Absorbing fine desulfurization agent, preparation method and application thereof

A technology of fine desulfurization and activated carbon, which is applied in the fields of refining hydrocarbon oil, chemical instruments and methods, and other chemical processes to achieve the effect of easy regeneration and high sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

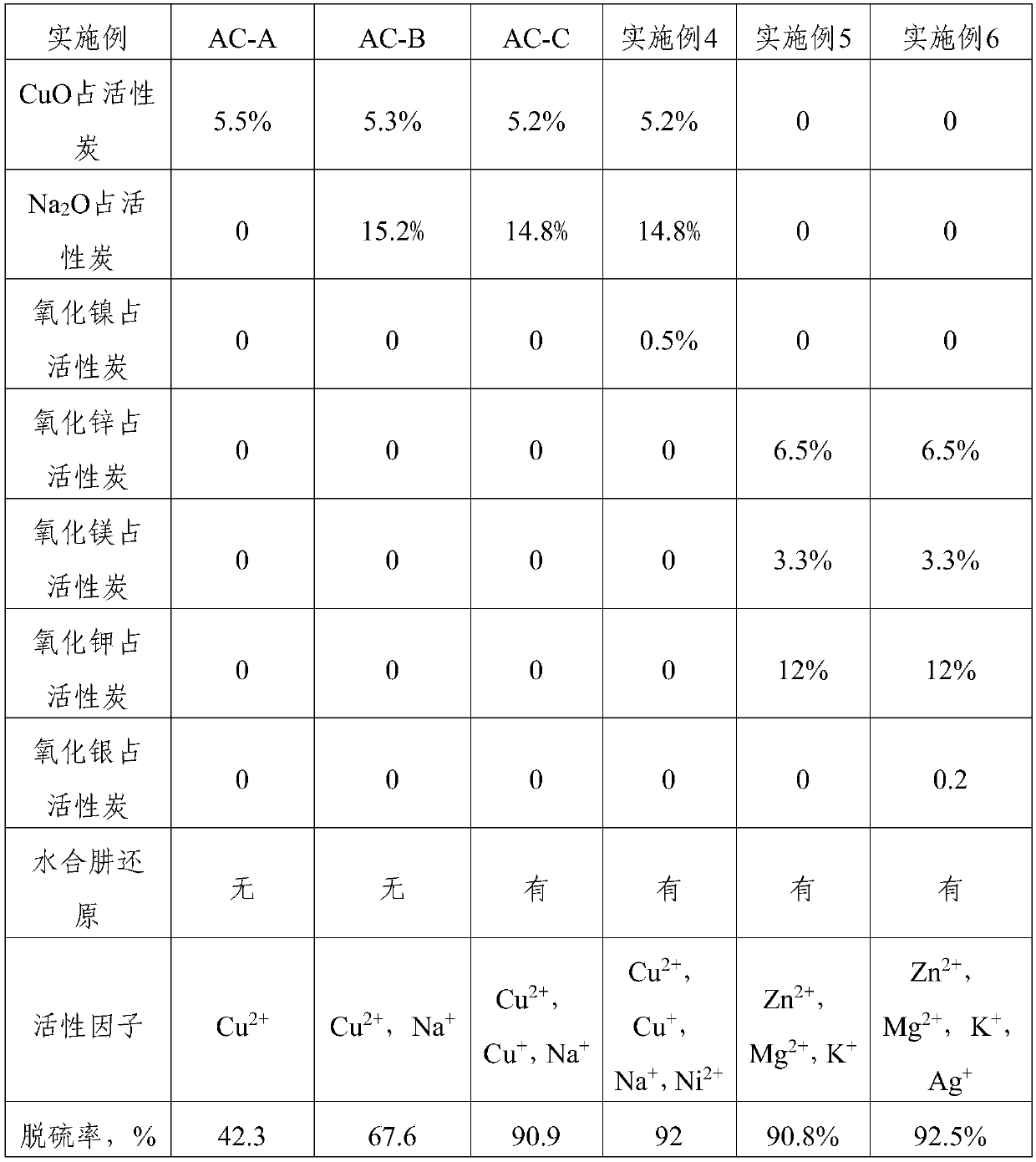

Examples

Embodiment 1

[0038] This embodiment provides an adsorption fine desulfurizer, which specifically includes the following steps:

[0039] After the activated carbon was sieved to obtain 30 mesh particles, 0.5mol / L Cu(NO 3 ) 2 The equal volume of the solution was impregnated on the activated carbon carrier, so that the amount of CuO accounted for 5.5% of the total weight of the activated carbon, placed at room temperature for 6 h, then dried at 120 °C for 8 h, and finally dried at 400 °C under N 2 Roasting and activating treatment for 2 hours under gas protection, the adsorption fine desulfurizer A is obtained, which is denoted as AC-A;

[0040] Among them, the specific surface area of activated carbon is 1000m 2 / g, the micropore volume is 85%, and the micropore diameter is 25A.

Embodiment 2

[0042] This embodiment provides an adsorption fine desulfurizer, which specifically includes the following steps:

[0043] After the activated carbon was sieved to obtain 30 mesh particles, 0.5mol / L Cu(NO 3 ) 2 The solution is impregnated on the activated carbon support in equal volume, so that the amount of CuO accounts for 5.3% of the total weight of the activated carbon, placed at room temperature for 6h, and then dried at 110°C for 12h, and quickly added 0.6mol / L NaOH aqueous solution at room temperature to make Na 2 The amount of O accounts for 15.2% of the total weight of activated carbon, stirred for 30min, then dried at 120°C for 12h, and finally heated at 400°C under N 2 Roasting and activating treatment for 2 hours under air protection, the adsorption fine desulfurizer B is obtained, which is denoted as AC-B;

[0044] Among them, the specific surface area of activated carbon is 1000m 2 / g, the micropore volume is 85%, and the micropore diameter is 25A.

Embodiment 3

[0046] This embodiment provides an adsorption fine desulfurizer, which specifically includes the following steps:

[0047] After the activated carbon was sieved to obtain 30 mesh particles, 0.5mol / L Cu(NO 3 ) 2 The solution is impregnated on the activated carbon carrier in equal volume, so that the amount of CuO accounts for 5.2% of the total weight of the activated carbon, placed at room temperature for 6h, and then dried at 110°C for 12h, and quickly added 0.6mol / L NaOH aqueous solution at room temperature to make Na 2 The amount of O accounted for 14.8% of the total weight of activated carbon, stirred for 30min, added 0.3mol / L hydrazine hydrate aqueous solution, reacted for 1h, filtered and washed, dried at 80°C for 12h, and finally dried at 400°C under N 2 Roasting and activating for 4 hours under air protection, the adsorption fine desulfurizer C is obtained, which is denoted as AC-C;

[0048] Among them, the specific surface area of activated carbon is 1000m 2 / g, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com