Line pressing and slotting system for corrugated board printing machine

A corrugated cardboard and printing machine technology, applied in the field of corrugated cardboard printing, can solve problems such as individual adjustment, cardboard cracking, and impact on crimping quality, and achieve the effects of reducing high cost and low precision, maintaining positional accuracy, and improving crimping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

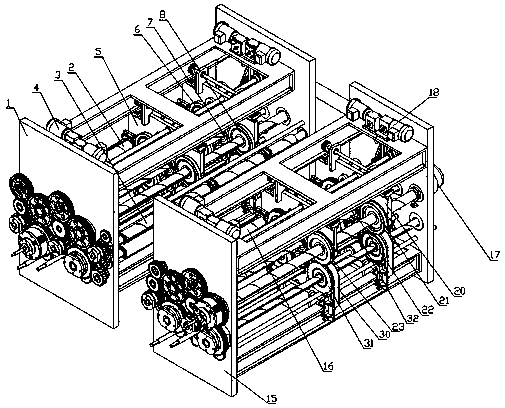

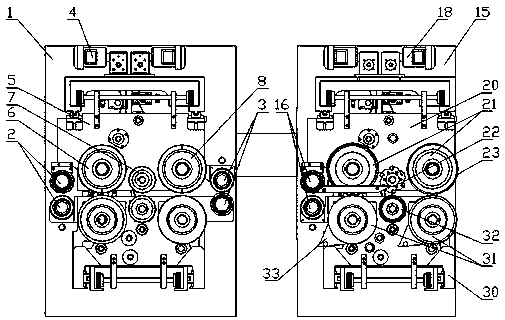

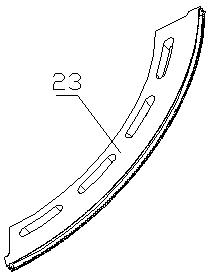

[0013] As shown in the drawings, the present invention includes a crimping machine and a slotting machine, the slotting machine is located at the discharge end side of the crimping machine, and the creasing machine includes a crimping machine frame 1, a crimping paper feed nip roller 2, Crimping output paper pinch roller 3, multiple upper creasing wheel sets, multiple lower creasing wheel sets used in conjunction with the upper crimping wheel sets, and multiple creasing wheel set drive motors 4, creasing paper feeding nip rolls 2 and the crimping and paper-feeding nip rollers 3 are respectively movably installed on both sides of the crimping machine frame 1, and the upper creasing wheel set and the lower creasing wheel set are composed of the creasing wheel mounting seat 5, the first pre-crimping wheel 6, The second pre-crissing wheel 7 and the creasing wheel 8 are composed, and the creasing wheel mount 5 is positioned between the creasing paper feed nip roller 2 and the creasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com