Efficient express item conveying system

A conveying system and high-efficiency technology, used in transportation and packaging, elevators and elevators in buildings, etc., can solve the problem of increasing elevator utilization frequency and utilization time, increasing elevator waiting time for office workers, and ignoring the huge burden of elevator systems, etc. It can save the time of office staff, save the time of waiting for the elevator, and save the time of receiving the mail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

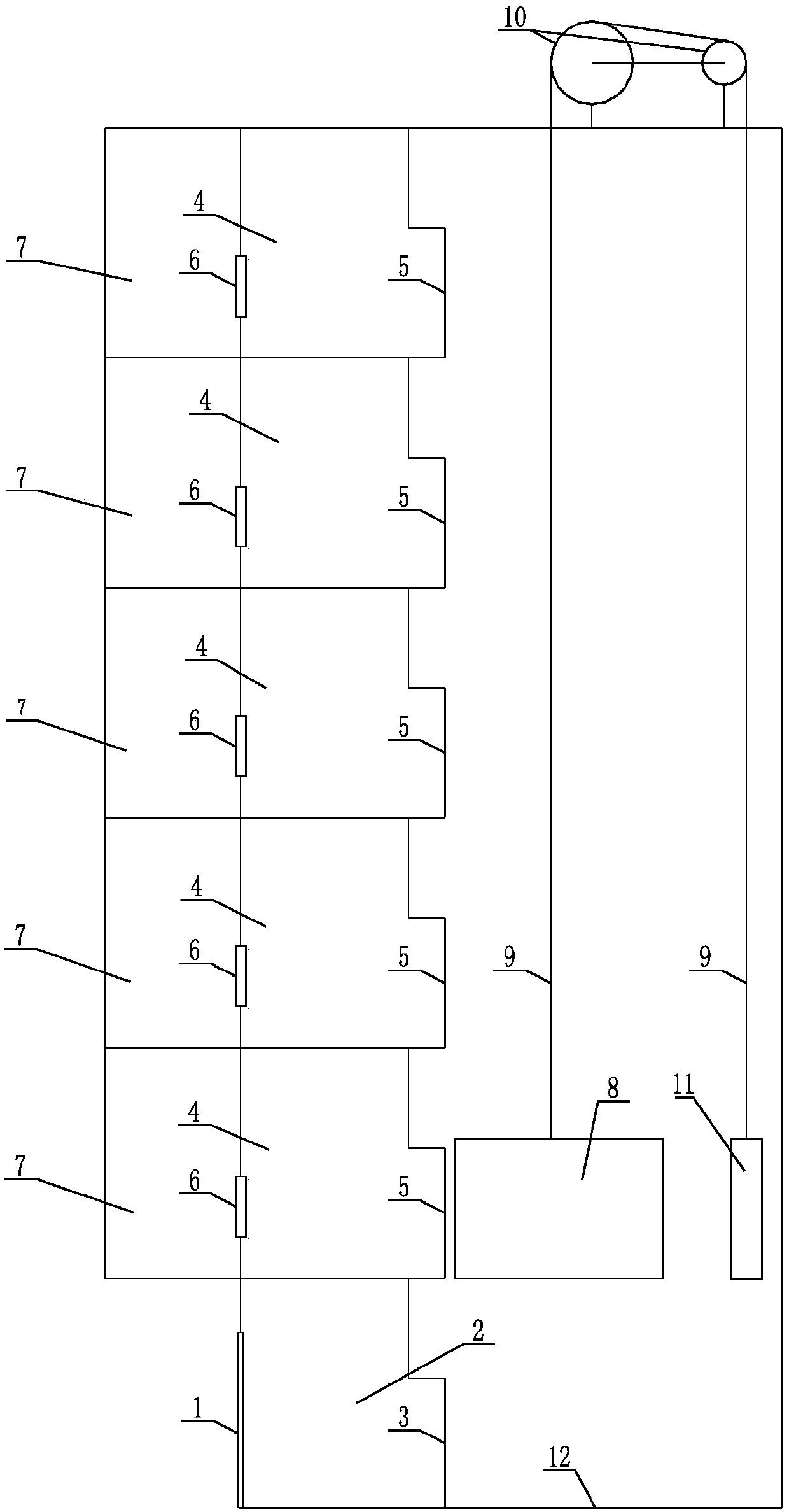

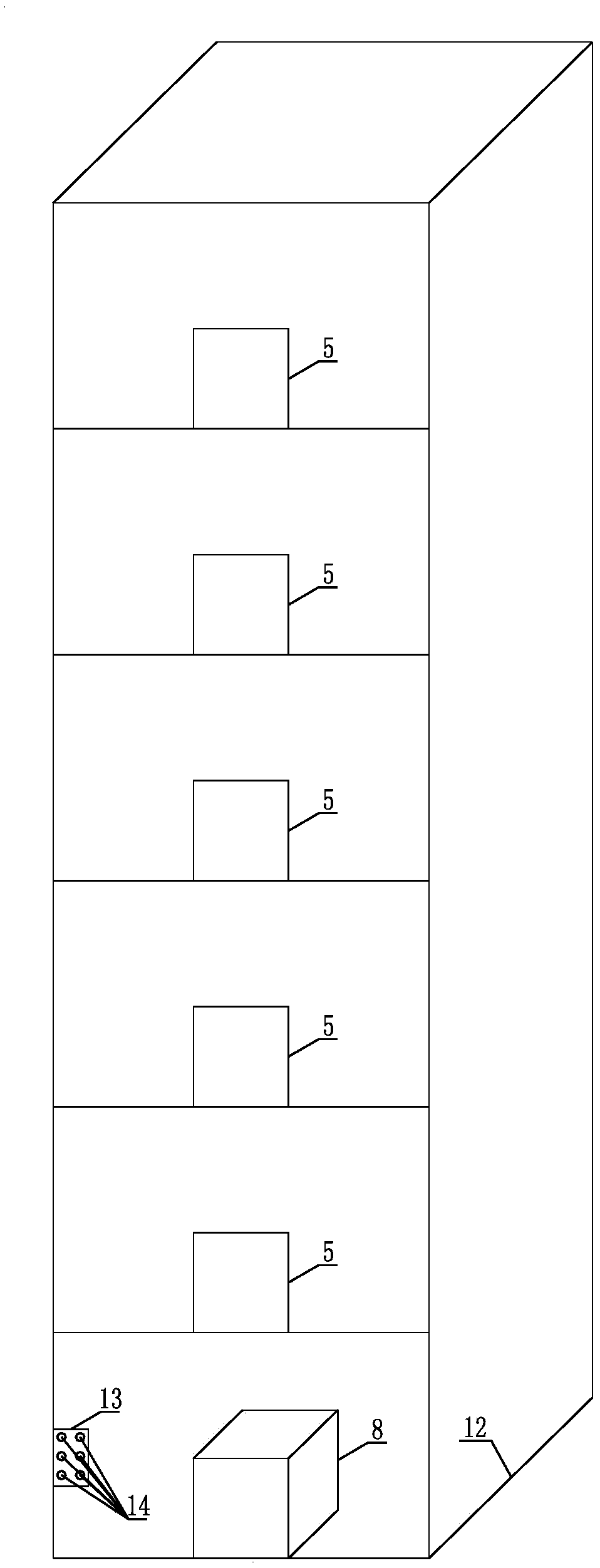

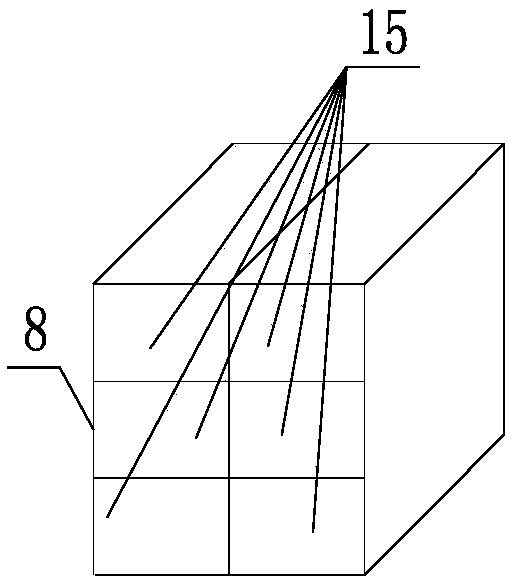

[0023] see Figure 1 to Figure 6 , a high-efficiency express delivery system, including a controller 13, an express delivery hall 2, a delivery shaft 12, and an express receiving warehouse 4 connected to the elevator front room 7 on the second floor and above floors. The express delivery hall 2 is connected to the delivery well 12 through the delivery door 3, a delivery bin 8 and a counterweight 11 are arranged in the delivery well 12, and a traction mechanism 10 is installed on the top of the delivery well 12, The traction mechanism 10 is transmission-connected with the delivery bin 8 and the counterweight 11 through a traction rope 9; There is a warehouse door 16, and the rear end is provided with an unloader 17, wherein N is the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com