Tongs for wrapping and riveting arm rod and scraping rod of automobile windscreen wiper

A wiper and arm technology, applied in the field of automobile manufacturing, can solve the problems of high specialization, time-consuming, material consumption, etc., and achieve the effects of mass production, low loss cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

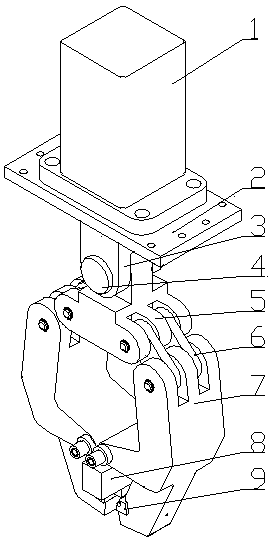

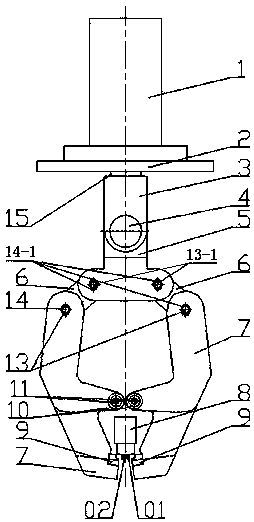

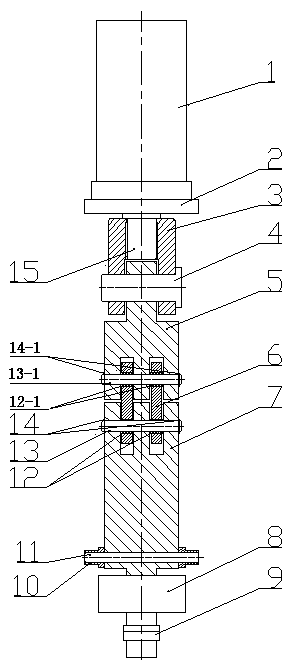

[0018] like figure 1 , figure 2 and image 3 Among them, a pliers for wrapping and riveting an automobile wiper arm rod and a scraper rod, including a hydraulic cylinder 1, a fixing plate 2, a Y-shaped joint 3, a tray 5, a clamp handle 7, a mold 9, a cushion block 8, a piston rod 15, a hydraulic The cylinder 1 exerts force outward through the piston rod 15, the hydraulic cylinder 1 is fixed on the fixed plate 2, and a Y-shaped joint 3 is arranged under the fixed plate 2, and the piston rod 15 and the Y-shaped joint 3 are threaded. A tray 5 is provided below the Y-shaped joint 3, and the Y-shaped joint 3 and the tray 5 are connected together through a pin shaft 4. A clamp handle 7 is provided below the tray 5, and the tray 5 is connected with the clamp handle 7 through a connecting rod 6. A mold 9 is provided below the handle 7, and the mold 9 is connected with the clamp handle 7 by bolts, and a spacer 8 is provided on the top of the mold 9. The mold 9 rotates together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com