Constant power linear constant current led drive control method and circuit structure

A linear constant current and constant power technology, applied in electric light sources, electrical components, electroluminescent light sources, etc., can solve the problems of stroboscopic, difficult to constant power output, hinder the promotion of LED linear constant current drive, etc., and achieve high efficiency , the effect of constant power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

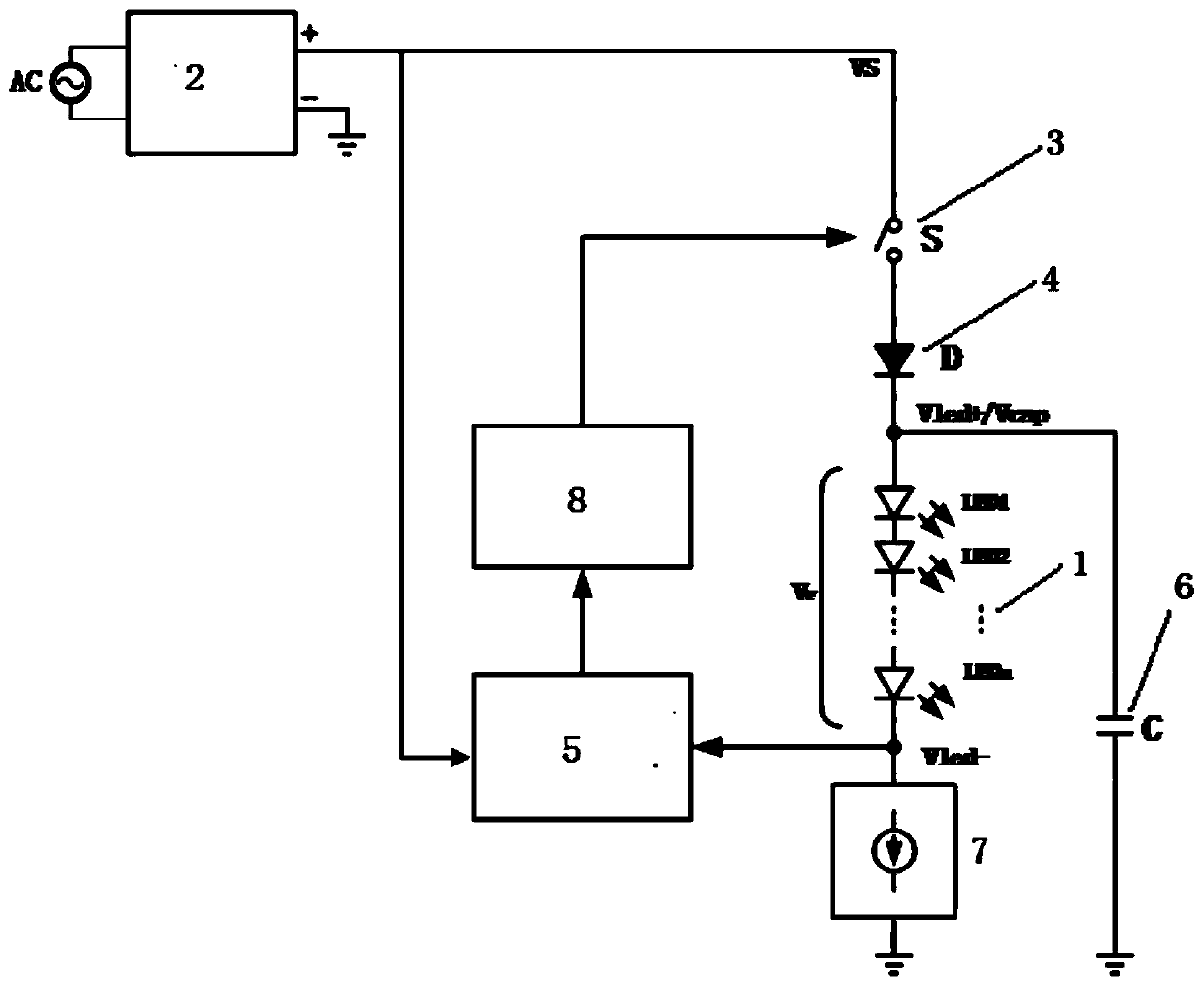

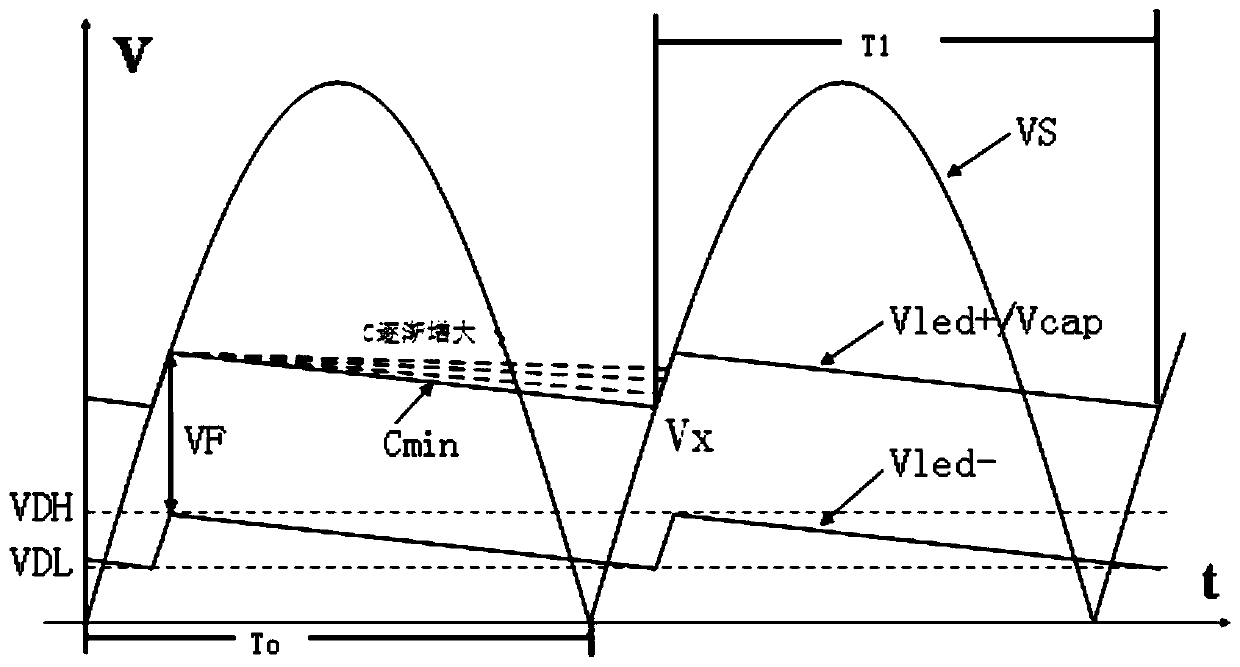

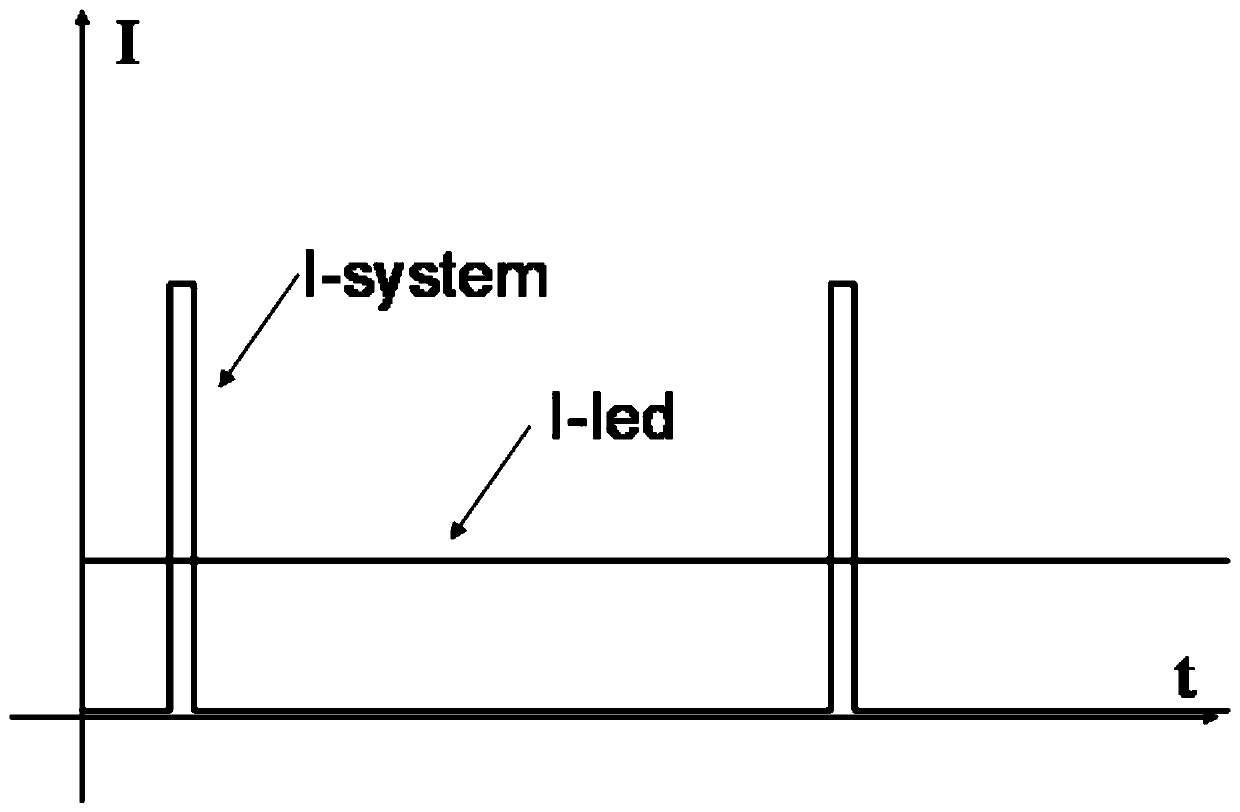

[0024] Embodiment of the present invention: a constant power linear constant current LED drive control method, the drive control method is when the full-wave rectified voltage reaches the sum of the forward voltage drop of the LED light string and the maximum allowable cathode voltage VDH of the light string , the load is powered by the capacitor; when the capacitor voltage drops to the sum of the forward voltage drop of the light string and the minimum allowable cathode voltage VDL of the light string, the full-wave rectified voltage is used to supply power again and the capacitor is charged.

[0025] The specific drive control process is:

[0026] Process 1. The AC input voltage of the LED light string first passes through the rectifier bridge to generate a full-wave rectified voltage VS, and then supplies power to the LED light string. At this time, the period of the full-wave rectified voltage VS is To;

[0027] Process 2. The LED light string with a forward voltage drop o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com