Brick machine plus material device structure

A technology of a fabric maker and a brick making machine, which is applied to supply devices, manufacturing tools and other directions, can solve the problems of inconvenient use, uneven delivery, and difficult control of the delivery amount, and achieves the effect of solving inconvenient use and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

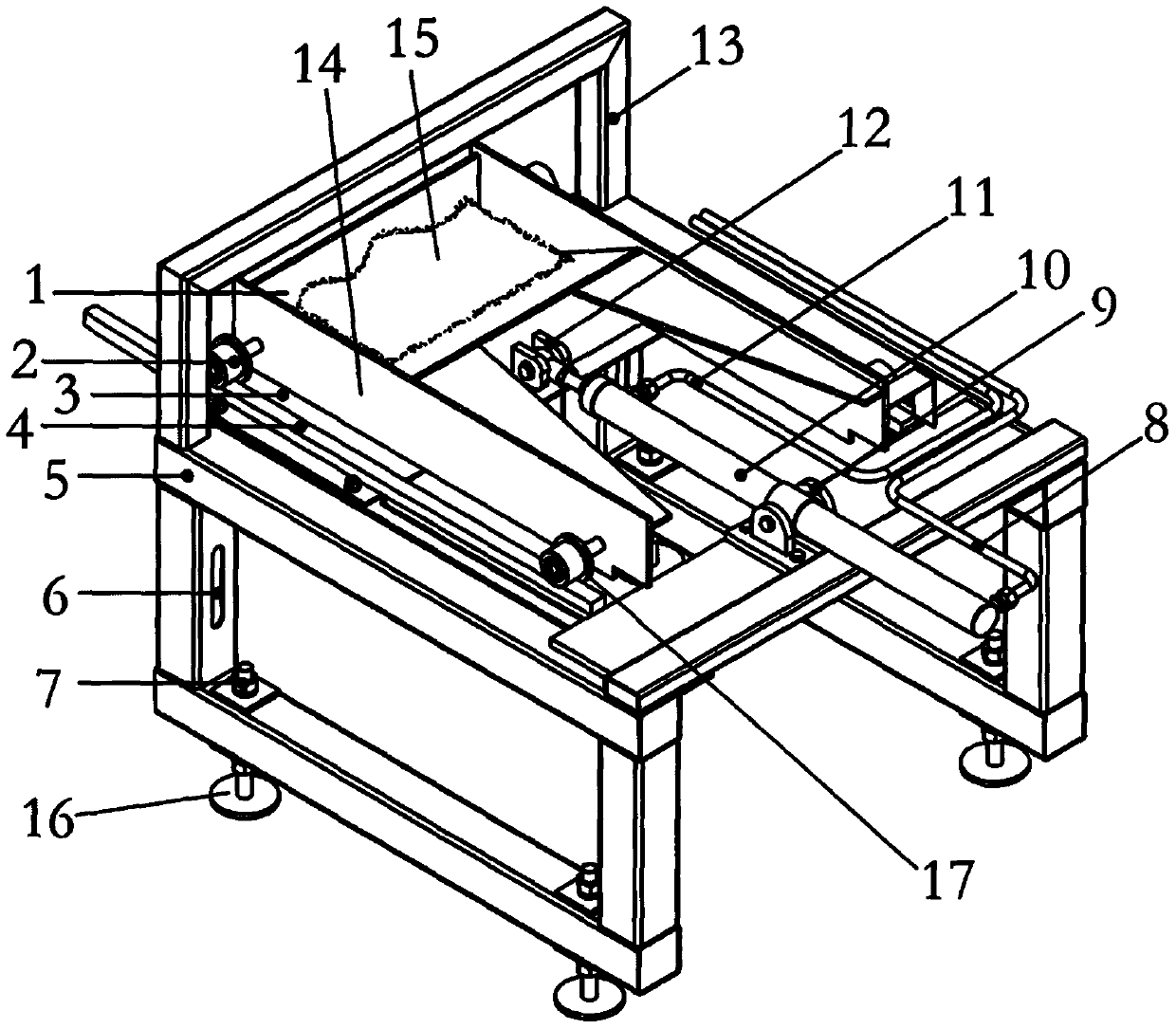

[0015] Embodiment 1: According to figure 1 , a brick machine finishing device structure, which includes a material bin 1 corresponding to the level of the brick machine mould; the top of the material bin is open, and the bottom is a strip-shaped outlet; The bottom pallet 3; the bottom pallet is provided with a frame 5, and the frame is connected with the brick machine through the connecting hole 6; the two sides of the storage bin 1 are respectively provided with side baffles 14; The side baffle is provided with the rollers 2 connected by rotation; the frame is provided with the guide rails 4 corresponding to the rollers; the push-pull oil top 10 is arranged at the back of the storage bin 1; the push-pull oil top 10 passes through the fixed seat 9 Fix it on the cross brace in the middle of the rack.

[0016] Put the material 15 in the material bin 1, and after the brick machine presses the adobe in the mould, the mold pressure head is lifted, at this time, the push-pull oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com