High-precision probe clamping device for sampling positioning in neutron diffraction measurement

A technology for sample positioning and clamping device, applied in measurement devices, material analysis using wave/particle radiation, and force measurement, etc., can solve problems such as easy deformation and breakage, waste of neutron beam time, and increased preparation time, etc. Achieve the effect of improving positioning accuracy, improving efficiency and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

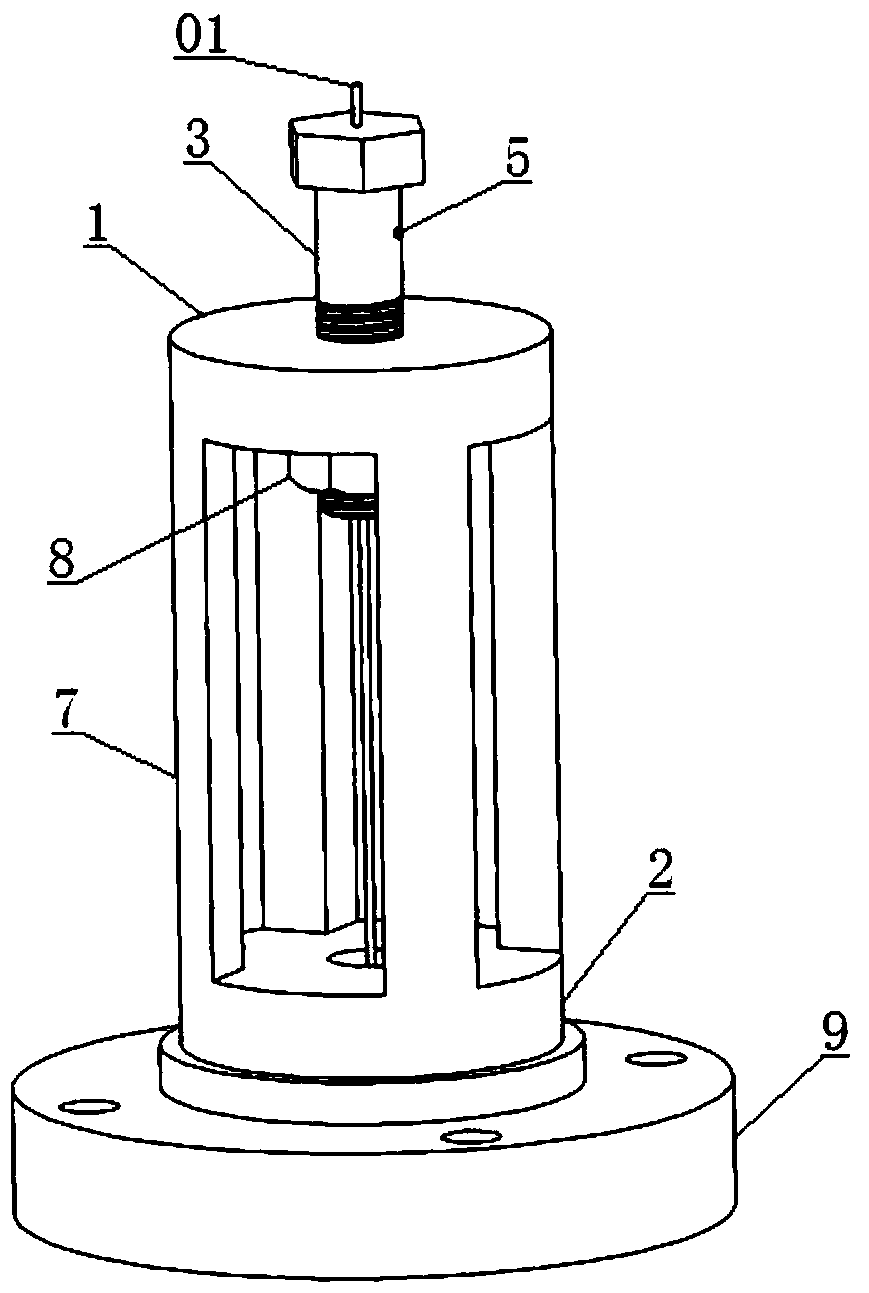

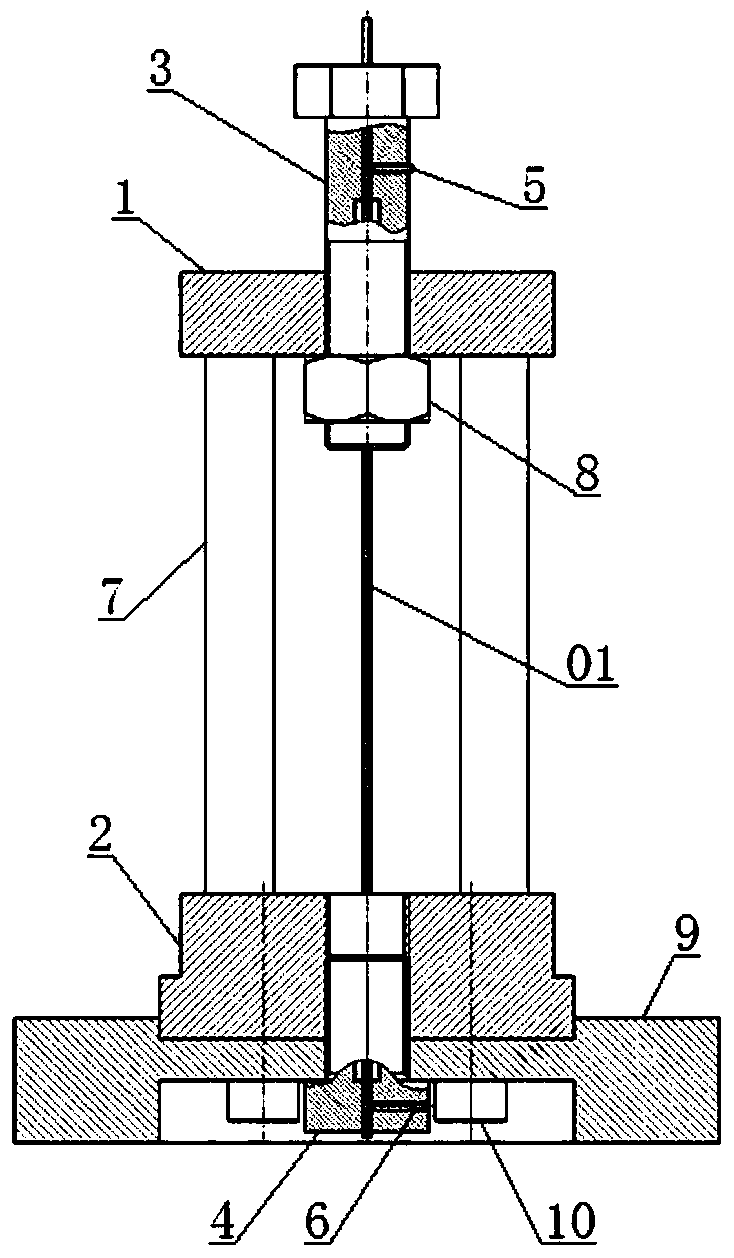

[0036] see figure 1 and figure 2 , a high-precision probe clamping device for sample positioning in neutron diffraction measurement, including a top plate 1, a base 2, an upper positioning member 3, a lower positioning member 4, an upper fastening screw 5, a lower fastening screw 6 and Attach chassis 9.

[0037] The base 2 is arranged at the central position of the connecting chassis 9 and the two are fixedly connected by interference fit and connecting screws 10, and a plurality of screws are arranged on the connecting chassis 9 to realize the fixing between it and the sample stage 02. connected bolt connection holes, the top plate 1 is arranged directly above the base 2 and a vertical support connecting column 7 is arranged between them, and the upper positioning member 3 and the lower positioning member 4 are respectively arranged on the top plate 1 and the base 2 and the distance between the two positioning pieces in the vertical direction is adjustable, and the center ...

Embodiment 2

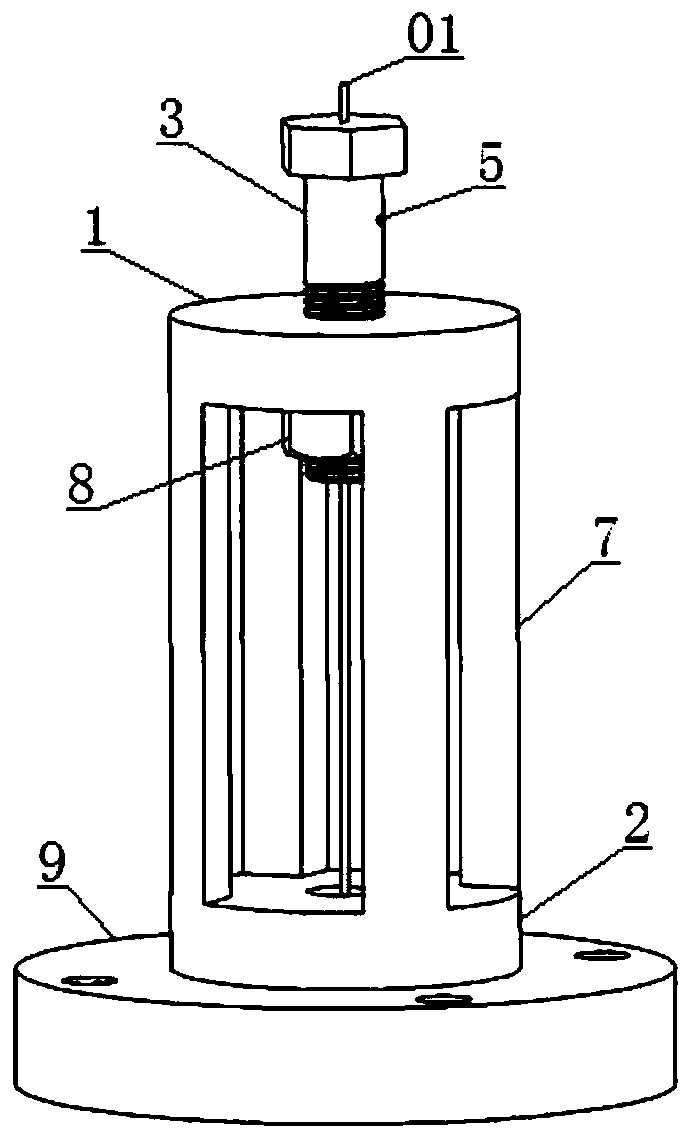

[0041] see image 3 and Figure 4 , a high-precision probe clamping device for sample positioning in neutron diffraction measurement, except that the connecting screw 10 is eliminated between the base 2 and the connecting chassis 9 and the integral molding method is adopted, the other structures are exactly the same as in Example 1 .

Embodiment 3

[0043] see Figure 5 and Figure 6 , a high-precision probe clamping device used for sample positioning in neutron diffraction measurement, its structure is basically the same as that of Embodiment 1, the differences are as follows: In this embodiment, the supporting connecting column 7 and the top plate 1 and the base 2 are connected in a detachable manner, specifically, the two ends of the supporting connecting column 7 are designed in the form of bolts and are respectively fixedly connected to the top plate 1 and the base 2 through matching nuts or threaded holes; The example does not include the connection chassis 9, so there is no need for connection screws 10, the base 2 is directly fixed on the sample stage 02 of the neutron diffraction spectrometer and is provided with a plurality of bolt connection holes on the base 2; in this embodiment, The threaded ends of the two locating parts are set downwards, and matching gaskets and adjusting nuts 8 are provided on the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com