Oxygen-inhaling type casting polypropylene semi-cooked film

A technology for casting polypropylene and polypropylene, applied in the field of plastic films, can solve the problems of increased oxygen concentration, oxygen residue, accidental ingestion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

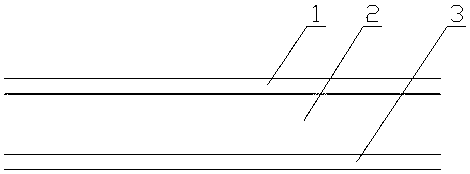

[0010] The specific embodiment of the present invention will be described below in conjunction with accompanying drawing, as figure 1 Shown: an oxygen-absorbing cast polypropylene semi-cooked film, characterized in that: the film is a three-layer structure, followed by an oxygen-absorbing layer 1, an intermediate layer 2 and a heat-sealing layer 3 from top to bottom, the above-mentioned The three-layer structure is prepared by co-extrusion casting process, in which the oxygen-absorbing layer 1 contains 20-60% random copolymerized polypropylene and 40-80% iron-containing oxygen-absorbing masterbatch, and the middle layer 2 contains 85-100% Random copolymerized polypropylene and 0-15% polyolefin elastomer, heat seal layer 3 contains 81-99.5% random copolymerized polypropylene, 0-15% polyolefin elastomer and 0.5-4% slip resistance Adhesion masterbatch, the above proportions are all percentages by mass, wherein the thickness of the oxygen absorbing layer 1 is greater than 20 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com