Drilling system of glass drilling machine

A drilling machine and glass technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of inconvenient weight, concentrated force on the glass to be punched, and unfavorable use, so as to facilitate the drilling work and avoid the position Offset, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

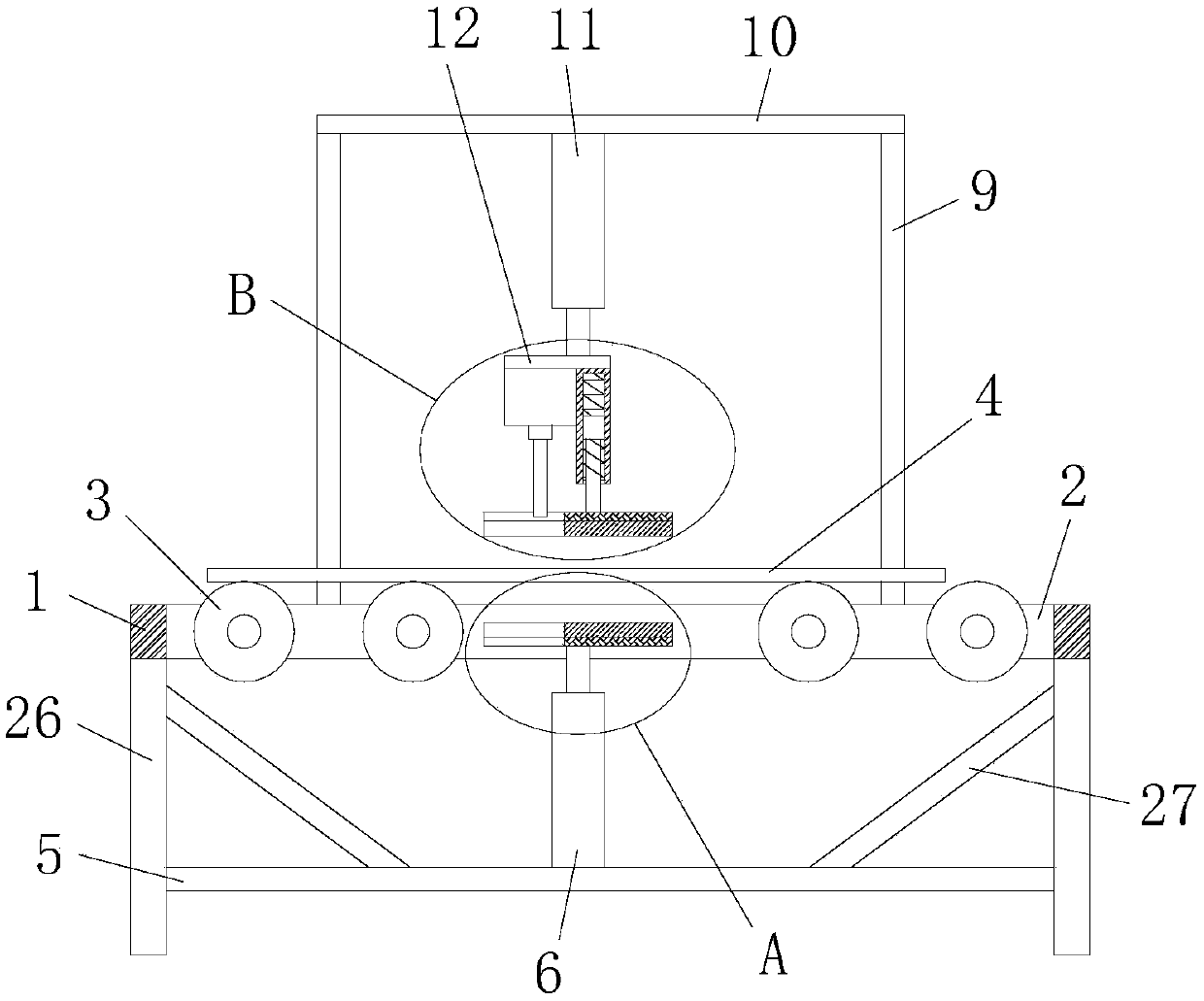

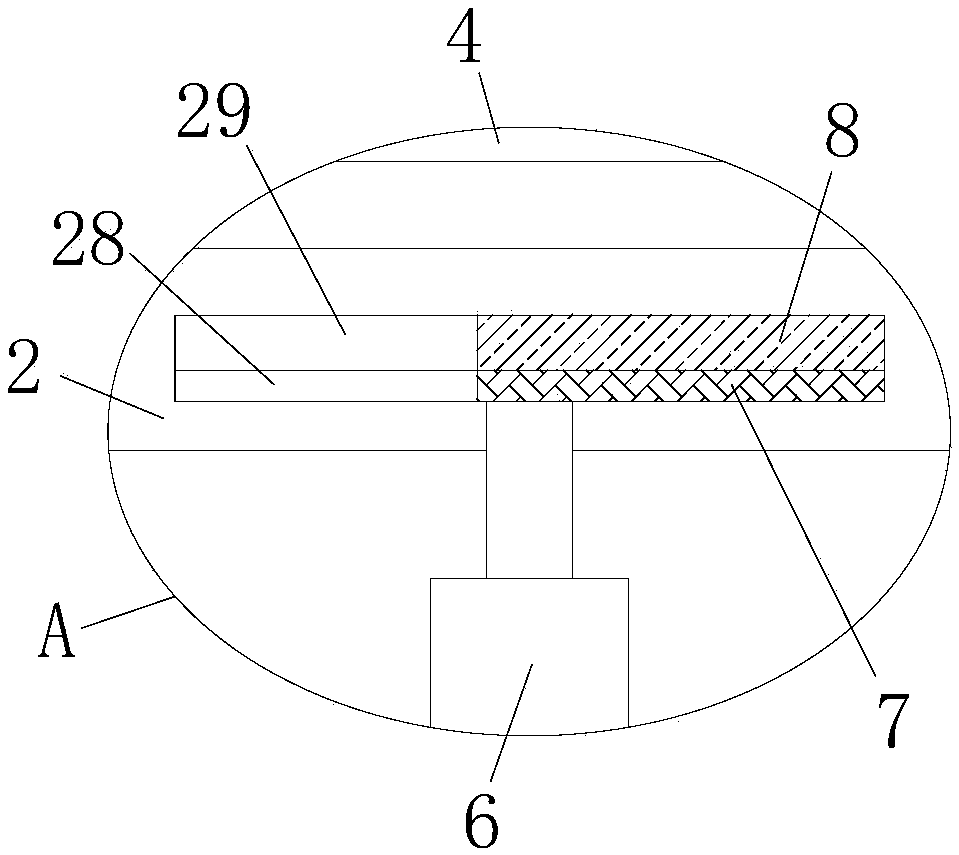

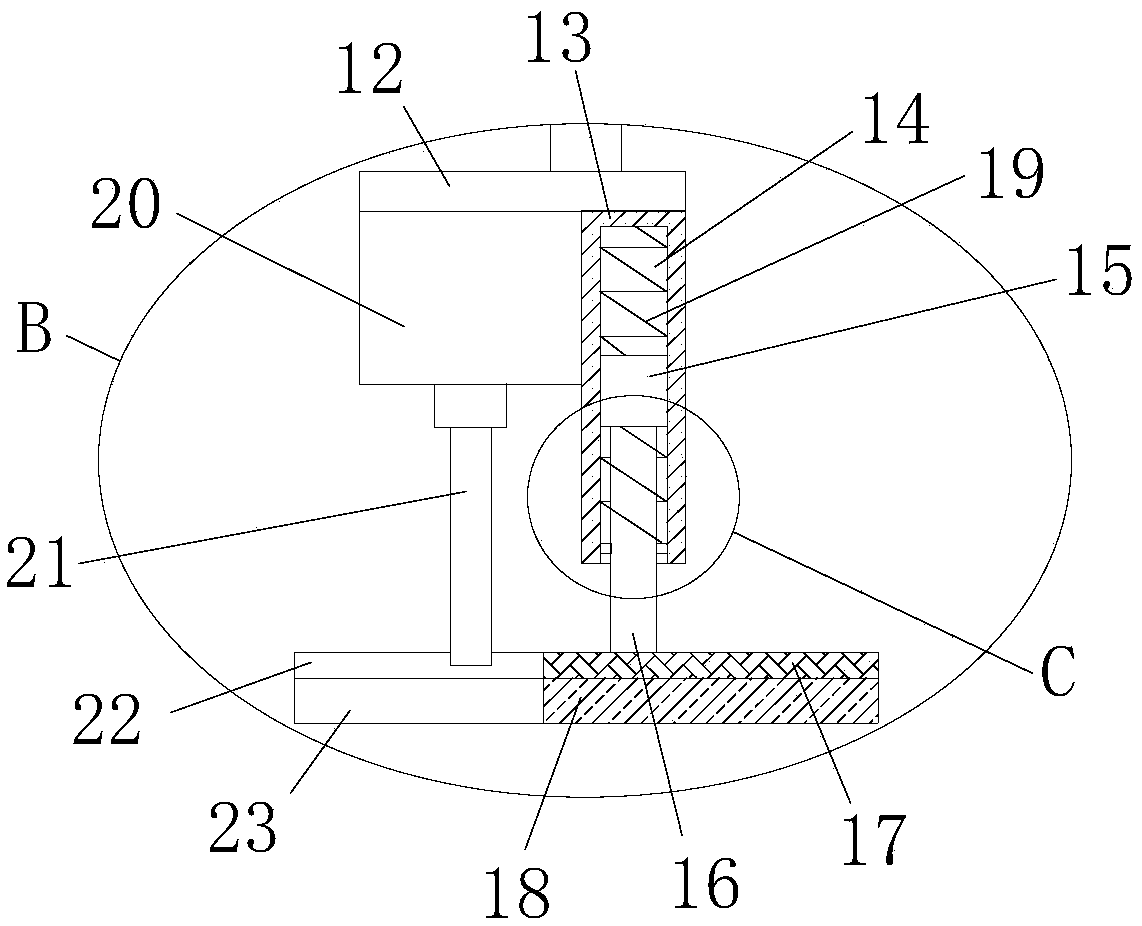

[0029] reference Figure 1-5 In this embodiment, a drilling system for a glass drilling machine is proposed, including a frame 1, a rectangular hole 2 is provided on the top side of the frame 1, and a plurality of glass conveying rollers 3 are rotatably installed on the inside of the rectangular hole 2. And the glass 4 to be drilled is placed on the plurality of glass conveying rollers 3, the four corners of the bottom of the frame 1 are all welded with supporting legs 26, and the side of the four supporting legs 26 close to each other is fixedly connected with the same supporting plate 5. The top of 5 is fixedly connected with a first hydraulic cylinder 6, the output shaft of the first hydraulic cylinder 6 extends into the rectangular hole 2 and is fixedly connected with a first support plate 7, and the top of the first support plate 7 is fixedly pasted with a first rubber pad 8. Two uprights 9 are welded on the top side of the frame 1, and the tops of the two uprights 9 are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com