Automatic O-ring picking and feeding mechanism applicable to different sizes

An automatic pick-up and O-ring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy detachment of pre-supporting claws, easy falling off, complicated feeding process, etc., to ensure stability and high efficiency Sexuality, reducing labor input costs, and speeding up the effect of fast feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

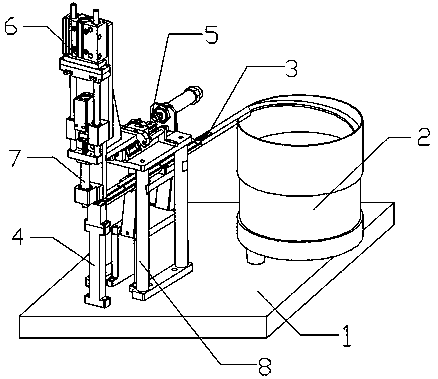

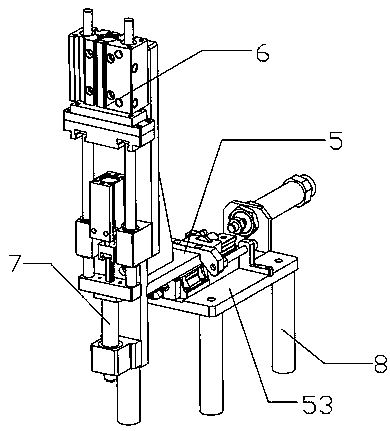

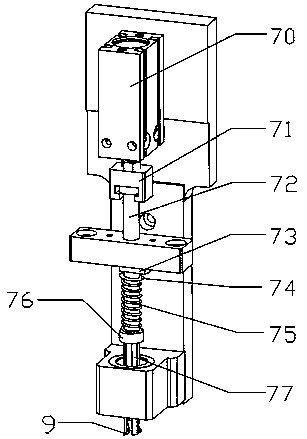

[0027]Embodiment 1, an O-ring automatic pick-up and feeding mechanism suitable for different sizes, including a workbench 1, an O-ring feeding device on the workbench 1 and a pick-up device located on the front side of the O-ring feeding device Material device, the front side of the picking and feeding device is provided with a rotating disk module, and the picking and feeding device picks up the O-ring at the end of the O-ring feeding device and places it in the positioning carrier on the rotating disk module; the picking The feeding device comprises a support frame 8, a horizontal movement module 5, a vertical lifting module 6 and a pick-up module 7, the fixed end of the horizontal movement module 5 is installed on the top of the support frame 8, and the working end of the horizontal movement module 5 Fixedly connected with the upper fixed end of the vertical lift module 6, the pick-up module 7 is positioned at the lower fixed end of the vertical lift module 6; hole socket; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com