A medicine box automatic folding mechanism

An automatic and medicine box technology, applied in the direction of container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

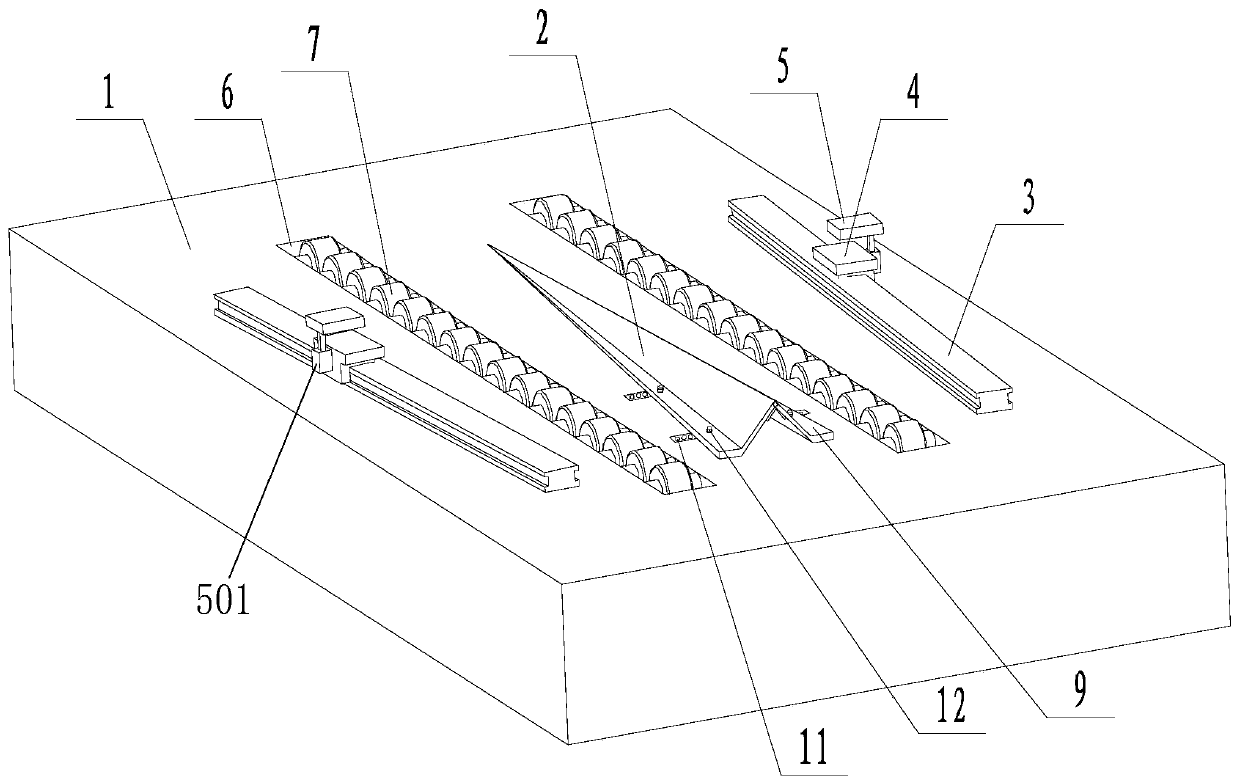

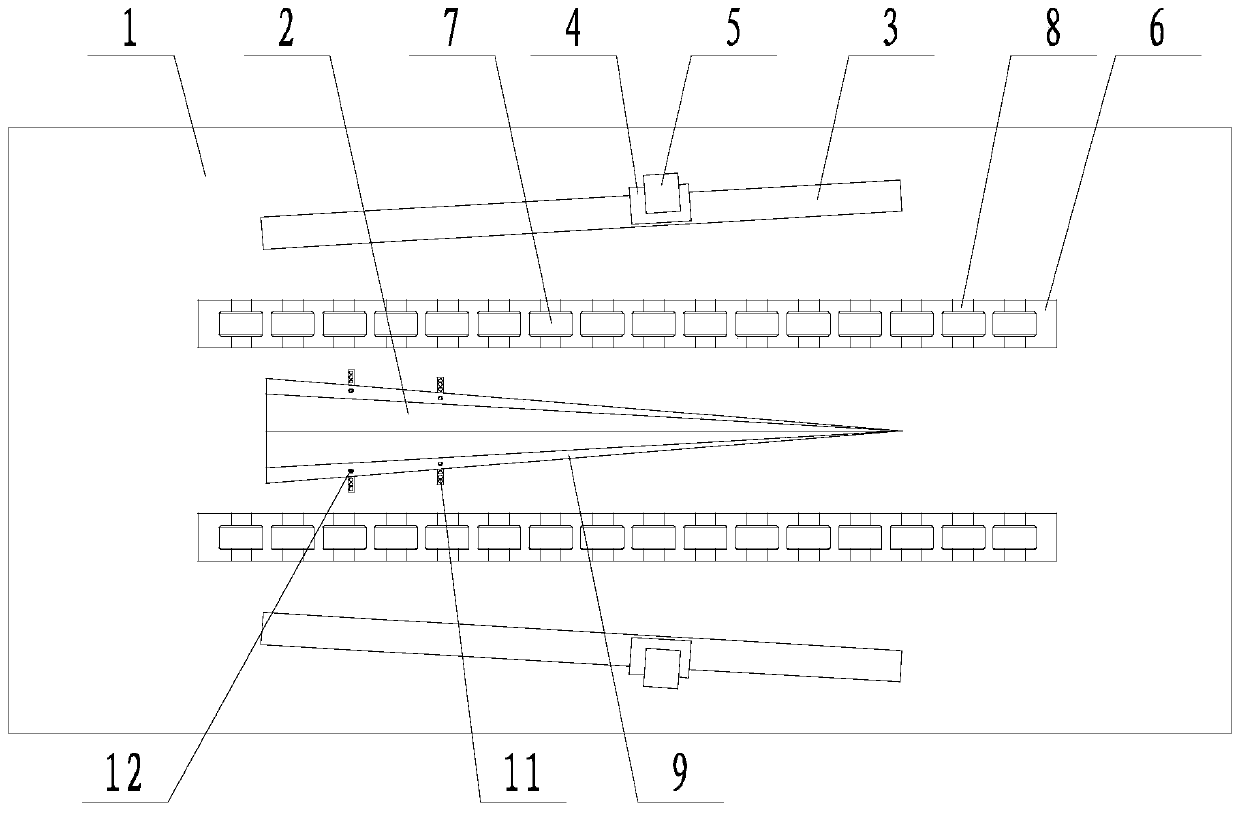

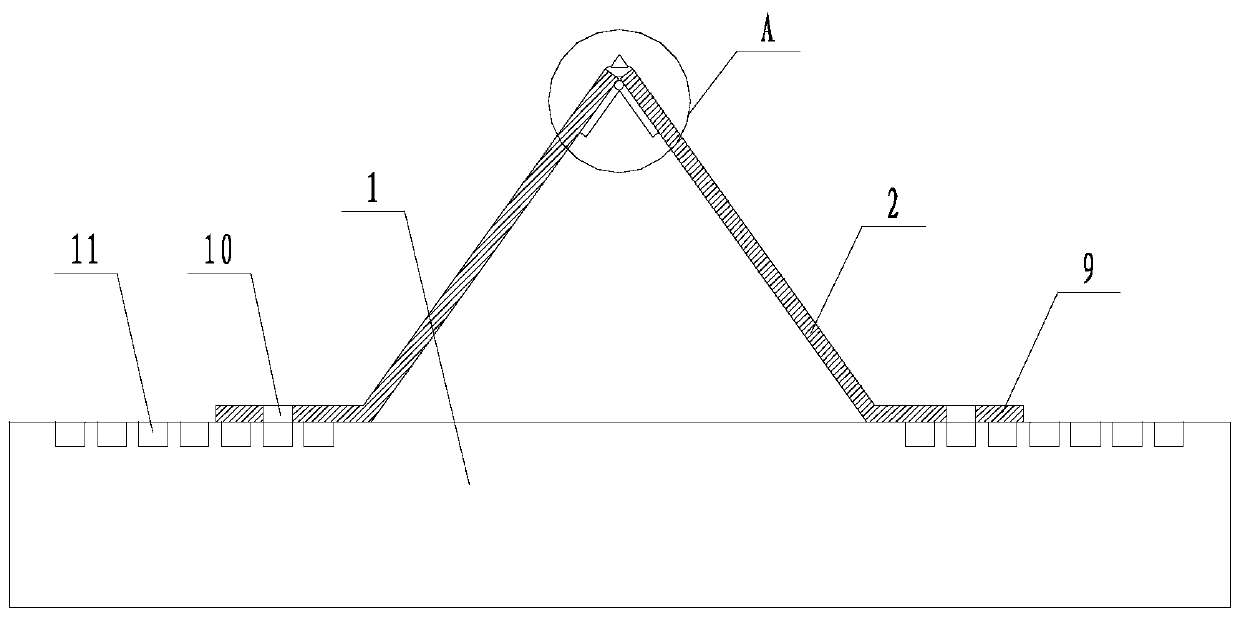

[0033] Such as Figure 1 to Figure 3 The shown automatic hemming mechanism for a medicine box comprises a table body 1, two hemming plates 2 are arranged on the table body 1, the top edges of the two hemming plates 2 are hinged to each other, and the two hemming plates 2 are connected to the The upper surface of the platform body 1 together forms a triangular pyramid structure, and the bottom end of the flanged plate 2 is fixedly connected with the mounting wing 9 that is movably placed on the platform body 1, and the threaded through hole 10 is set on the mounting wing 9, and the The bottom surface of the triangular pyramid structure is perpendicular to the platform body 1 upper surface, and the bottom surface of the triangular pyramid structure is an isosceles triangle with the apex facing up. The opposite sides of the triangular pyramid structure are all provided with guide mechanisms fixed on the platform body 1, and the guide mechanism is fixed on the platform body 1. The...

Embodiment 2

[0036] Such as Figure 1 to Figure 6 As shown, on the basis of Embodiment 1, the flanged plate 2 and the corresponding mounting wing 9 are integrally formed. The tops of the two flanging plates 2 are hinged by hinges 15 arranged on the bottom surfaces of the flanging plates 2, and elastic members 13 are bonded between the tops of the two flanging plates 2, and the bottoms are inserted into the elastic members 13. A hard pointed cone 14, the pointed end of the hard pointed cone 14 faces upward. The top surface of the slide block 4 is parallel to the upper surface of the table body 1, and the side of the slide block 4 away from the direction where the triangular pyramid structure is located is fixedly connected to the linear drive device 501 with the driving end facing upward, and the drive end of the linear drive device 501 is fixedly connected Clamping plate 502, the clamping plate 502 is located above the slider 4, the bottom surface of the clamping plate 502 is parallel to ...

Embodiment 3

[0038] Such as Figure 7 As shown, the linear guide rail 3 is fixedly connected with a mounting wing 9 far away from itself. Each linear guide rail 3 is fixedly connected with the fixed mounting wing 9 by two connecting rod assemblies 16, and the connecting rod assemblies 16 are located inside the platform body 1, and the platform body 1 is hollow, and the connecting rod assemblies 16 can be mounted on the platform body 1 move within. In this embodiment, a notch 17 for the connecting rod assembly 16 to pass through and move is provided on the upper surface of the table body 1 , and the length and width of the notch 17 can be adaptively set according to the lateral adjustment range of the mounting wing 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com