Method for controlling clutch of vehicle with automated manual transmission

A manual transmission and clutch technology, applied in the field of clutches, can solve the problems of transmission durability decline and achieve the effects of improving durability, reducing shift control time, and reducing micro-slip control time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

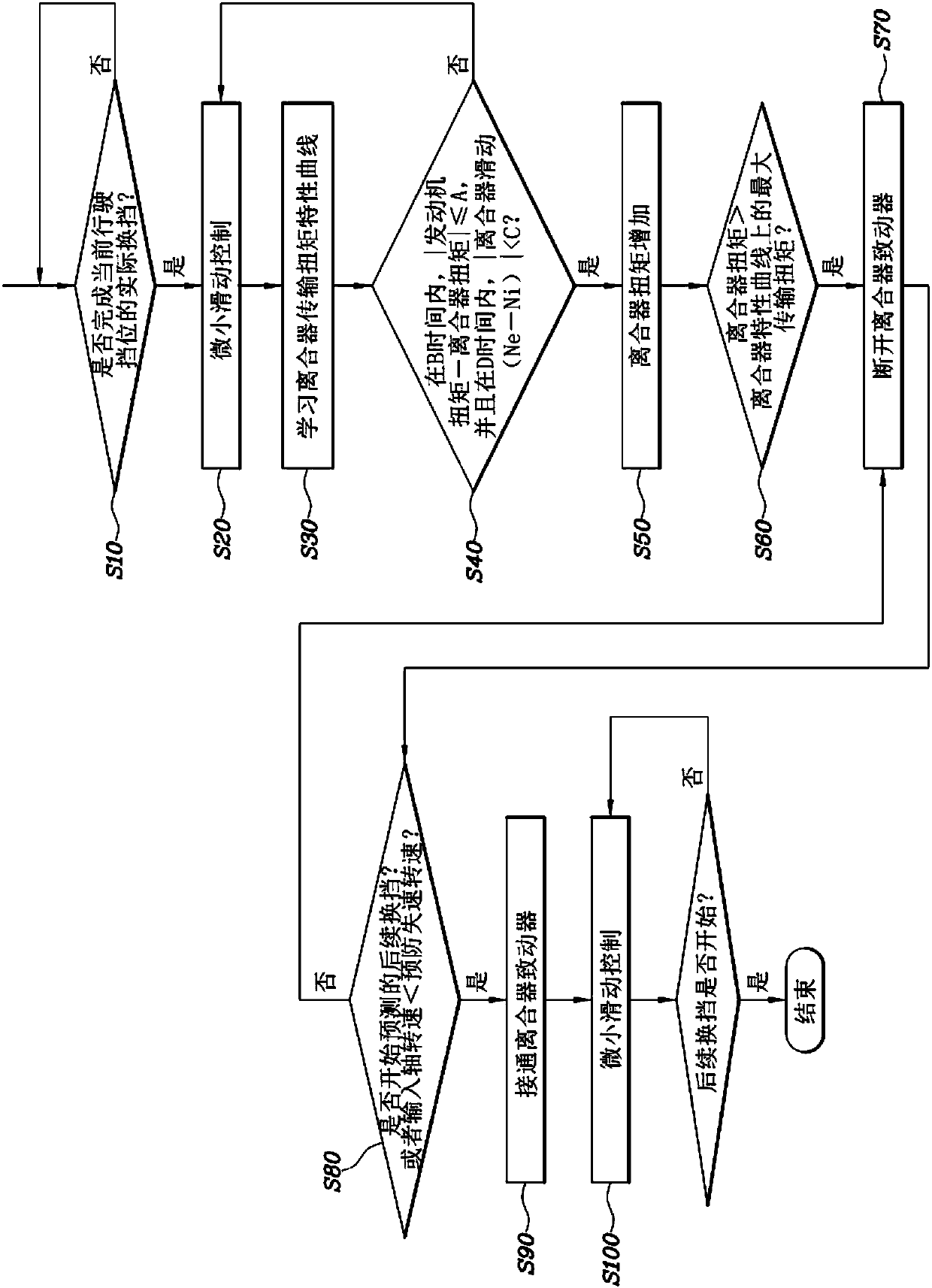

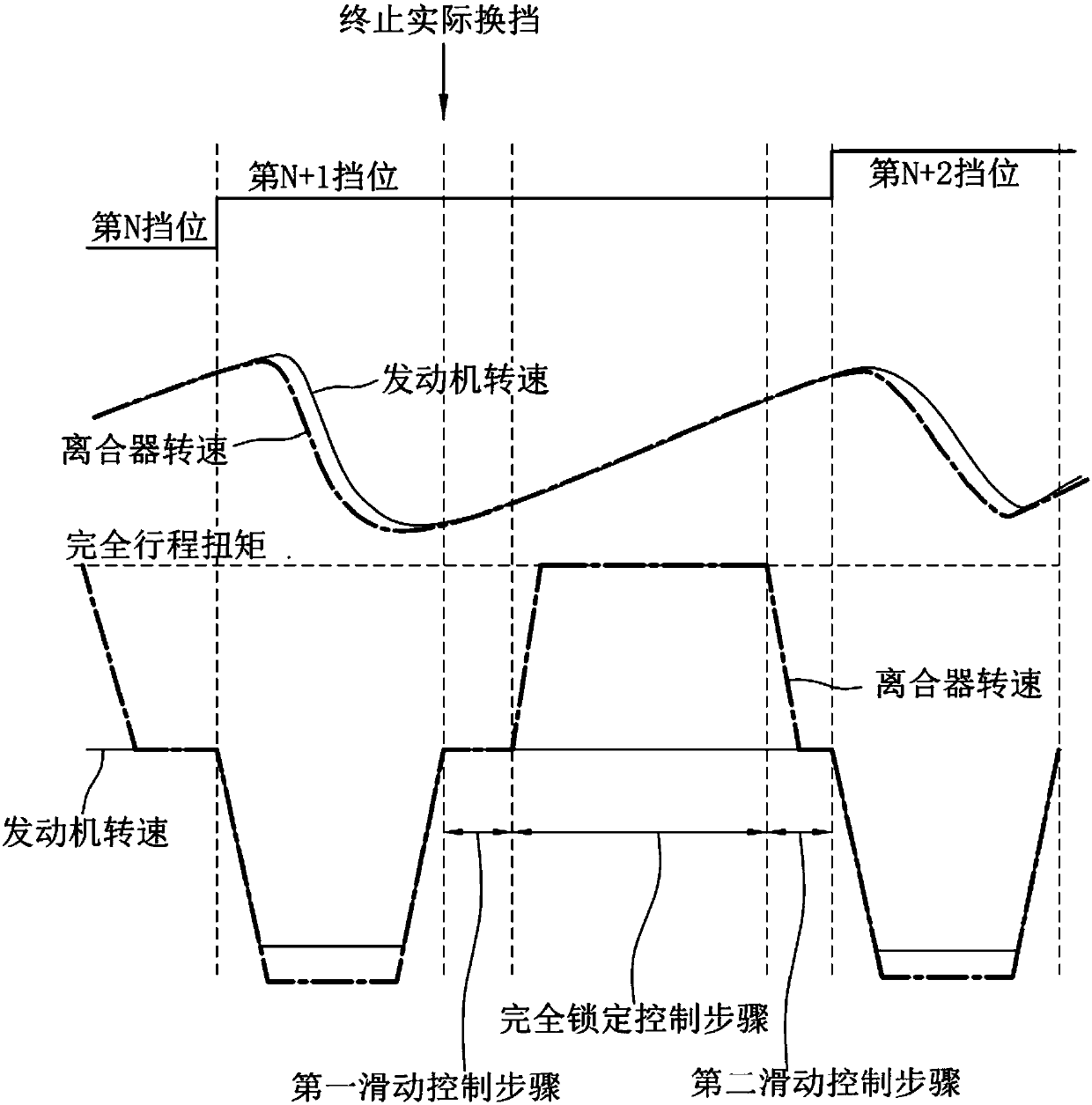

[0024] In some forms of the invention, a method of controlling an AMT vehicle clutch may be configured to include a first slip control step, a full lock control step, and a second slip control step.

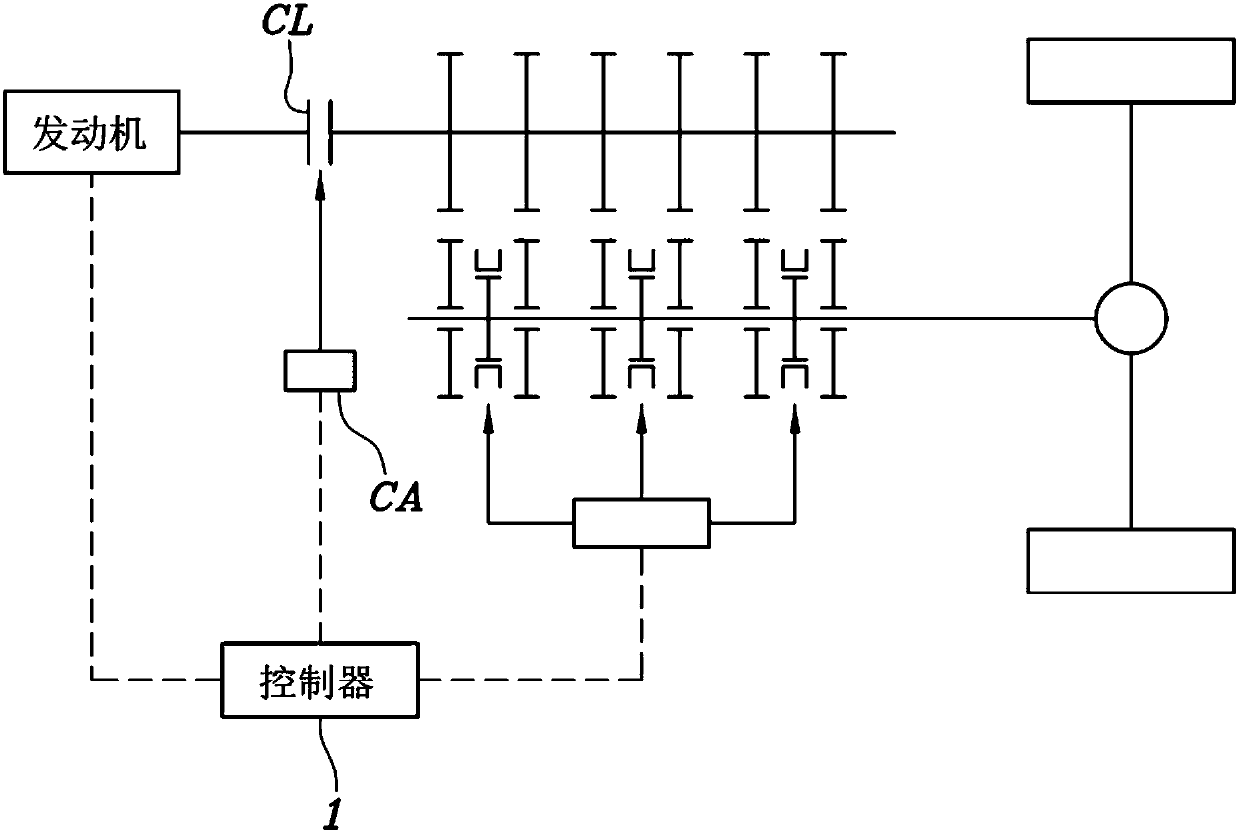

[0025] will refer to figure 1 The present invention will be specifically described. First, at the first slip control step, when a shift to a current gear is completed while the vehicle is moving, the controller 1 may perform a slight slip control of the clutch (CL), thereby learning transmission torque characteristics of the clutch.

[0026] For example, in order to learn the transmission torque characteristic of the clutch, the clutch (CL) is controlled to slip slightly. When the transmission gear is engaged whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com