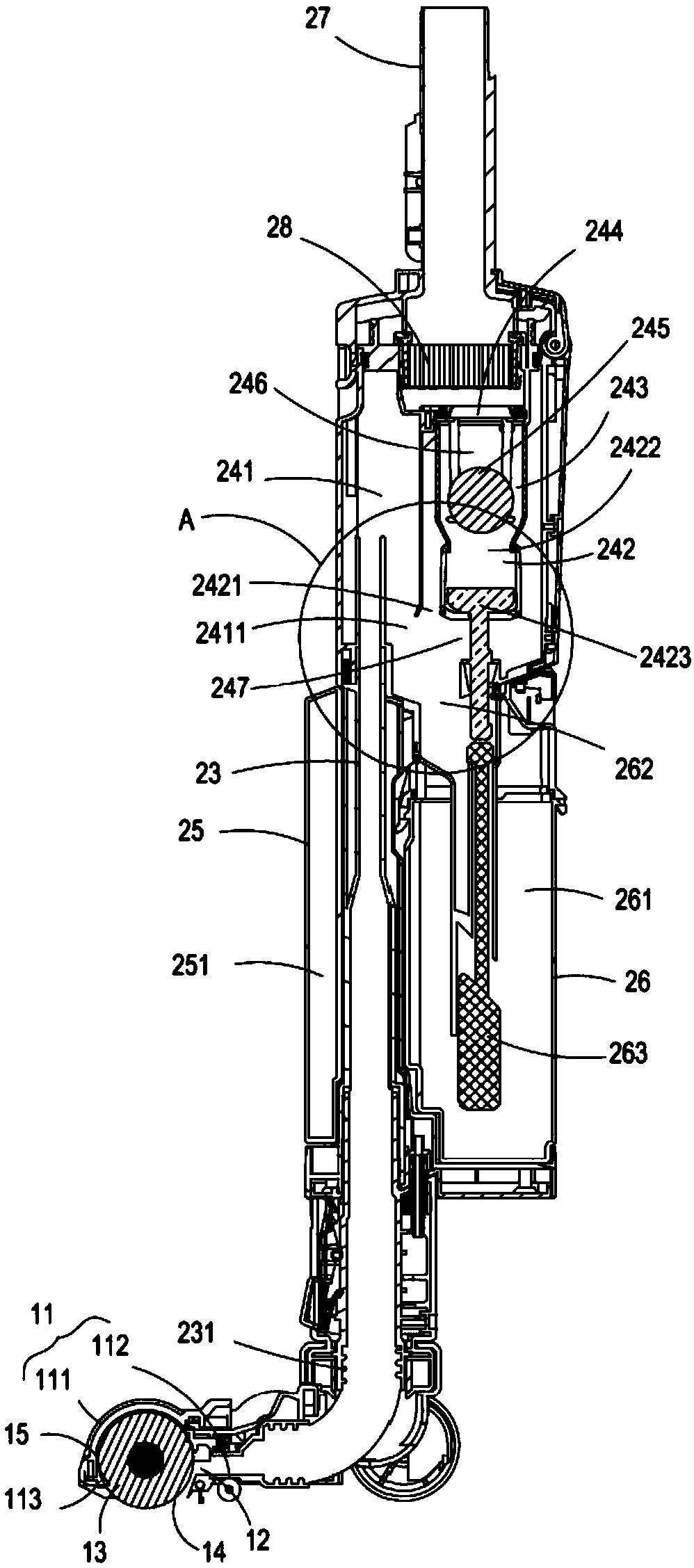

[0026] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

[0027] For purposes of description relative to the figures, the terms "upper", "lower", "right", "left", "rear", "front", "vertical", "horizontal", "inner", "outer" and Its derivative shall refer to the user's perspective from behind the Surface Cleaning Base 1 (e.g. figure 1 orientation shown in ).

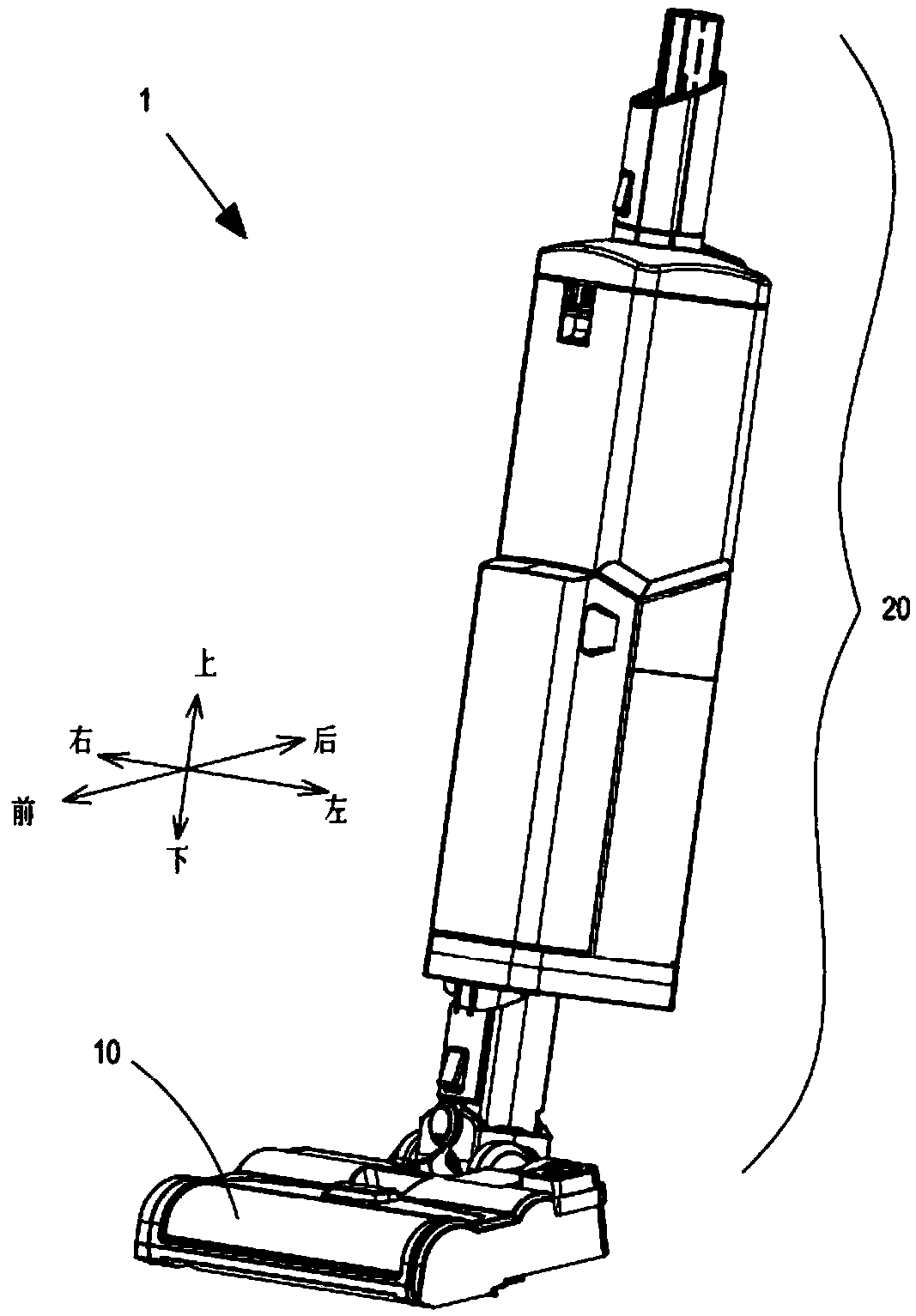

[0028] figure 1 is a schematic perspective view of a surface cleaning base 1 attached to a vacuum cleaner for use, which includes a cleaning head 10 adapted to move over the surface to be cleaned and a lower portion rotatably connected to the cleaning head 10 Uprights 20.

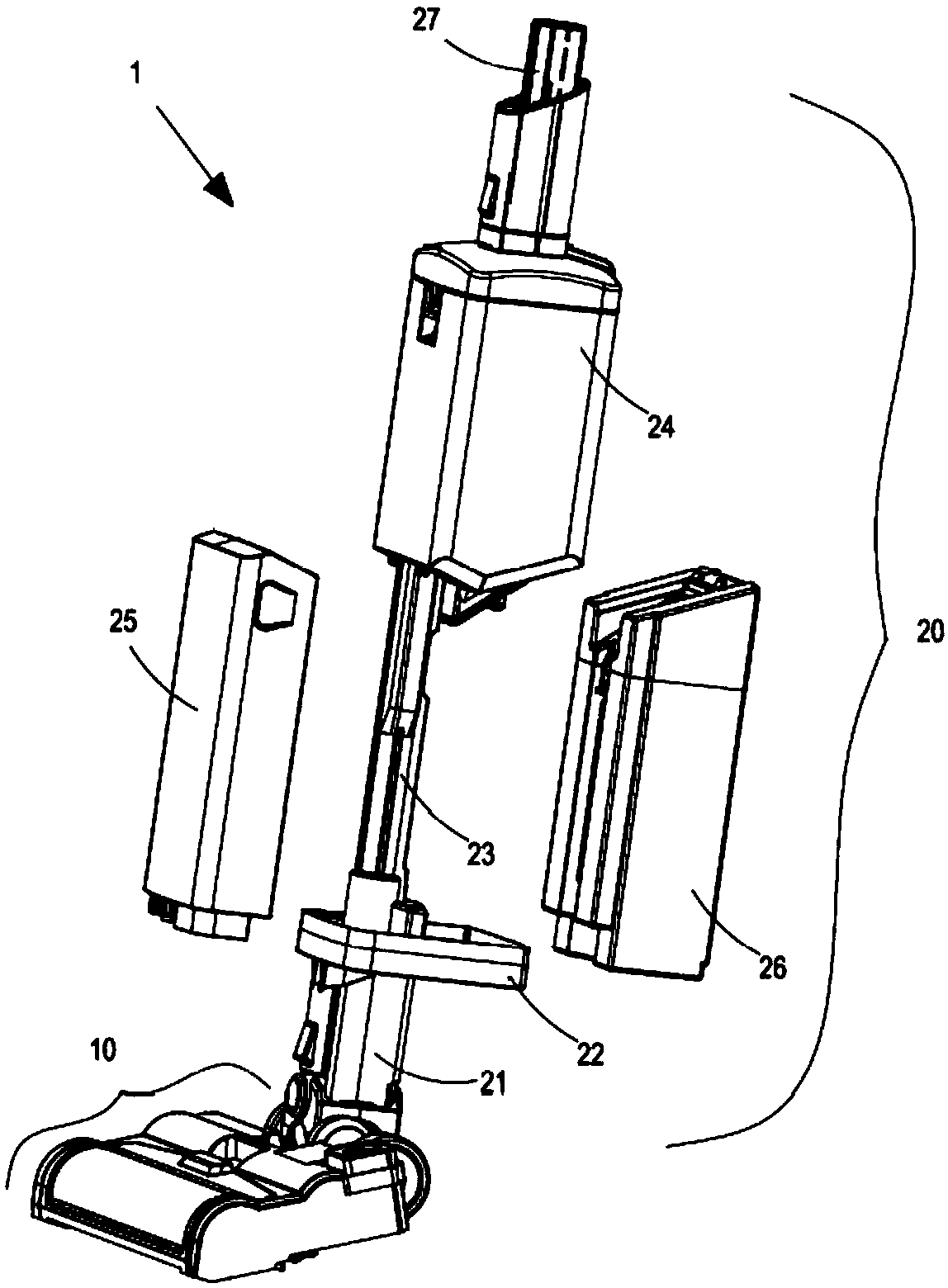

[0029] Such as figure 2 The exploded schematic view of the surface cleaning base 1 shown, the upright part 20 includes a lower connection head 21, a lower support pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap