Grass carp static farming food provisioning apparatus with function of enlarging food provisioning areas by means of pressurization

A supercharger and grass carp technology, applied in application, fish farming, climate change adaptation, etc., can solve problems such as spoilage of water quality, fast feeding speed, waste, etc., to expand feeding area, reduce feed cost, and guarantee The effect of healthy growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be further clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

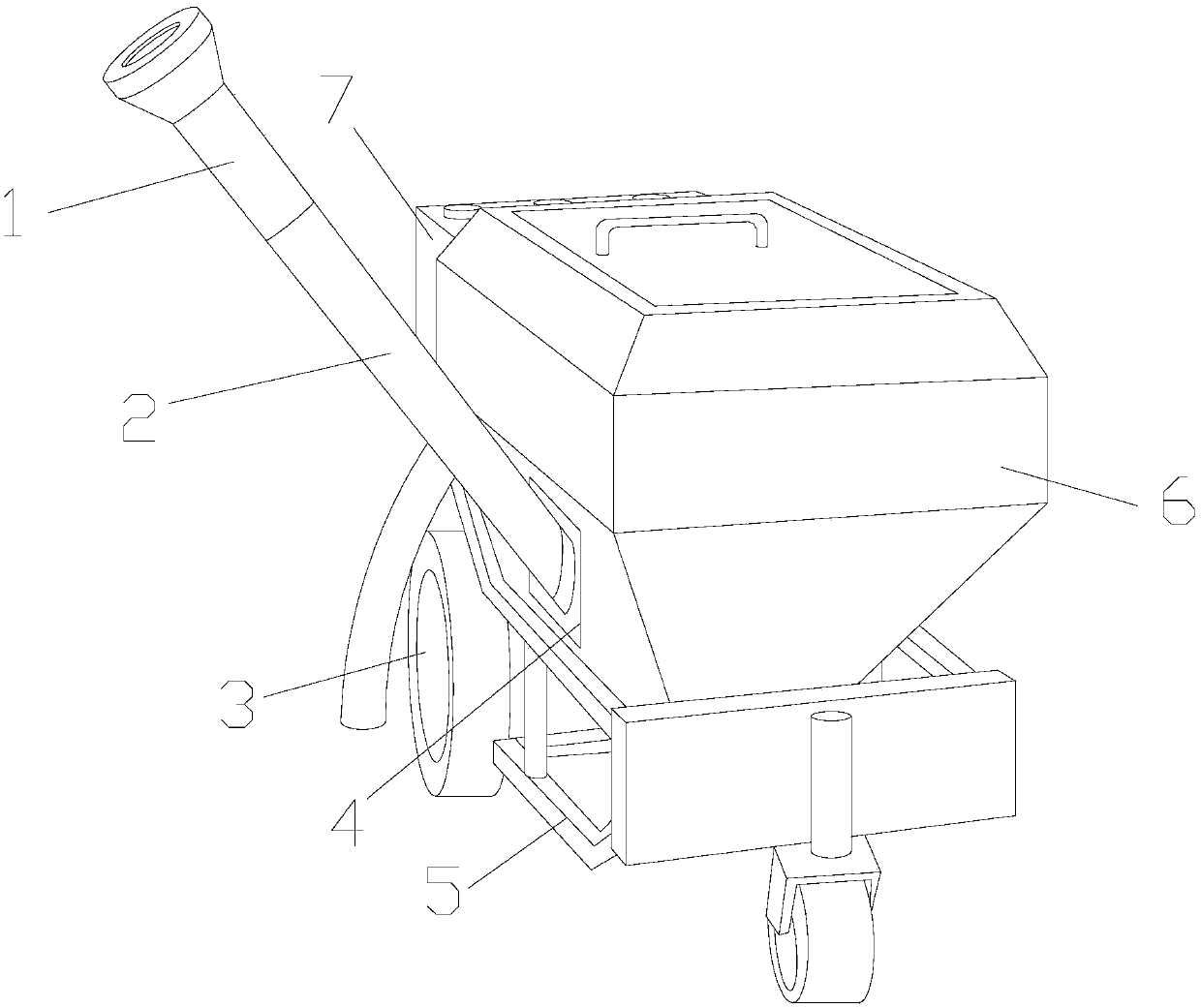

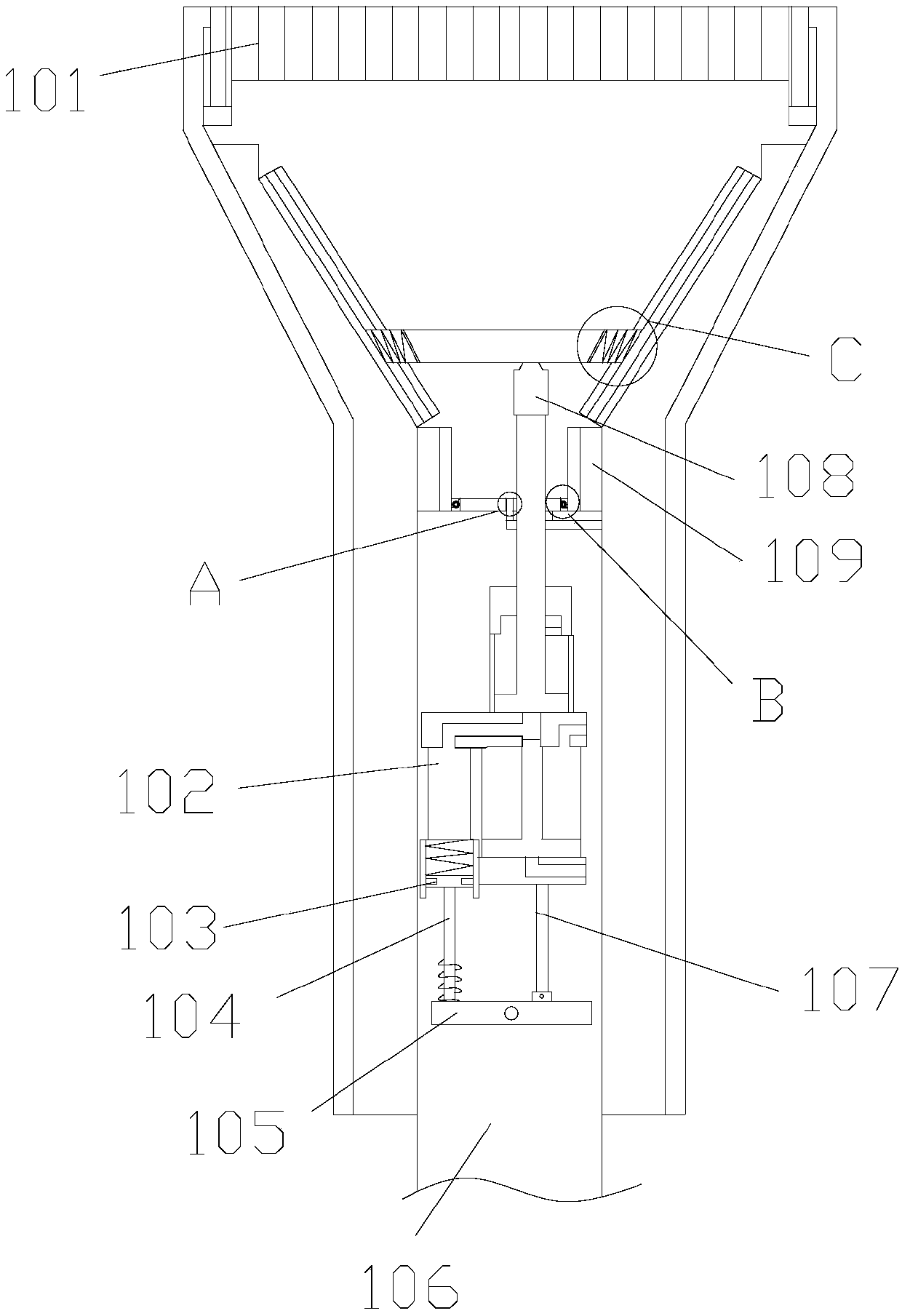

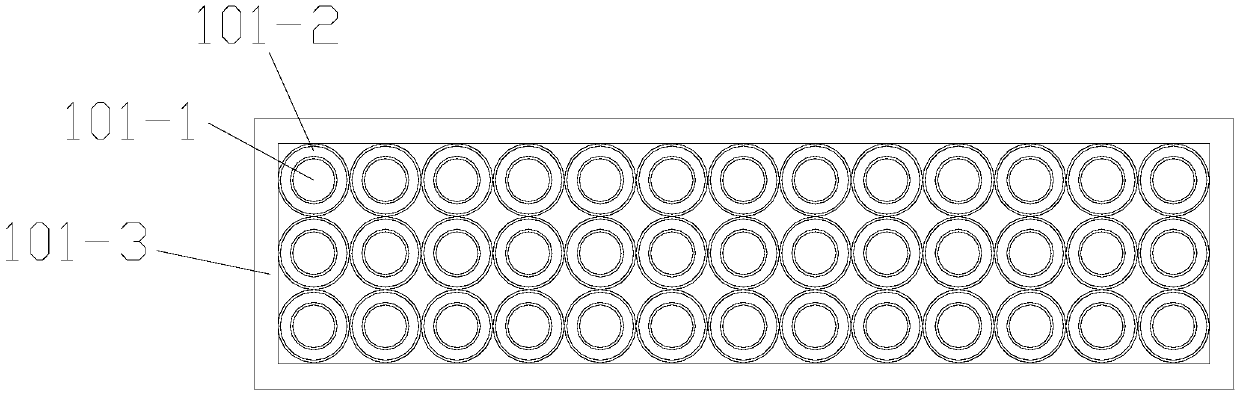

[0029] see Figure 1-Figure 7 , the present invention provides a grass carp feeder that adopts pressurization to expand the feeding area: its structure includes a feeding head 1, a feeding tube 2, a wheel 3, a lifter 4, a support 5, a food storage box 6, a controller 7, It is characterized by:

[0030] The feeding head 1 is fixedly installed on the front end of the feeding tube 2 and is an integrated structure, the end of the feeding tube 2 is welded to the lifter 4, and the wheels 3 are provided with three and arranged on the front and rear sides of the bracket 5 to move with it Connected, the lifter 4 is embedded in the lower end of the left side of the food storage box 6, the support 5 is welded to the bottom of the food storage box 6, and the controller 7 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com