Cutting device for building

A cutting device and construction technology, applied in the field of construction, can solve the problems of prolonged decoration time, low cutting efficiency, easy sore arms, etc., and achieve the effect of reducing labor intensity, improving cutting efficiency, and relieving arm soreness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

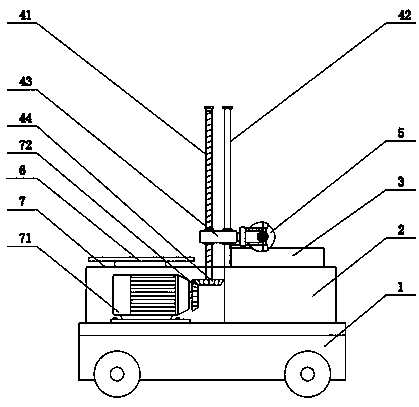

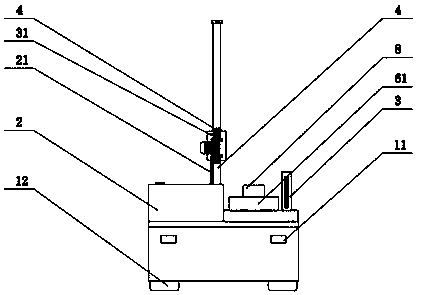

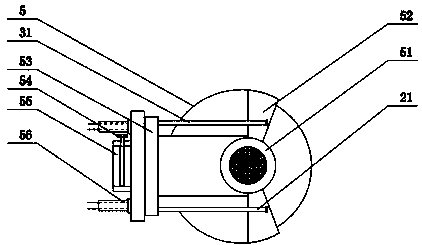

[0019] see Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it includes a mobile base 1, a cooling box 2, a vacuum cleaner 3, a lifting rod 4, a cutting device 5, a power generation assembly 6, a regulating device 7, and a control box 8; Box 2, vacuum cleaner 3, cutting device 4, lifting rod 5, power generation assembly 6, adjustment device 7, and control box 8 are all arranged above the mobile base 1, the vacuum cleaner 3 is arranged on the rear side of the cooling box 2, and the adjustment device 7 is fixedly installed On the left side of the cooling box 2, the power generation assembly 6 is installed on the top of the adjusting device 7, the lifting rod 4 is arranged above the adjusting device 7 and the cooling box 2, and the control box 8 is installed in the middle of the top of the mobile base 1. The cooling The box 2 is provided with a cooling pipe 21, the vacuum cleaner 3 is provided with a suction pipe 31, and the cutting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com