Device for washing textile cotton cloth after dyeing

A cleaning device, cotton cloth technology, applied in the processing of textile materials, textile and papermaking, liquid/gas/steam textile material processing, etc. Good drying effect and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

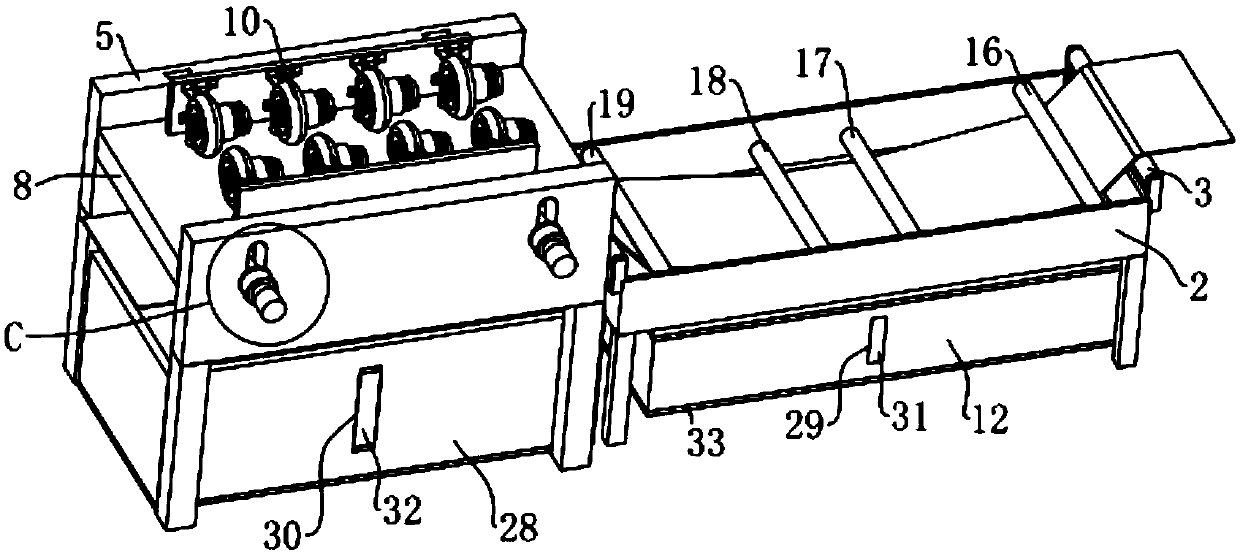

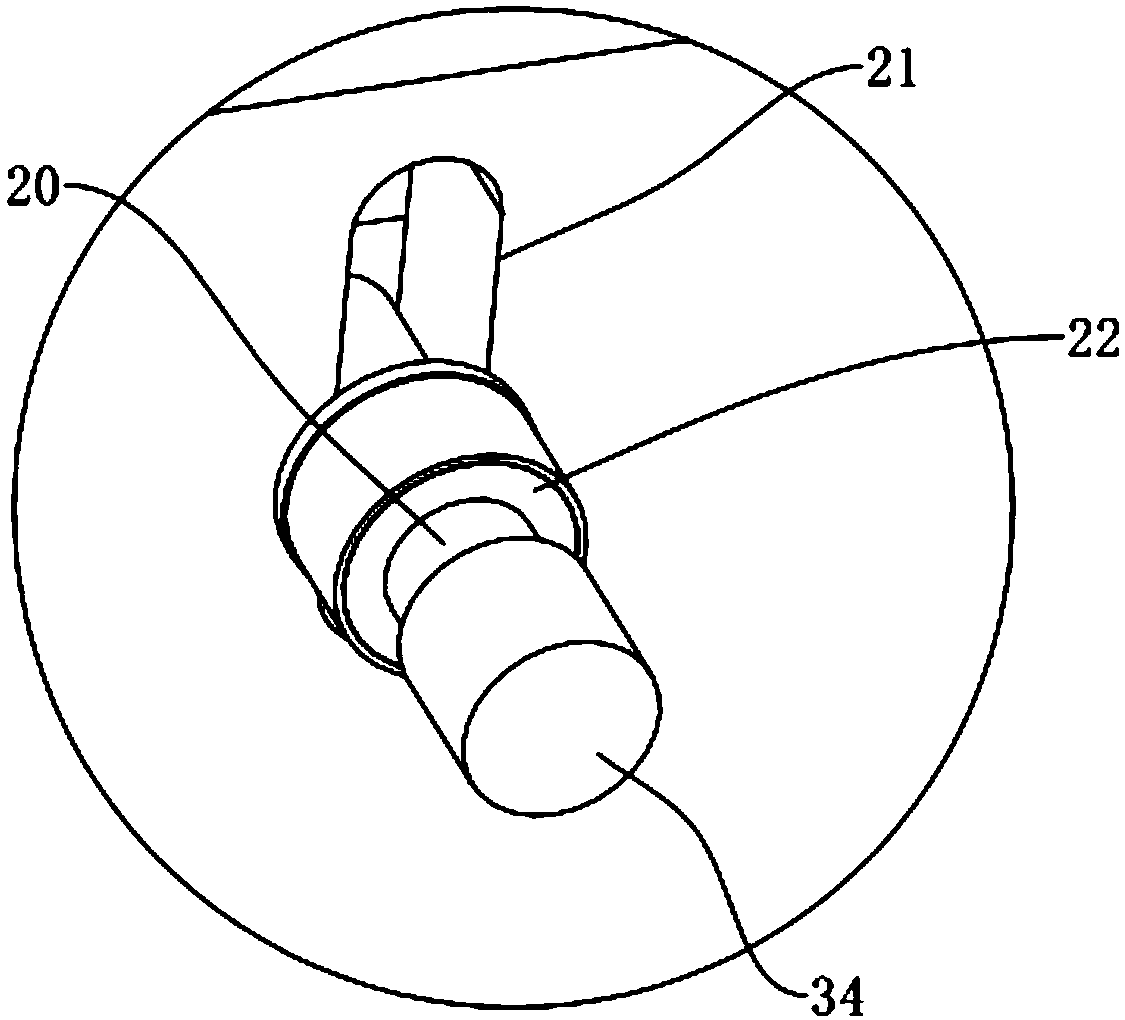

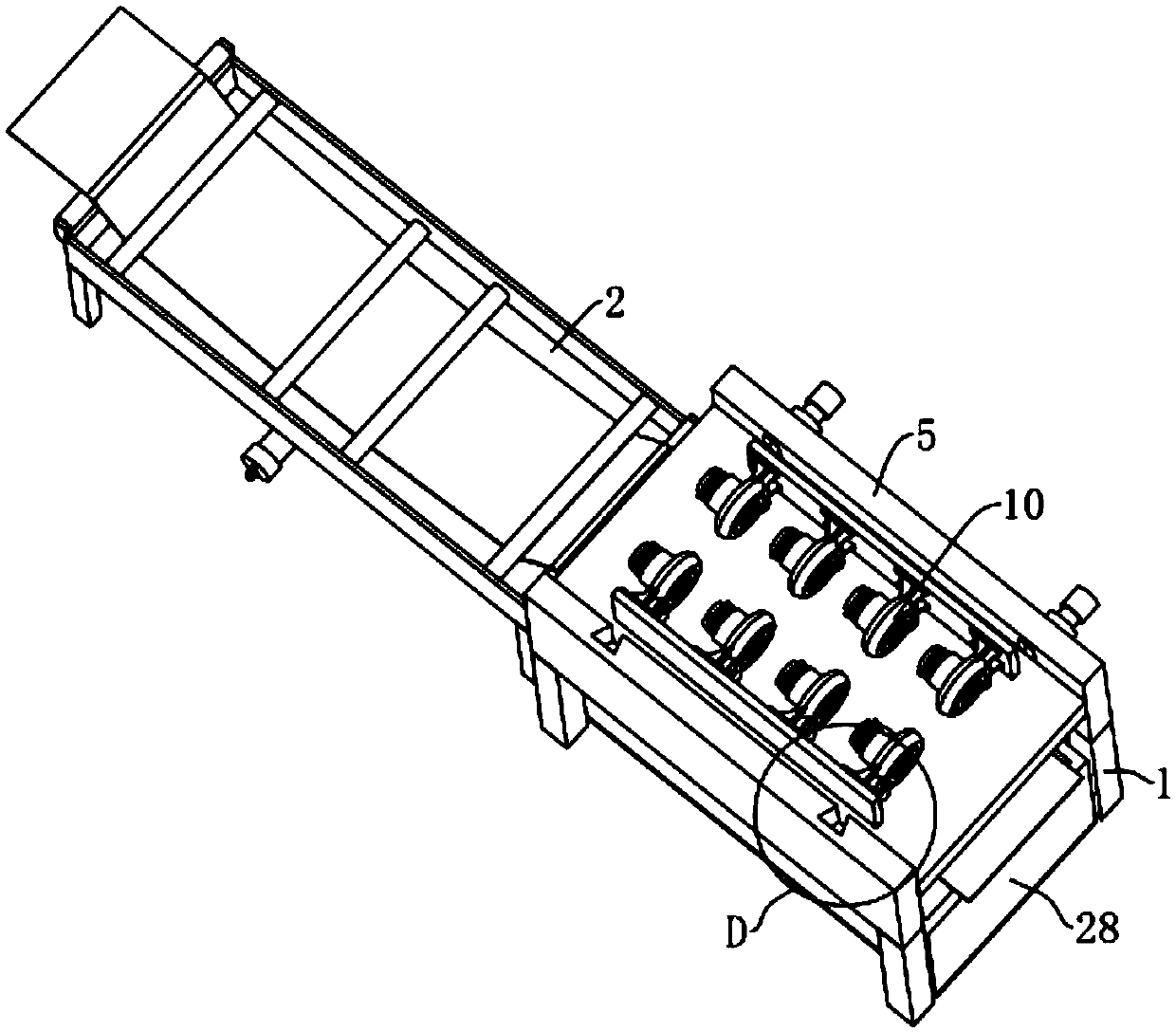

[0035] Such as Figure 1 to Figure 6 As shown, a cleaning device for textile cotton after dyeing includes a frame 1, wherein a clean water tank 2 is fixed on the frame 1, and clean water can be contained in the clean water tank 2, and the dyed textile cotton needs to be washed with water. In order to make the textile cotton cloth stably enter the clean water tank 2, the first rotating roller 3 and the second rotating roller 4 are connected to the two ends of the clean water tank 2, and there is also a press for pressing the textile cotton cloth inside the clean water tank 2. Department; in order to dry the cleaned textile cotton cloth, two fixed plates 5 are also fixed on the frame 1, and four upper squeezing rollers 6 and four lower rollers are connected in rotation between the two fixed plates 5 The squeeze roller 7 is connected with a bellows 8 slidingly along the vertical direction between the two fixed plates 5, and a resistance heating wire 9 is arranged inside the bello...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap