Shifting tool for mooring rope and mooring winch

A technology for mooring boats and ropes, applied in tethering, transportation and packaging, ships, etc., can solve the problems of complex structure, lack of labor saving, operability, and inability to effectively use reels, etc., to improve operability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

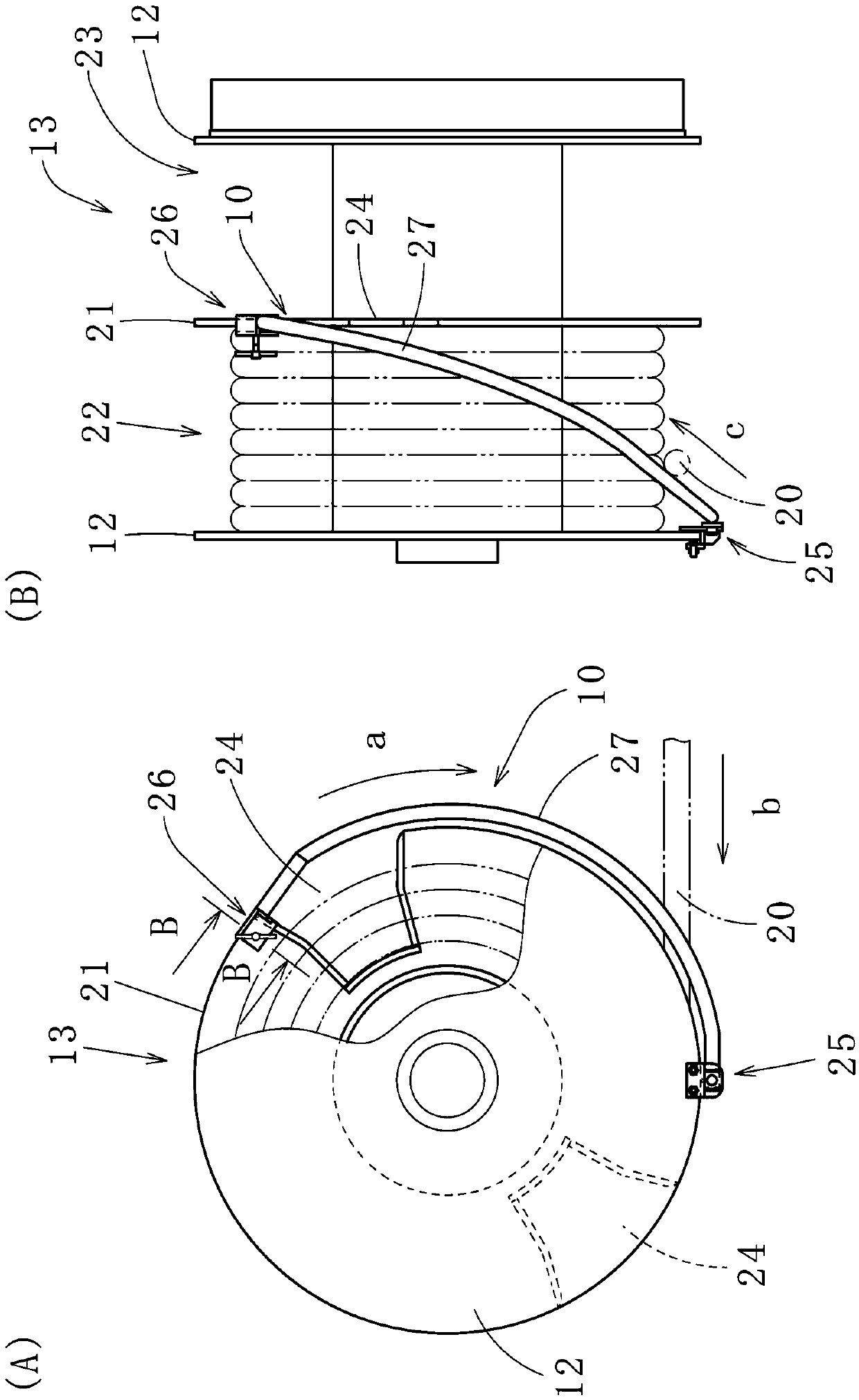

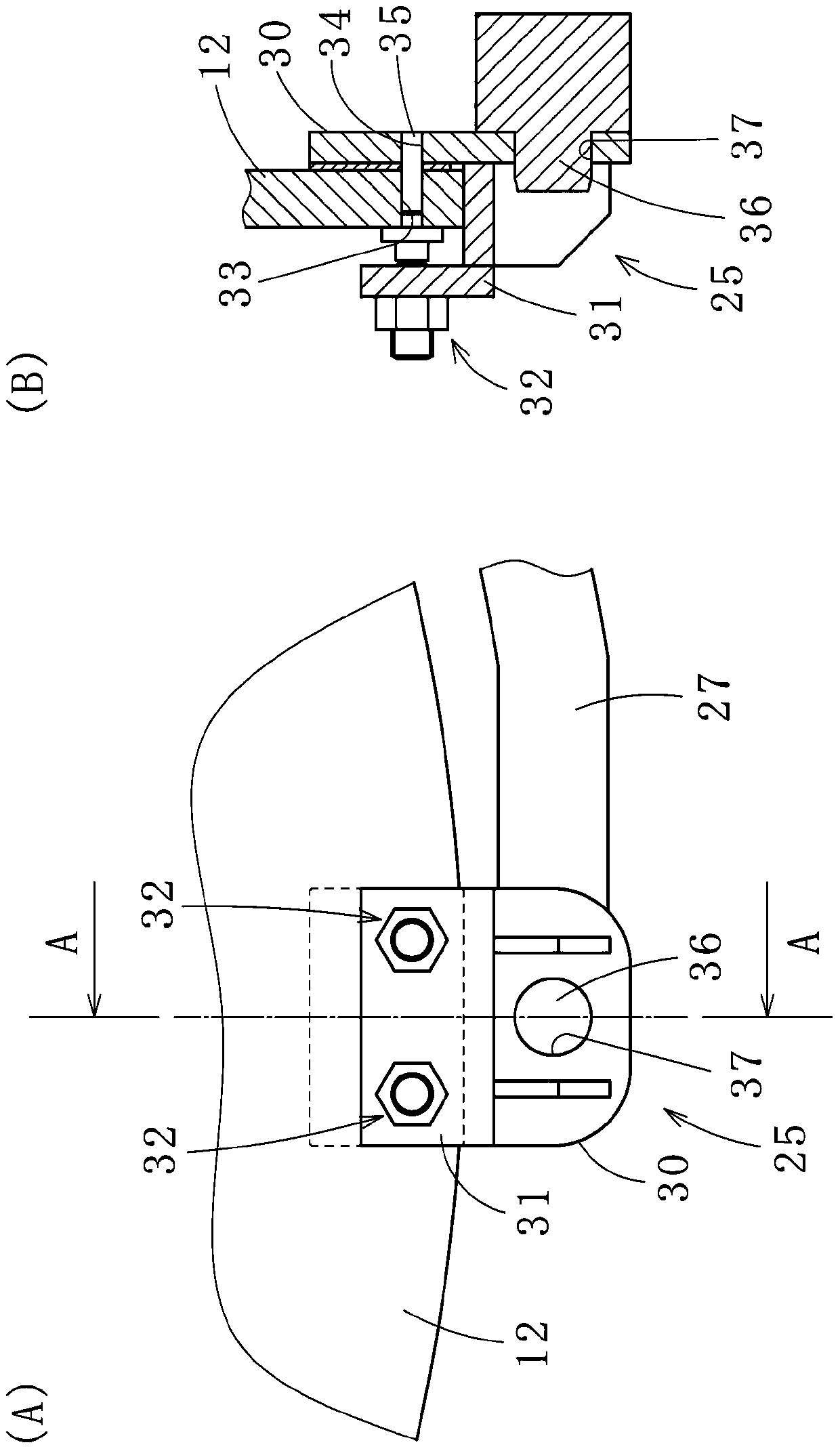

[0027] Next, embodiments in which the present invention is embodied will be described with reference to the drawings for understanding the present invention.

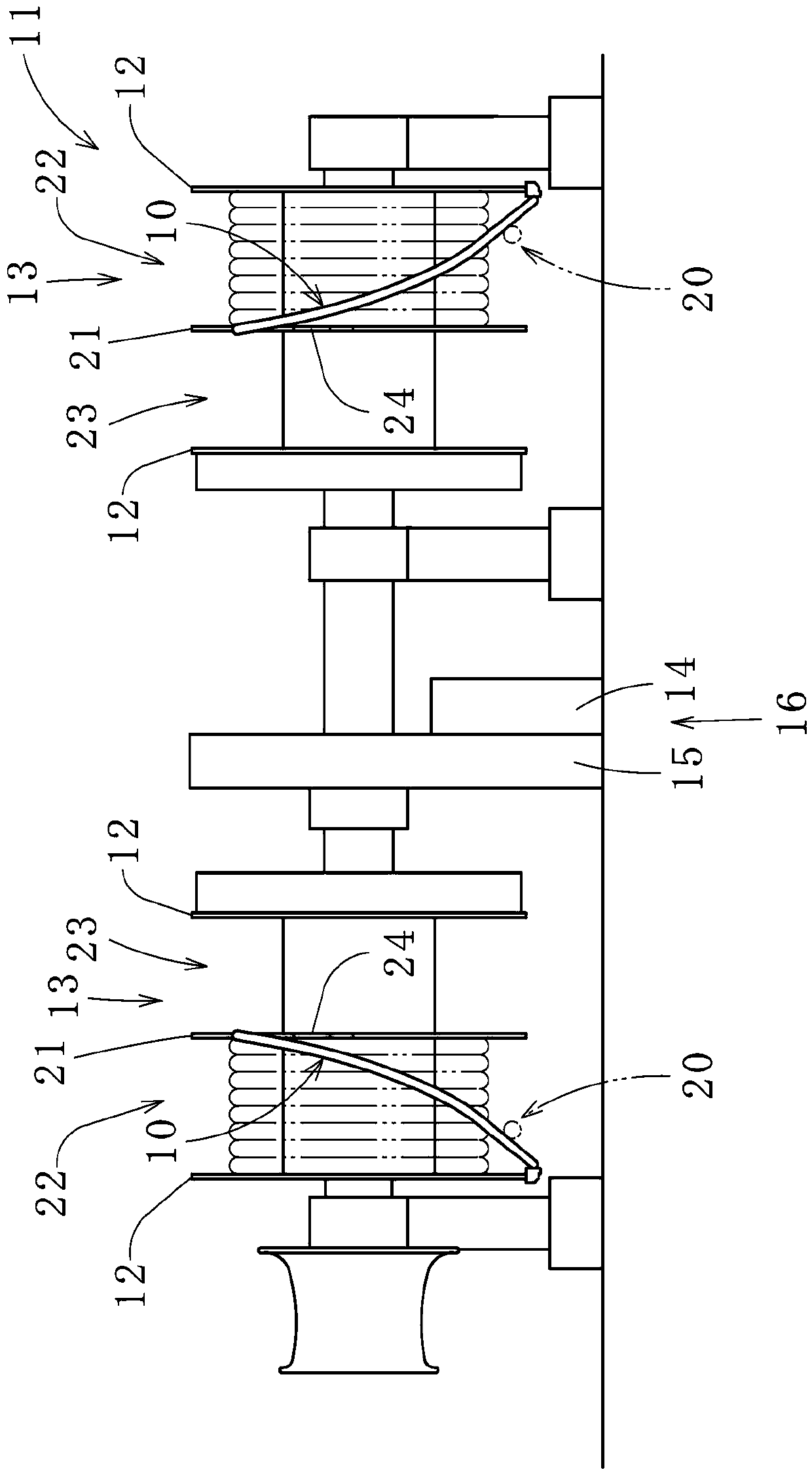

[0028] Below, refer to Figure 1 ~ Figure 4 The mooring winch 11 provided with the mooring rope rehanger 10 which concerns on one Embodiment of this invention is demonstrated.

[0029] The mooring winch 11 is mainly mounted on ships such as crude oil tankers for mooring operations. Such as figure 1 As shown, a general mooring winch 11 has a structure in which two reels 13 are symmetrically arranged left and right, and each reel 13 is rotated by a drive unit 16 composed of a drive motor 14 and a speed reducer 15 in the center to moor the boat. The two drums 13 have outer flanges 12 on both sides for winding up and sending out the rope 20 . In addition, the side where the mooring rope 20 enters into the reel 13 is set as the front of the mooring winch 11, and the structures and actions of the two reels 13 are left-righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com