A high-efficiency conductive silver glue bonding wire sealing process for semiconductors

A technology of conductive silver glue and glue sealing process, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, circuits, etc., can solve the problems of time-consuming, reduce the qualified rate of finished products, and occupy manpower and man-hours, so as to speed up curing time and improve processing Efficiency and the effect of reducing labor occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

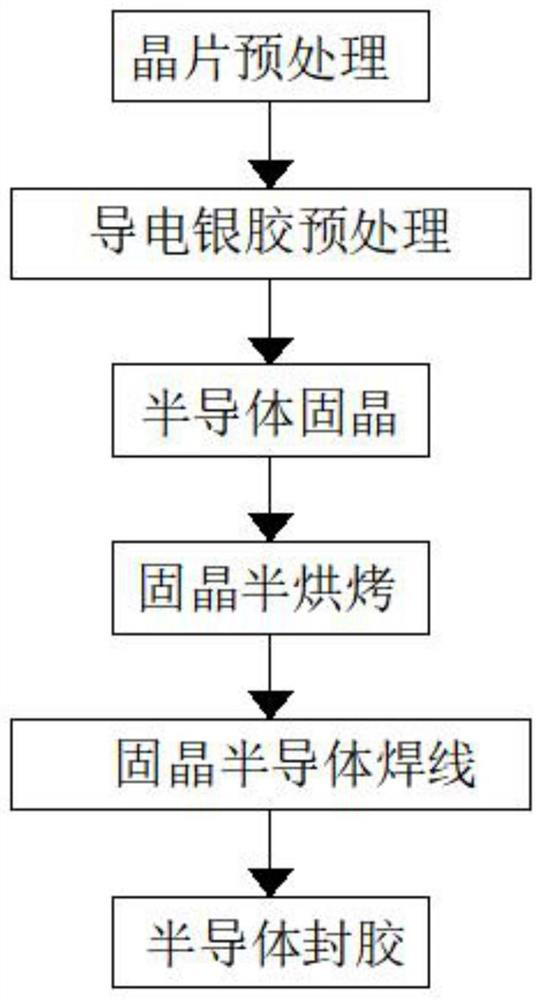

[0041] see figure 1 , a semiconductor high-efficiency conductive silver glue die-bonding wire sealing process, comprising the following steps:

[0042] Step 1: Chip pretreatment. After confirming the raw material specifications and batches after the warehouse feeds, the original chip is torn off the film. After the film is peeled off, the original chip is expanded. After the expansion is completed, the chip to be processed is obtained. , Step 1 During the chip pretreatment process, open the upper cover of the crystal expander, and place the inner ring of the crystal expander on the base flatly, with the smooth side facing up. The technicians tear off the centrifuge paper of the chip, with the centrifuge paper facing up and the blue film facing down. , to facilitate the complete expansion and deployment of the chip. In the pretreatment process of step 2 conductive silver glue, first thaw the bottle and syringe. The thawing time is 30 minutes. After thawing is completed, move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com