Tunnel-form prestressed pipe curtain structure and construction method thereof

A prestressed pipe and construction method technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of difficulty in guaranteeing strength and precision requirements, difficult construction, etc., to reduce additional engineering procedures and costs, low cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manner of the present invention will be further described in detail through the description of the best embodiment below.

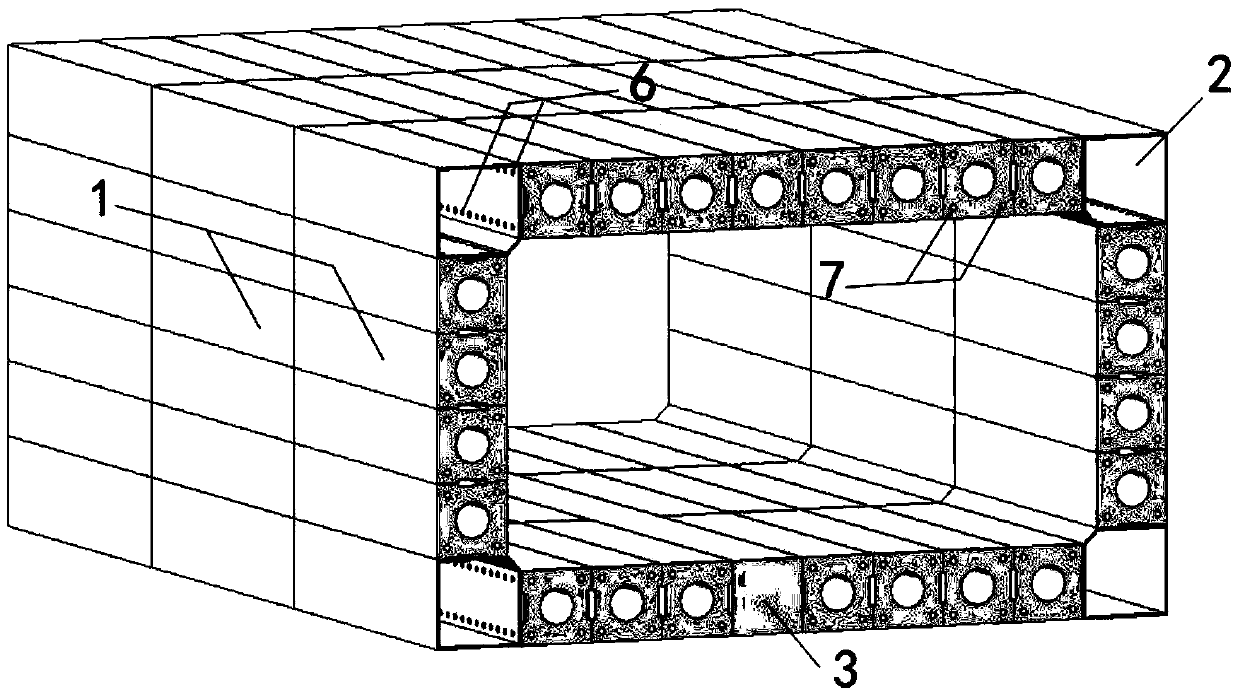

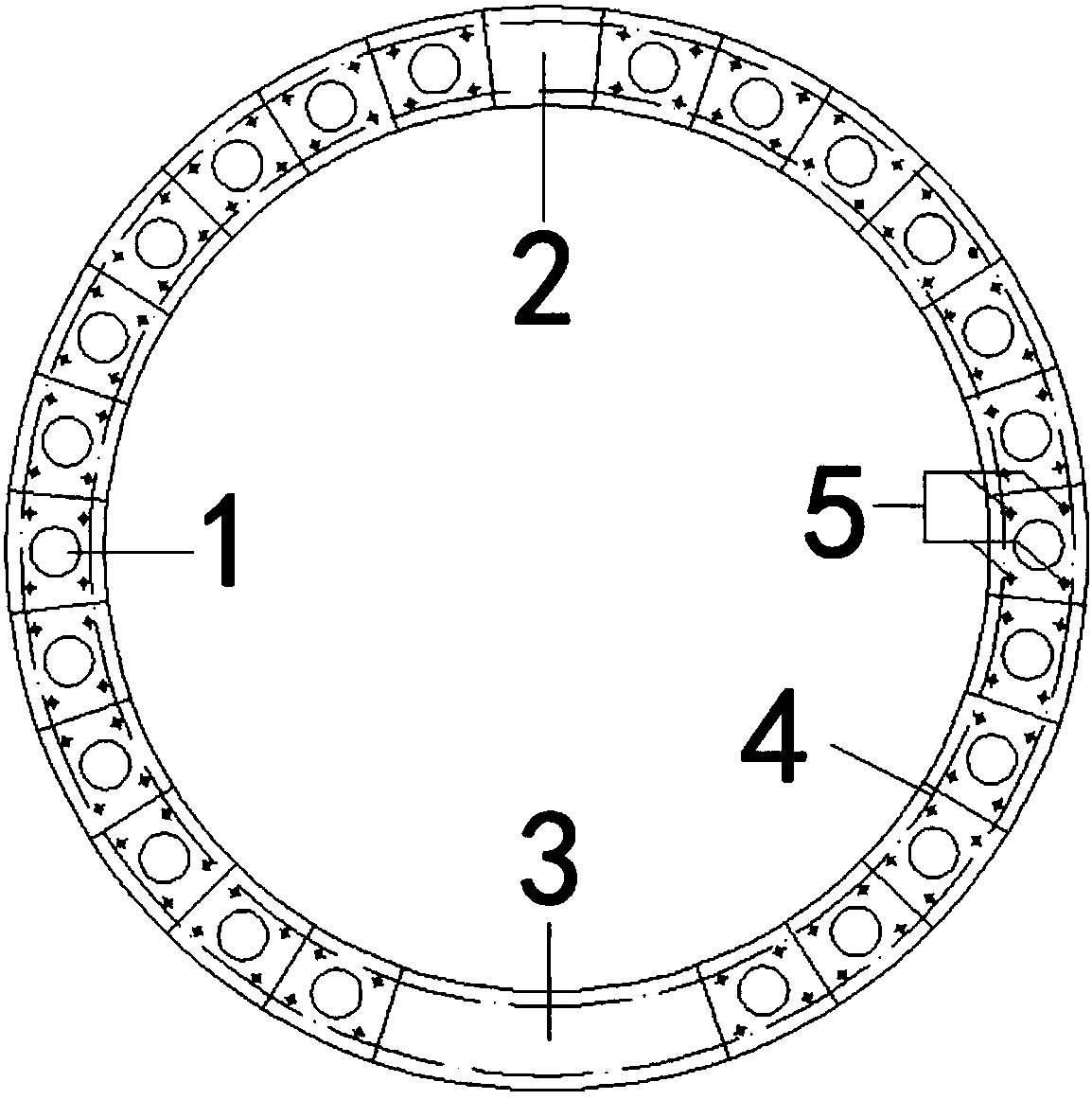

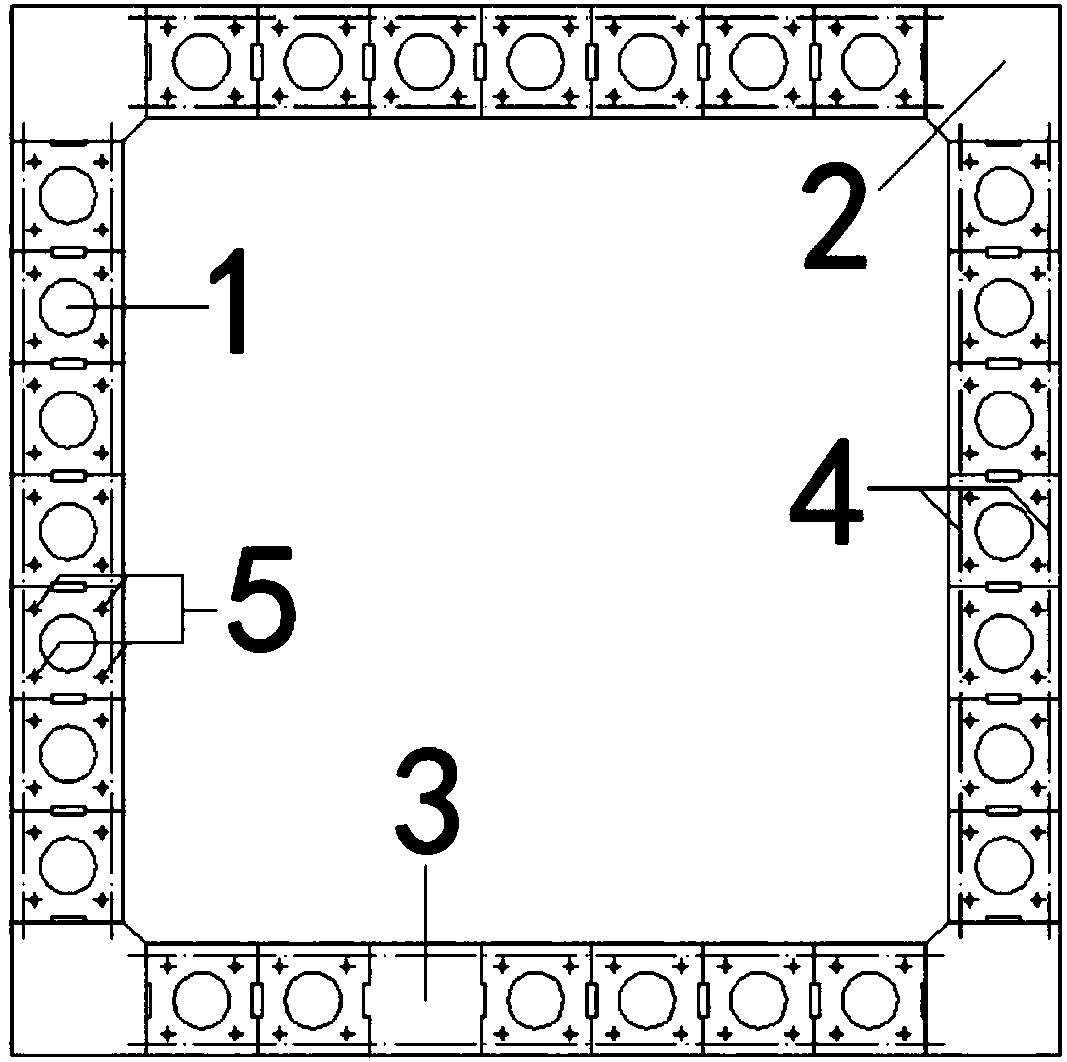

[0059] Such as figure 1 As shown, the tunnel form prestressed pipe curtain structure of the present invention is composed of several prefabricated concrete beams 1, prefabricated steel units 2, a concrete cast-in-place section 3, several transverse prestressed tendons 4 and longitudinal prestressed tendons 5, and the several prefabricated Concrete beams 1 are connected by locking and joint grouting, and form a whole by tensioning transverse prestressing tendons 4 and longitudinal prestressing tendons 5; the prefabricated steel unit 2 serves as a construction platform for transverse prestressing tendons 4, and is a number of prefabricated concrete beams. The beam 1 is prestressed in the hoop or transverse direction; the concrete cast-in-place section 3 is located at the bottom of the pipe curtain structure, and is the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com