Dust removal sanitary ware sintering device

A technology for sintering device and sanitary ware, which is applied in the direction of descaling device, charge composition/state, charging treatment type, etc., to achieve the effect of improving service life, simple structure and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

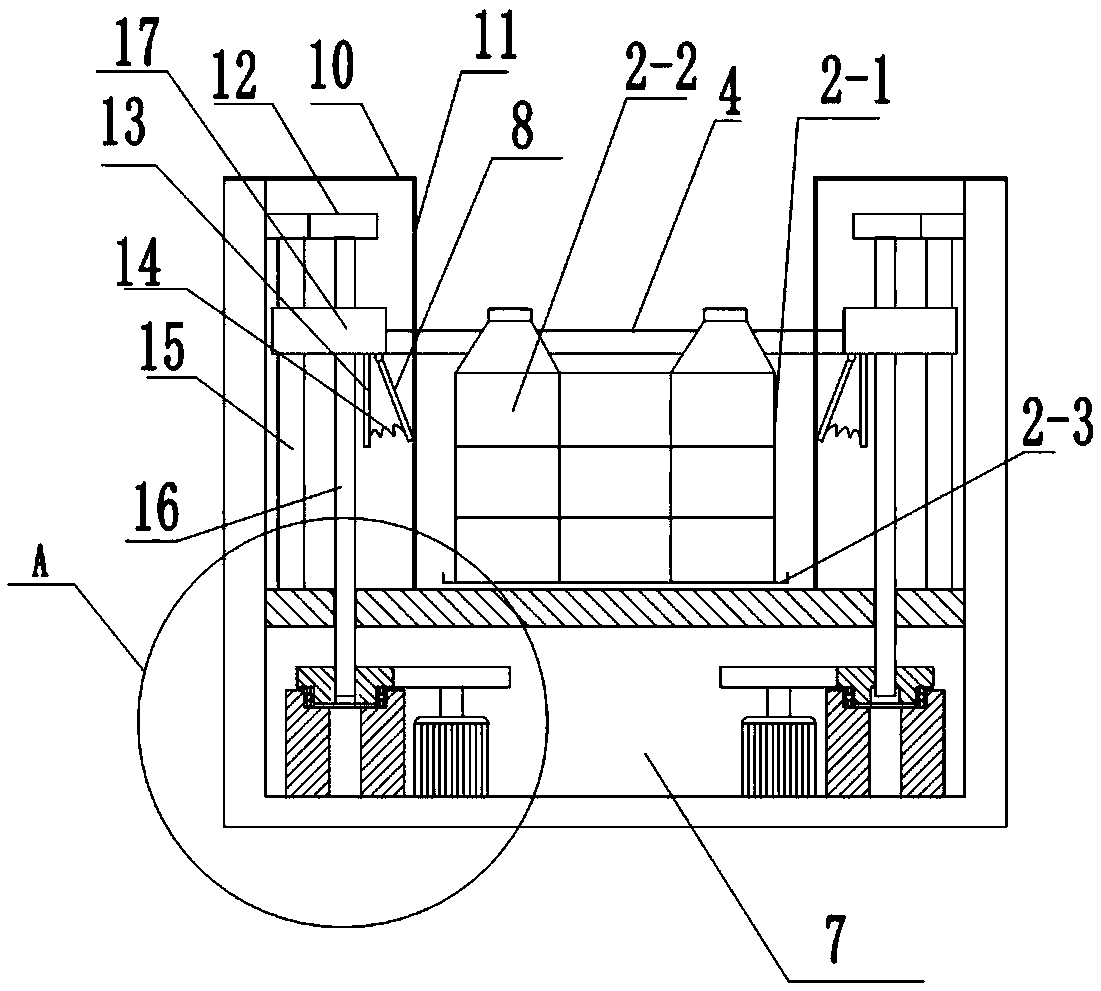

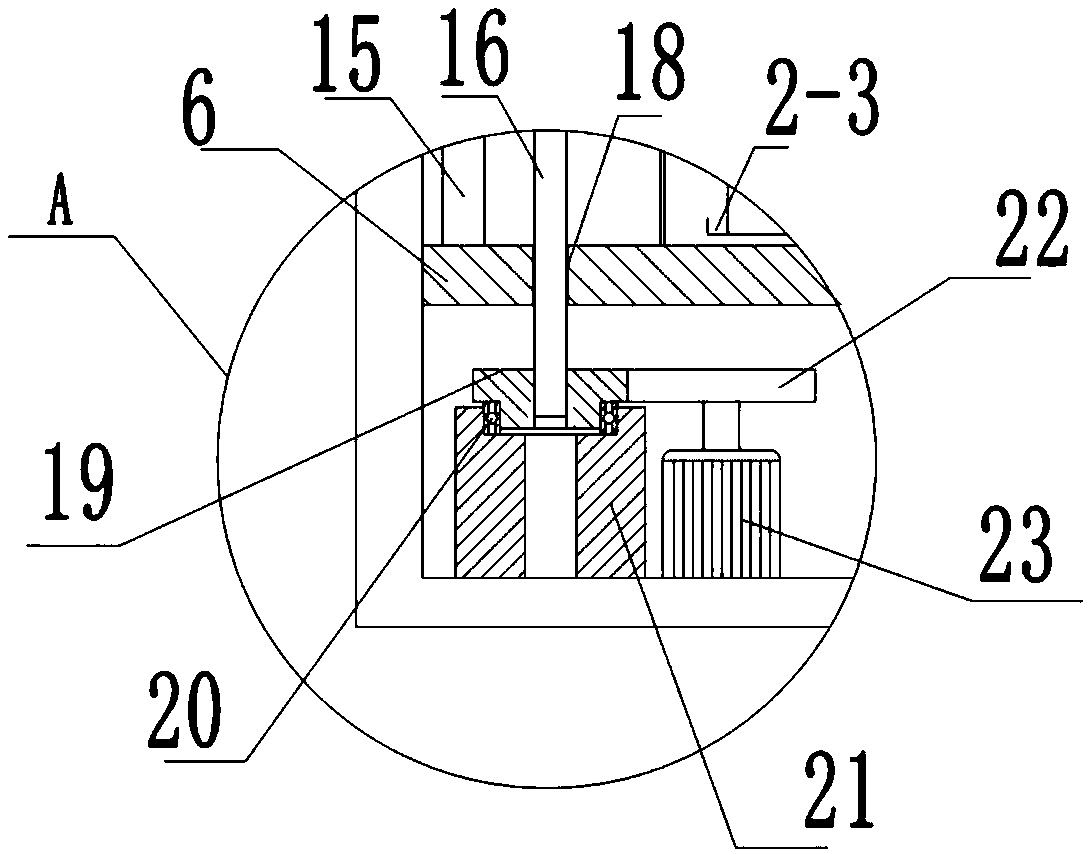

[0031] On the basis of Embodiment 1, the ceramic placement box 2 includes a ceramic placement cavity 2-2 provided inside and a side wall 2-1 that needs to be deashed, and is arranged on the side wall outside the lower part of the side wall 2-1 that needs to be deashed. There is an ash collecting tank 2-3; an observation port 2-4 is also provided on the side wall 2-1 that needs to be ash removed. A downwardly protruding arc portion 8-1 is provided at the lower end of the scraper plate 8, and a scraper 8-2 is provided upwardly on the protruding arc portion 8-1. When the scraper plate moves downward, the raised arc portion 8-1 can bypass the deposited dust with high resistance, thus ensuring the safety of the scraper.

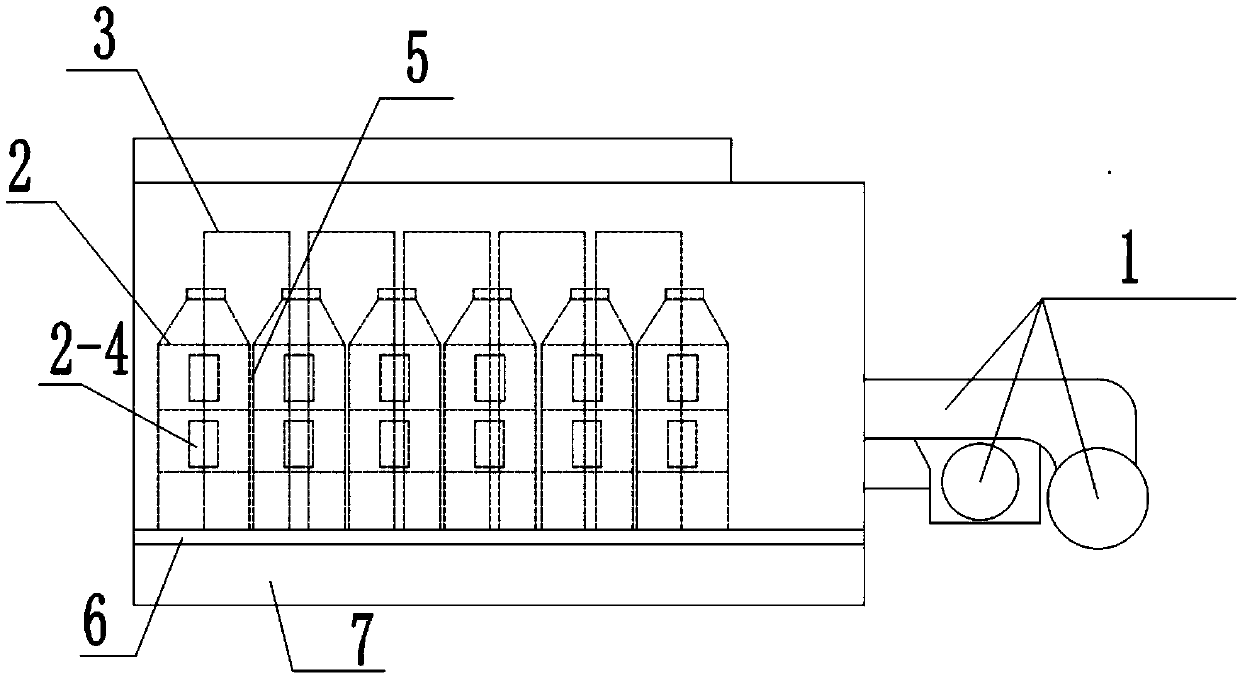

[0032] A gap 5 is provided between the adjacent ceramic placement boxes 2, and the transmission devices on both sides of the ceramic placement box 2 are connected through the middle scraper 4, and the middle scraper 4 passes through the gap 5, and the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com