Turnover basket for edible fungus bags

A technology for revolving baskets and edible fungi, which is applied in the application, rigid container, mushroom cultivation and other directions, can solve the problems of unreasonable structure and unstable stacking of revolving baskets, and achieves the effect of simple structure and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

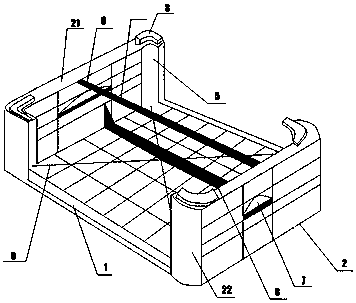

[0011] Combine below figure 1 The present invention is further described.

[0012] see figure 1 , a turnover basket for edible mushroom bags, comprising a base 1 and side walls 2, symmetrical side walls 2 are vertically connected to both sides of the base 1, the side walls 2 include side plates 21 and columns 22, side plates 21 The two sides are connected with vertical columns 22, the top of the column 22 is provided with a boss 3, the bottom of the column 22 is provided with a slot 4 matching with the boss 3, and the inner side of the column 22 is radially provided with an arc-shaped groove 5 .

[0013] The present invention only adopts the cooperation of the base 1 and the side wall 2, and the structure is simple. The side wall 2 is composed of a side plate 21 and a column 22 . The fixed beams 6 are connected between the side walls 2, and the cross-fixed reinforcing ribs 9 are arranged on the base 1, so that this design ensures the stability of the entire basket on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com