Distal fibula C-type bone fracture band lateral wing locking setting structure

A flank and fibula technology, applied in the field of distal fibula type C fracture with flank locking bone structure, can solve the problems of weakened holding force, easy loosening of screws, and influence on treatment effect, so as to improve fixation strength, increase surgical options, and skin tension small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below with reference to the drawings and specific embodiments.

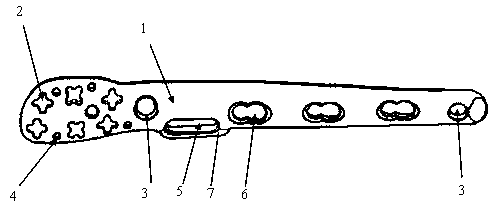

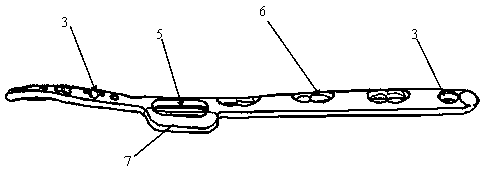

[0017] Such as Figure 1 to Figure 3 As shown, the C-type fracture of the distal end of the fibula with flank locking bone structure of the present invention includes: a locking bone plate 1, a universal locking screw 8, a locking screw and a compression screw 9; The universal locking hole 2, locking hole 3 and guide pin hole 4 of the plate, the stem of the locking bone plate is provided with a side wing 7 protruding to one side, and the side wing is provided with a side wing sliding pressure hole 5 penetrating through the locking bone plate, and the locking bone plate The cadre is also provided with a locking pressure hole 6 and a locking hole 3 that go through the locking bone plate; the universal locking screw, the locking screw and the pressure screw are respectively connected with the universal locking hole, the locking hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com