A test device for a quasi-zero stiffness vibration isolator

A technology of quasi-zero stiffness and test device, which is applied in the field of vibration response test of vibration isolators, can solve the problems of inconvenient replacement of device components, cumbersome device structure, inflexible adjustment of device stiffness range, etc., to solve the problem of large volume and flexible installation with the effect of uninstalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

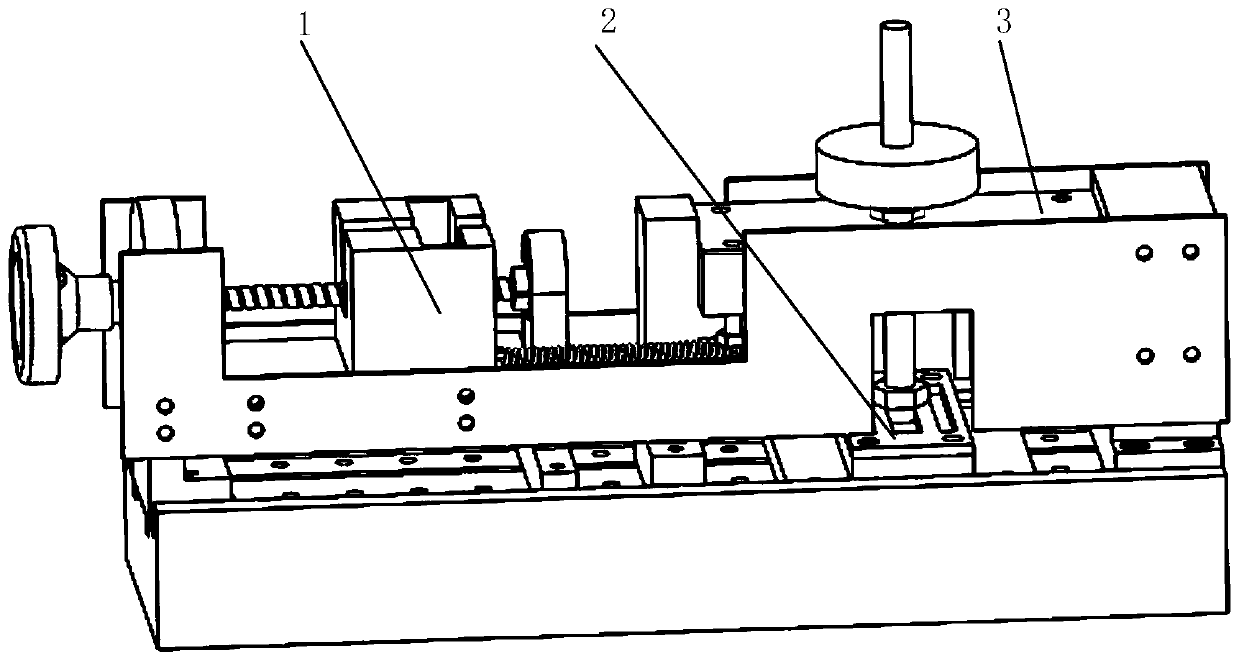

[0031] Such as figure 1 As shown, the overall structure of a test device for a quasi-zero stiffness vibration isolator according to the present invention includes a negative stiffness adjustment mechanism 1 , a positive stiffness adjustment mechanism 2 , and a beam-damping block mechanism 3 .

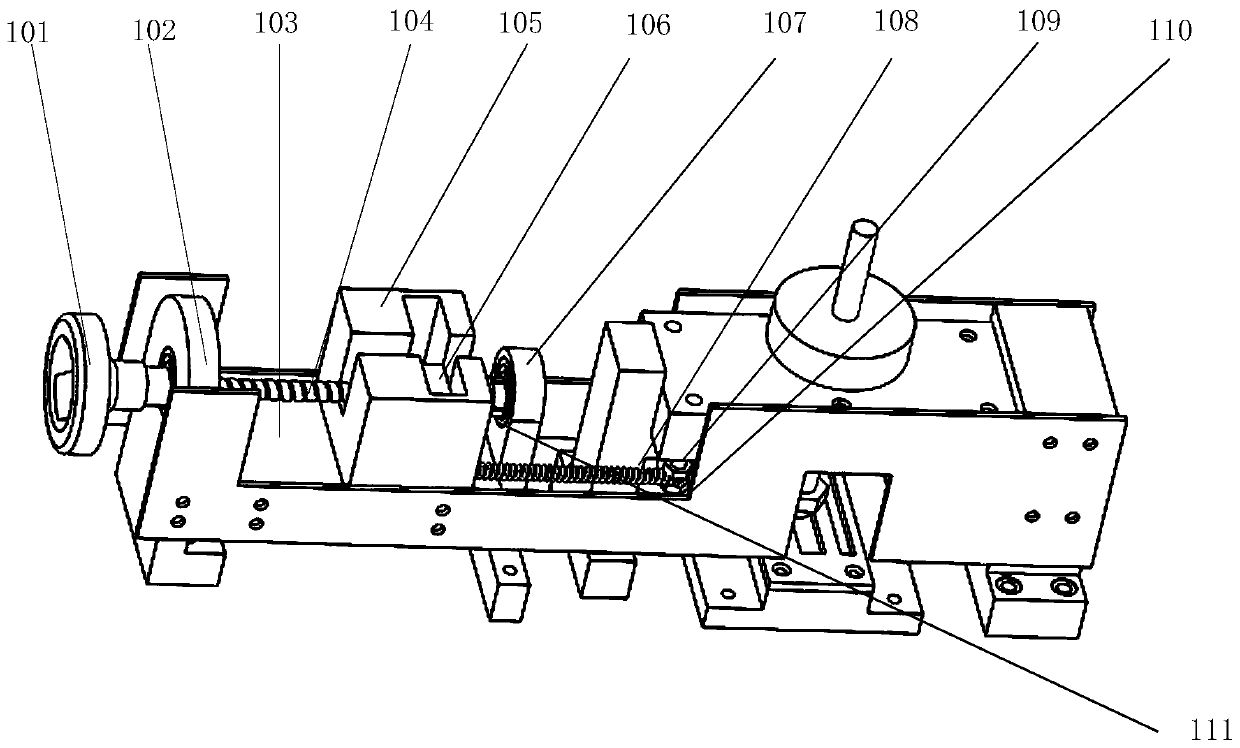

[0032] Such as figure 2 As shown, the negative stiffness adjustment mechanism 1 is used to adjust the negative stiffness value of the system; the negative stiffness adjustment mechanism includes a screw hand wheel 101, a bearing seat A102, a bottom support plate 103, a lead screw 104, and a moving actuator 105 , lead screw slider 106, bearing seat B107, spring 108, bolt 109, nut 110, deep groove ball bearing 111; the bottom support plate 103 is connected with bearing seat A102 and bearing seat B107 by screws; bearing seat A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com