A tension adjusting device for textile fiber winding

A tension adjusting device and the technology of the adjusting device, which are applied in the field of textile processing, can solve the problems of inconvenient maintenance and complicated circuits, and achieve the effects of avoiding breakage, avoiding jamming, and avoiding breakage of textile fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

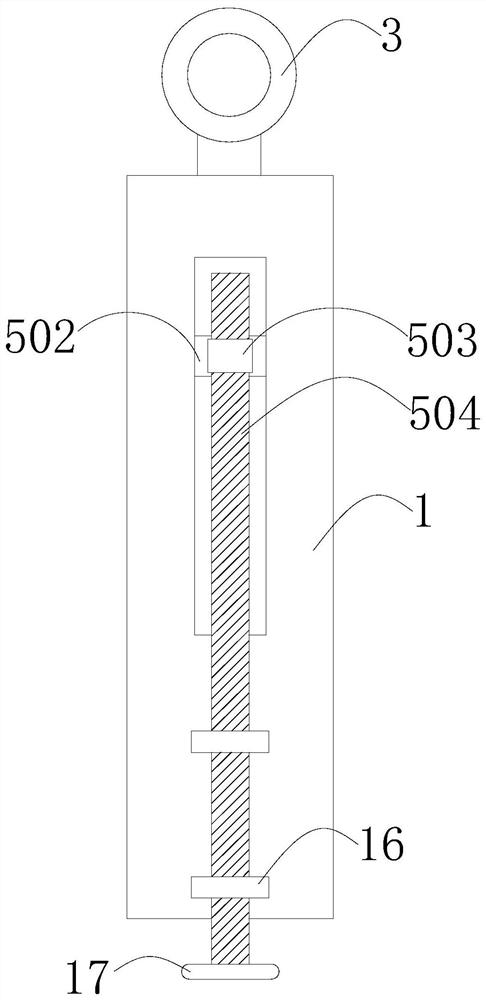

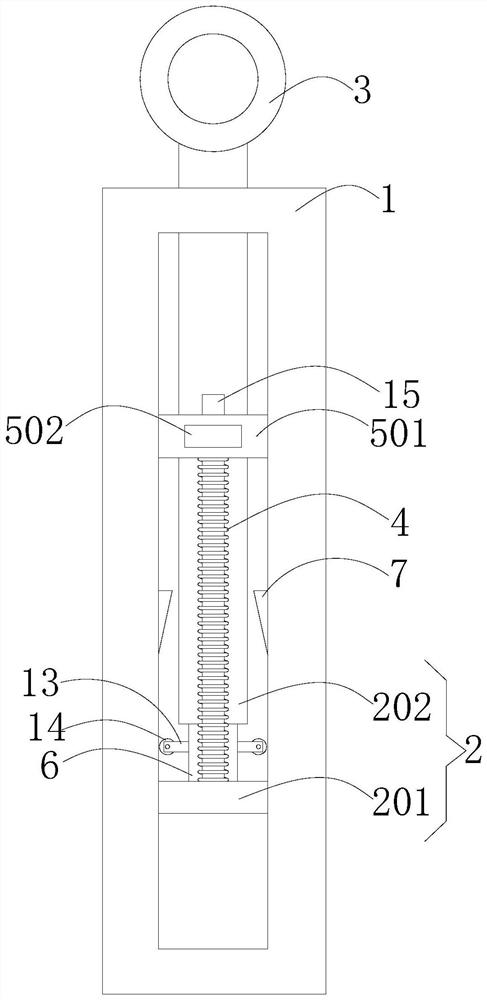

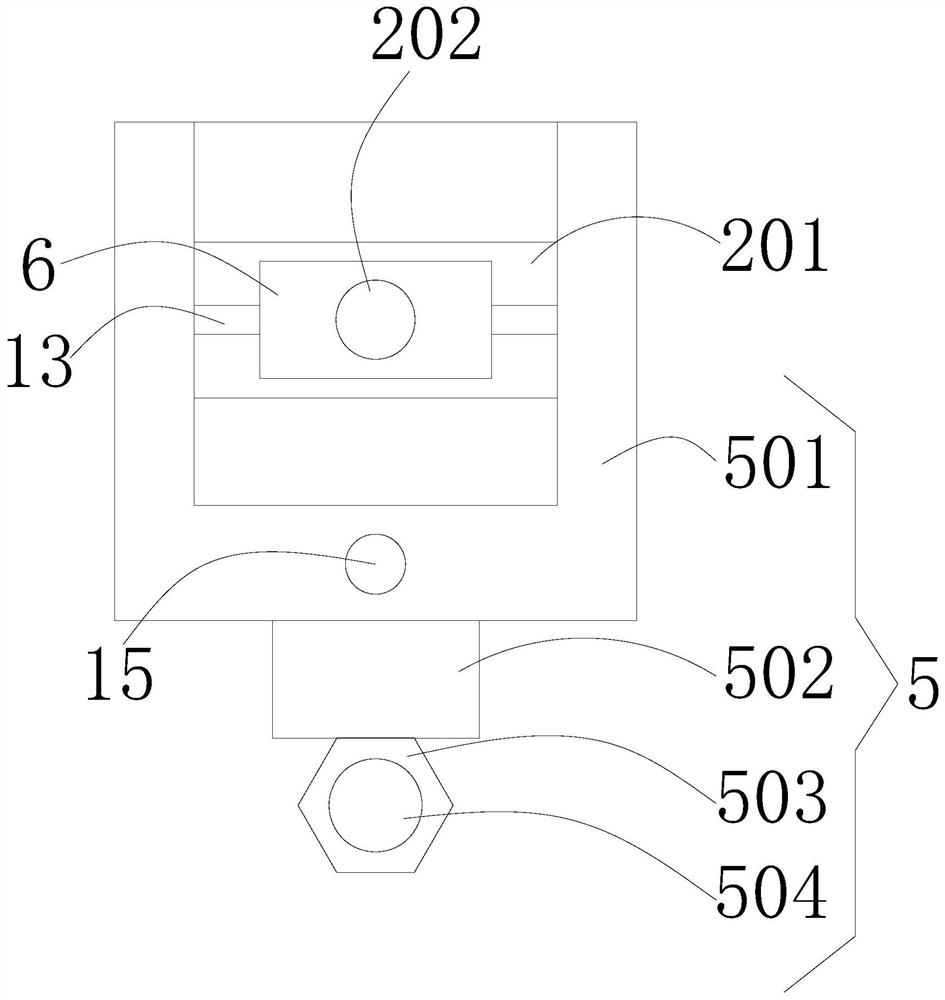

[0026] Such as Figure 1-4 As shown, the embodiment of the present invention provides a tension adjustment device for textile fiber winding, including an adjustment device body 1, a pull ring 3, an elastic element 4, and a limit mechanism 5. The inside of the adjustment device body 1 is hollow, and the adjustment device The inside of the main body 1 is slidingly installed with a liftable lifting mechanism 2, the output end of the lifting mechanism 2 passes through the adjusting device body 1 and is fixed with the pull ring 3, the limit mechanism 5 is arranged inside the adjusting device body 1, and the elastic element 4 It is arranged between the limit mechanism 5 and the lifting block 201 of the lifting mechanism 2 . The elastic element 4 is a spring, and a sliding rod 15 is fixed on the top of the lifting block 201 , the sliding rod 15 passes through the baffle 501 and is slidably connected with the baffle 501 .

[0027] Wherein the limit mechanism 5 includes a baffle plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com