High-strength precise weld pipe welding device

A welding device and high-strength technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of excessive gaps at the joints, weakened strength, poor welding accuracy, etc., and reduce the gap at the joints , Improve welding strength, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

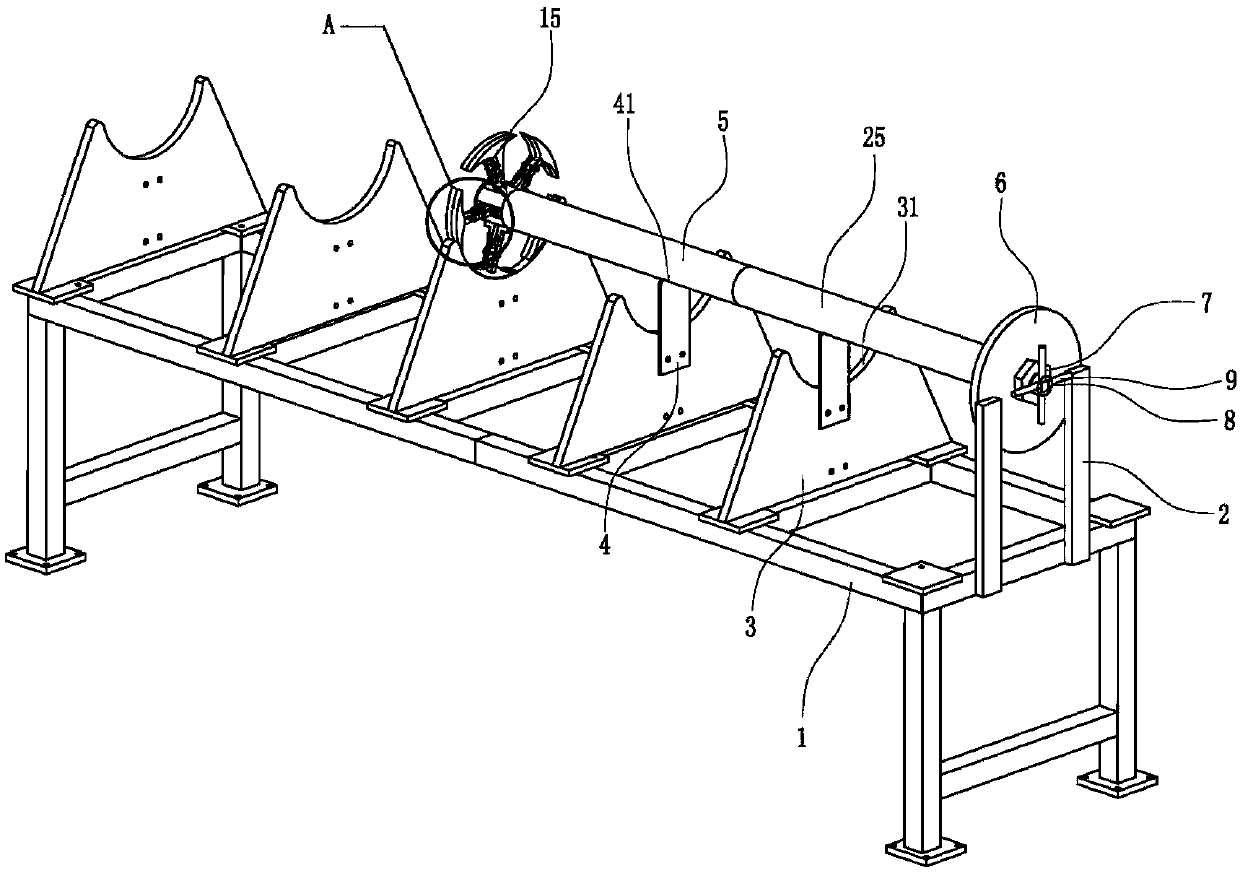

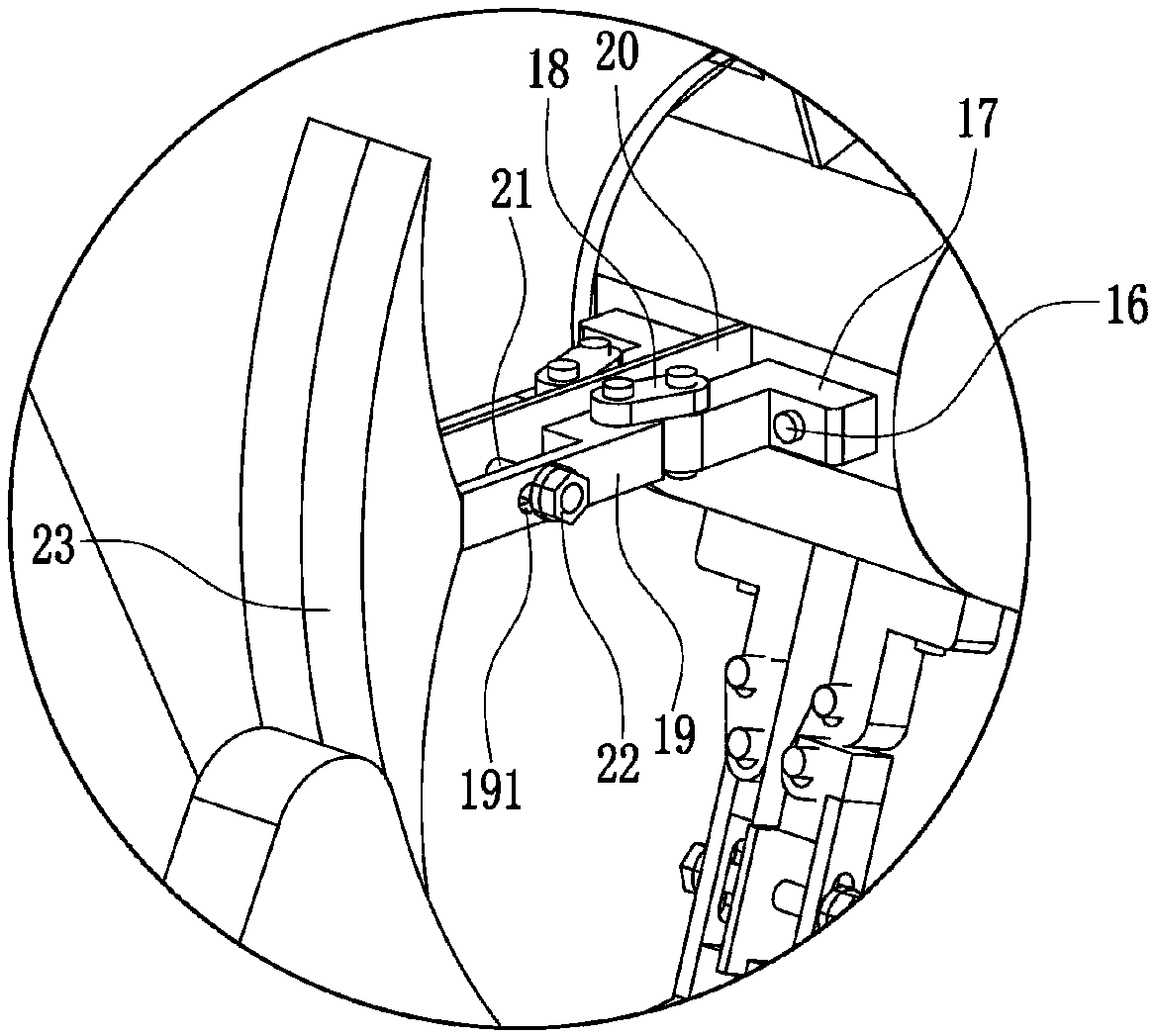

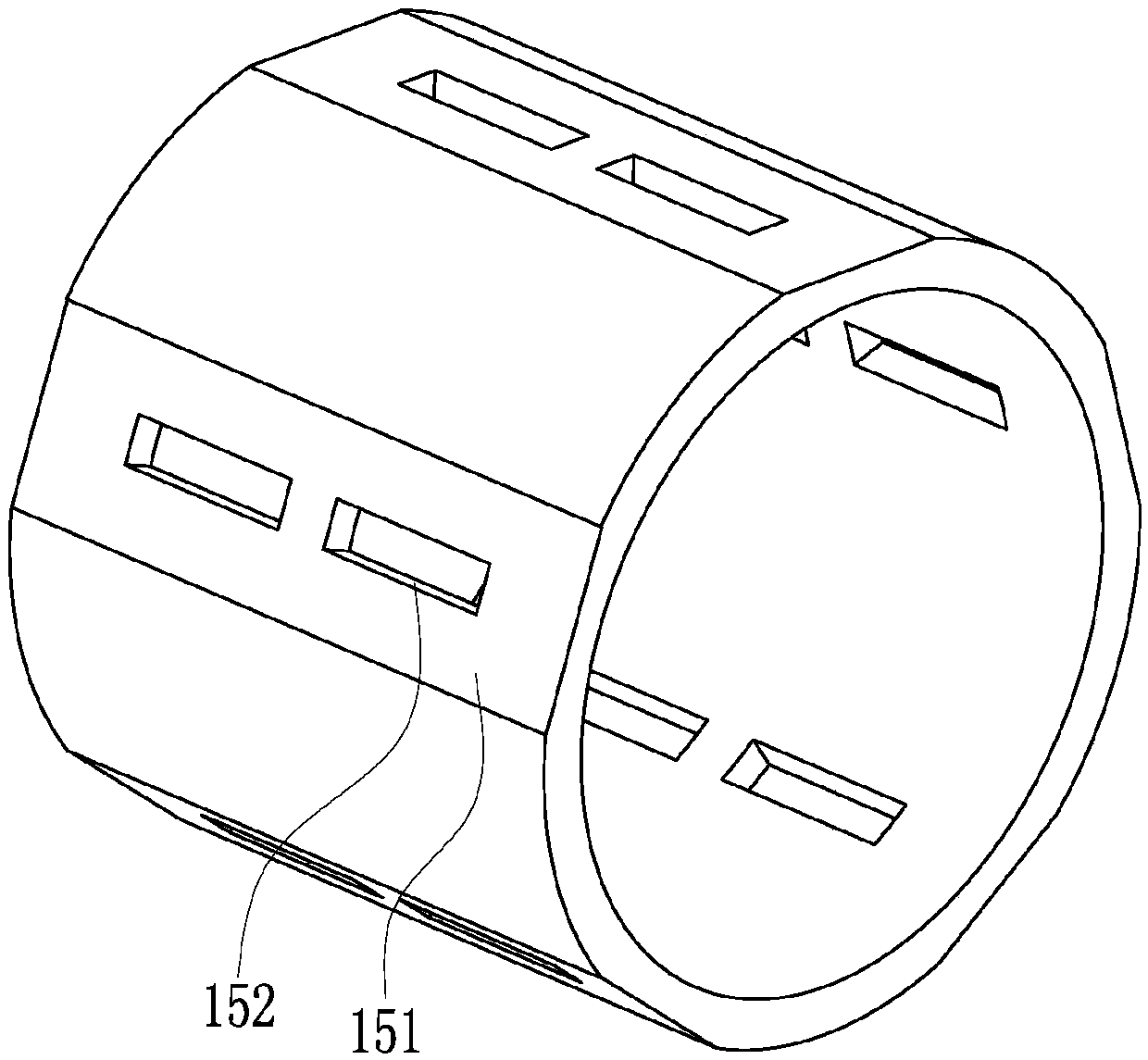

[0018] Such as Figure 1~4 As shown, a high-strength precision welded pipe welding device and operation method include a bracket 1, a stay 2, a supporting plate 3, a supporting bar 4, a chassis 6, a threaded seat 7 and a positioning component; Spaced and vertically distributed supporting plates 3, the upper end of each supporting plate 3 is provided with a first arc groove 31, and one side of each supporting plate 3 is provided with a detachable supporting bar 4, each supporting bar The upper ends of 4 are provided with a second arc groove 41; two symmetrical and vertically distributed stays 2 are fixed above the bracket 1, and a chassis 6 is fixed on one side of the upper ends of the two stays 2; one side of the chassis 6 A through hole 61 is provided, and a threaded seat 7 is fixed on the outside of the chassis 6. The threaded seat 7 is concentrically arranged with the through hole 61. A positioning assembly is arranged in the through hole 61. The positioning assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com