A small and medium-sized garbage incinerator

A garbage incinerator, small and medium-sized technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of complex garbage composition, low combustion rate, insufficient combustion, etc., and achieve good incineration effect, complete combustion, and complete incineration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

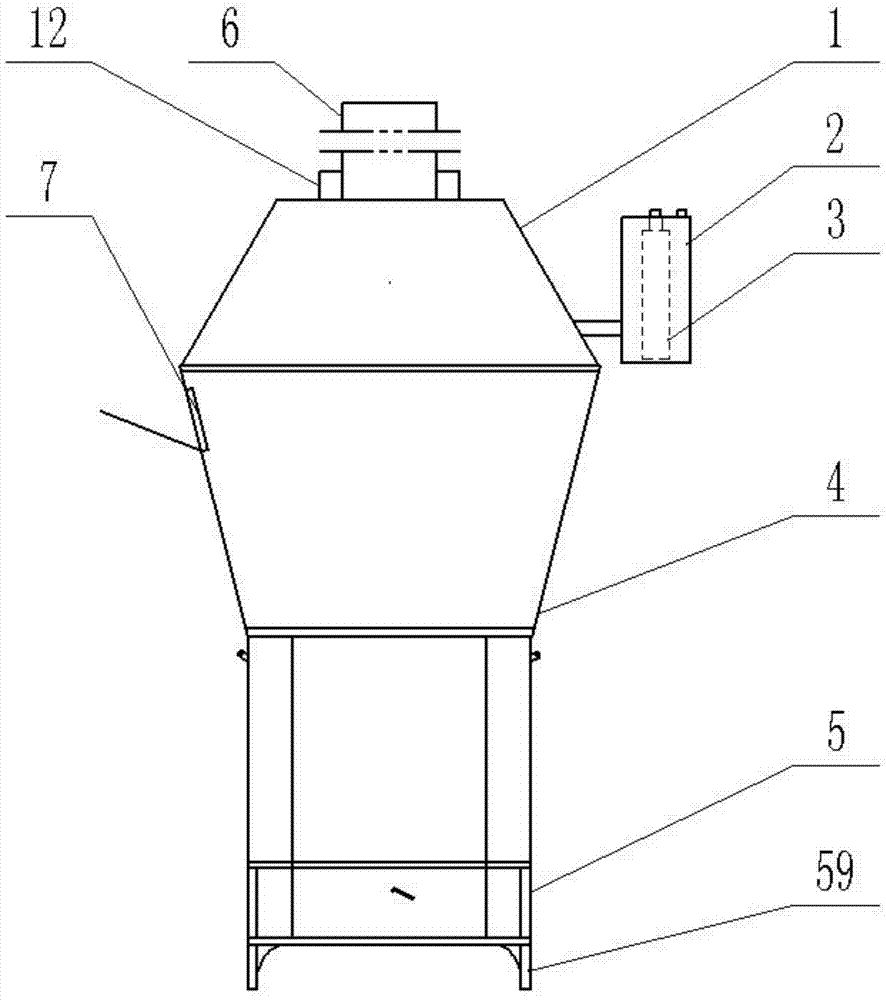

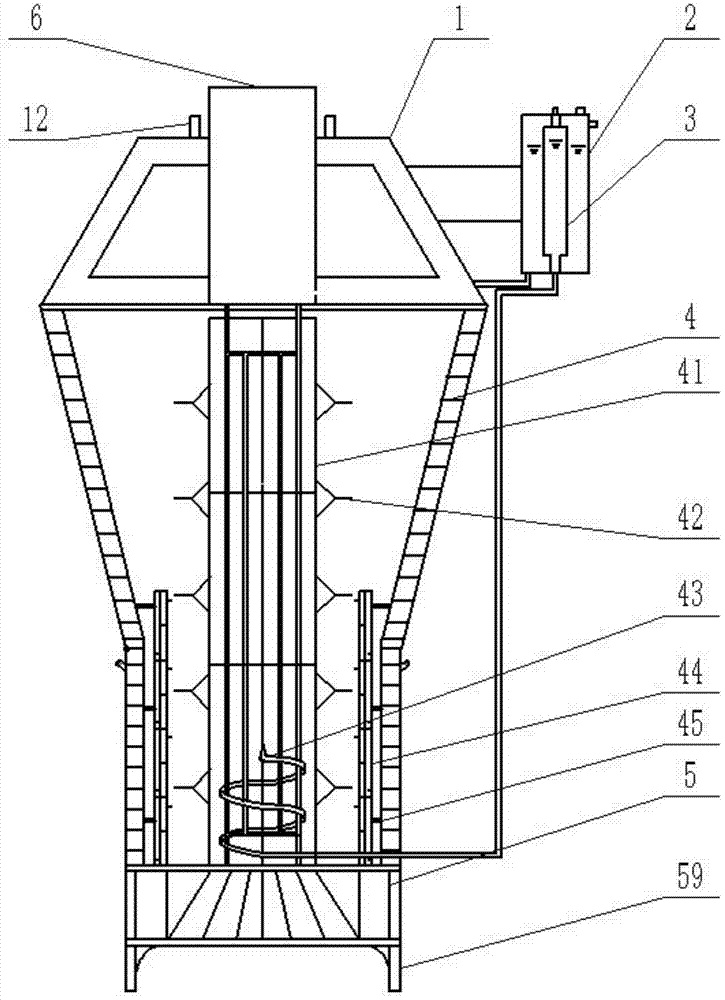

[0033] A small and medium-sized garbage incinerator comprises a furnace body 4 , an inner chimney 41 , a furnace cover 1 , an outer chimney 6 and a base 5 . Inner chimney 41 is located in the middle of body of heater 4, and body of heater 4 and inner chimney 41 constitute combustion chamber, and body of heater 4 is provided with refractory brick around. A furnace cover 1 is arranged above the furnace body 4 , and an outer chimney 6 is arranged on the top of the furnace cover 1 . The side wall above the body of furnace 4 is provided with a feeding port 7 , the lower end of the body of furnace 4 and the base 5 . The outside of the furnace cover 1 is provided with a water tank 2, and the water tank 2 is also provided with an oil tank 3; the inner chimney 41 is provided with a gasification coil 43, and the gasification coil 43 is connected to the oil tank 3 through an oil pipe .

[0034] The inner chimney 41 is in the shape of a long cage, which is welded at a certain distance f...

Embodiment 2

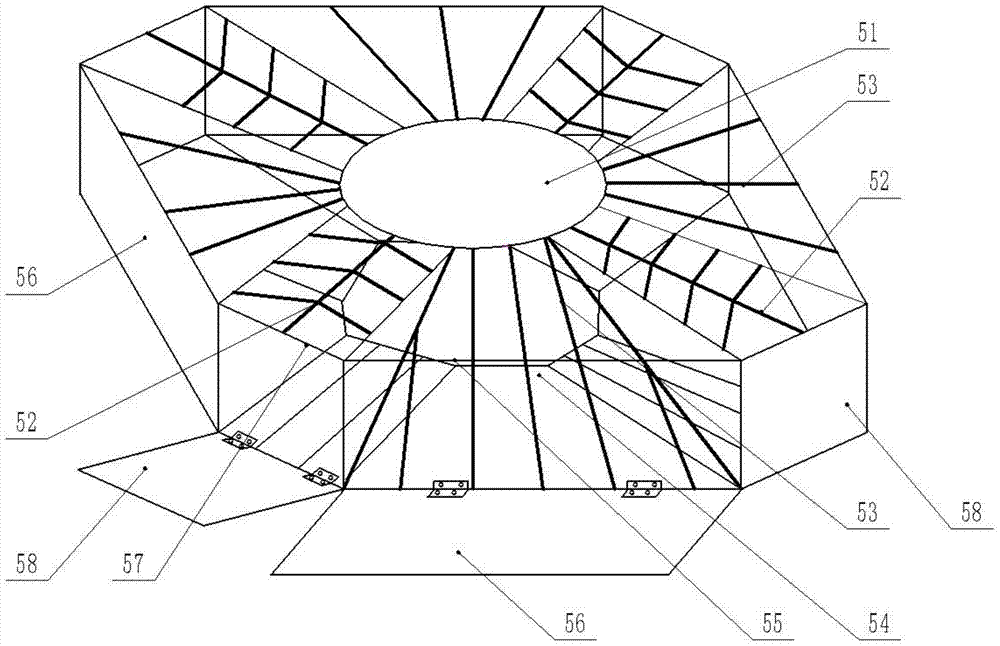

[0038]The difference from Example 1 is that the base 5 is provided with a furnace bridge, a furnace foot 59 and a bottom plate 54, a fixed furnace foot 59 is arranged under the base 5, and a slag discharge port 55 and an ignition port 57 are opened around the base 5. The slag opening 55 is adjacent to the ignition opening 57, and each slag discharge opening 55 and ignition opening 57 is provided with a slag discharge door 56 and an ignition door 58 correspondingly. The middle part of the base 5 is also provided with a chimney air inlet 51 , and the inner chimney 41 is fixed above the chimney air inlet 51 . The furnace bridge is composed of an inclined furnace bridge 53 and a ∧-shaped furnace bridge 52; the inclined furnace bridge 53 is welded by a plurality of inclined steel bars at a certain distance, and one end of the inclined furnace bridge 53 is hingedly installed on the chimney inlet 51 , the other end is fixed at the slag outlet 55 by a push rod; the ∧-shaped furnace br...

Embodiment 3

[0041] The difference from Example 1 is that the furnace body 4 also includes a square cage 44, a corner cage and a fixed rod 45; the square cage 44 and the corner cage are respectively alternated by a plurality of vertical steel bars and transverse steel bar rings. Welded at a certain distance. Described corner cage is located in four angles of square cage 44, and is provided with hook outside corner cage and square cage 44 insides;

[0042] The square cage 44 and the corner cage of this embodiment support the rubbish, and prevent the rubbish from accumulating at the corners of the body of heater simultaneously, so that the air around the body of heater is sufficient, and the rubbish has no dead corners, which improves the combustion efficiency of the rubbish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com