Automatic frying pan constant-power control method, automatic frying pan constant-power control device and automatic frying pan

A technology of constant power control and cooking pot, applied in heating devices, control/adjustment systems, instruments, etc., can solve the problems of undercooked cooking, position shift of pots, power conversion of pots, etc., so as to ensure the effect of cooking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

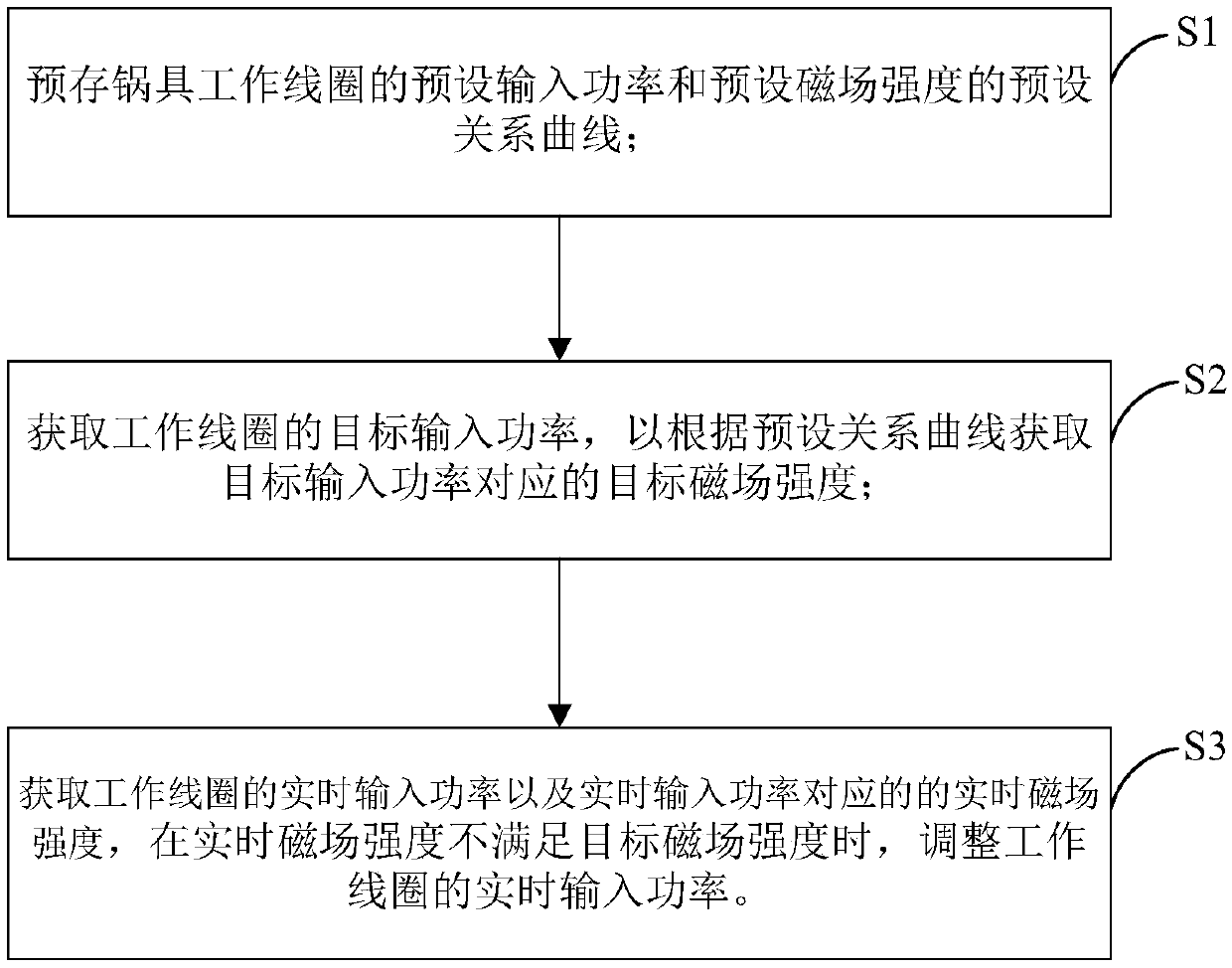

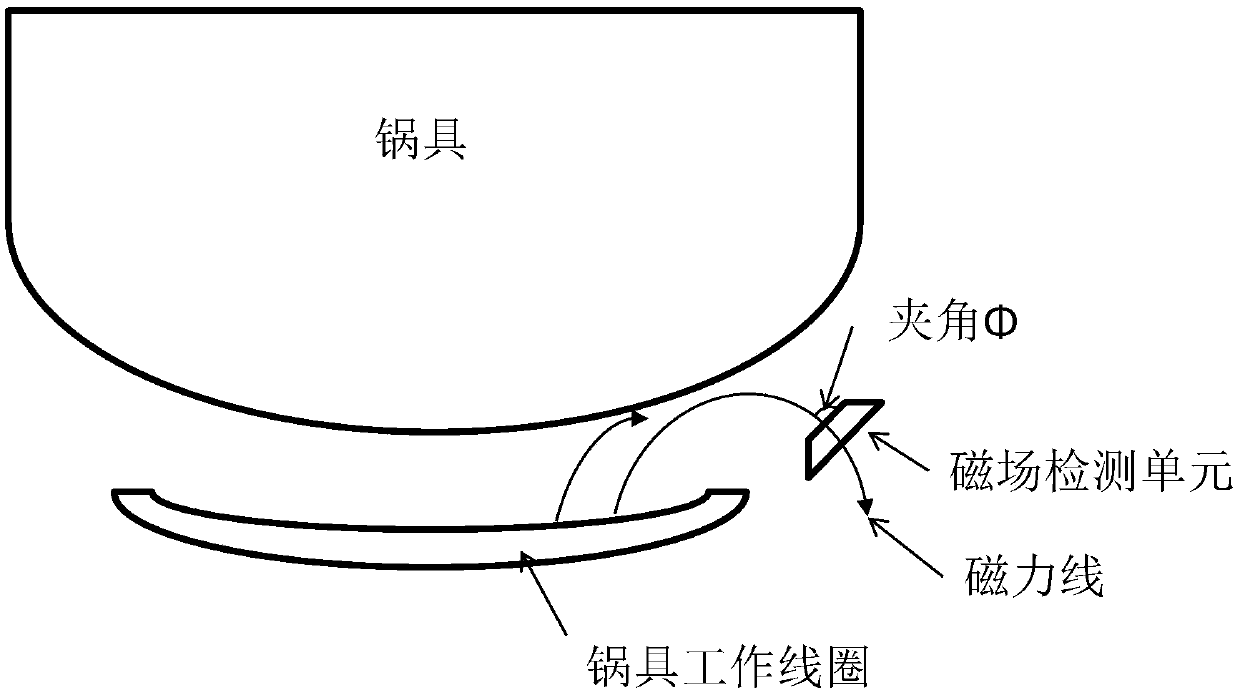

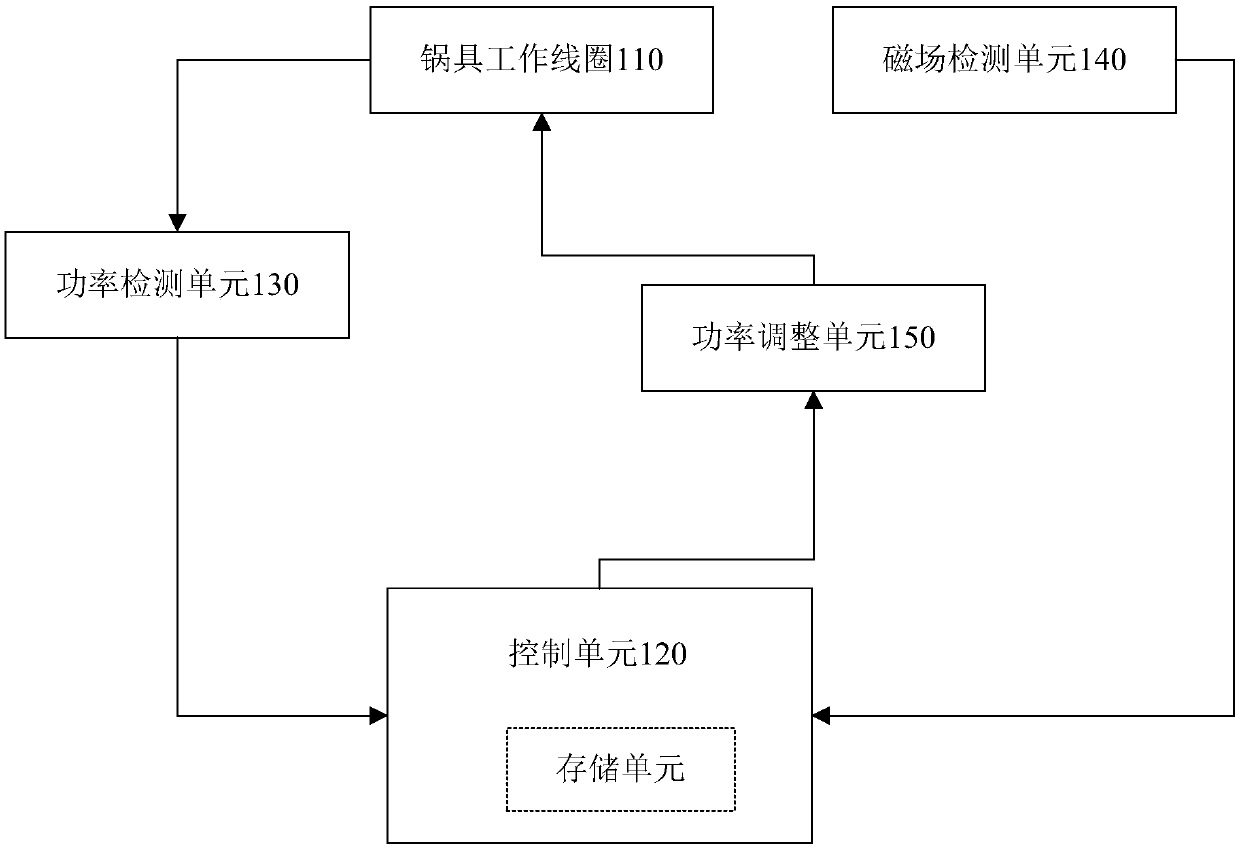

[0036] like figure 1 As shown, in an embodiment of an automatic cooking pot constant power control method of the present invention, the following steps are included: S1, pre-storing the preset input power of the working coil of the pot and the preset of the preset magnetic field strength at the preset position relationship; specifically, when the automatic cooking pot is set, the distance between the pot and the working coil of the pot will be set in advance, when the positional relationship between the pot and the working coil of the pot has been set, when the pot When the input power of the working coil is constant, the actual power received by the cookware is also constant. At the same time, it can also be understoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com