Electric water heater with high hot water output rate and method for improving hot water output rate of electric water heater

A technology for electric water heaters and hot water output, applied to water heaters, fluid heaters, lighting and heating equipment, etc., to achieve the effects of increasing hot water output rate, saving energy, and reducing hot and cold mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

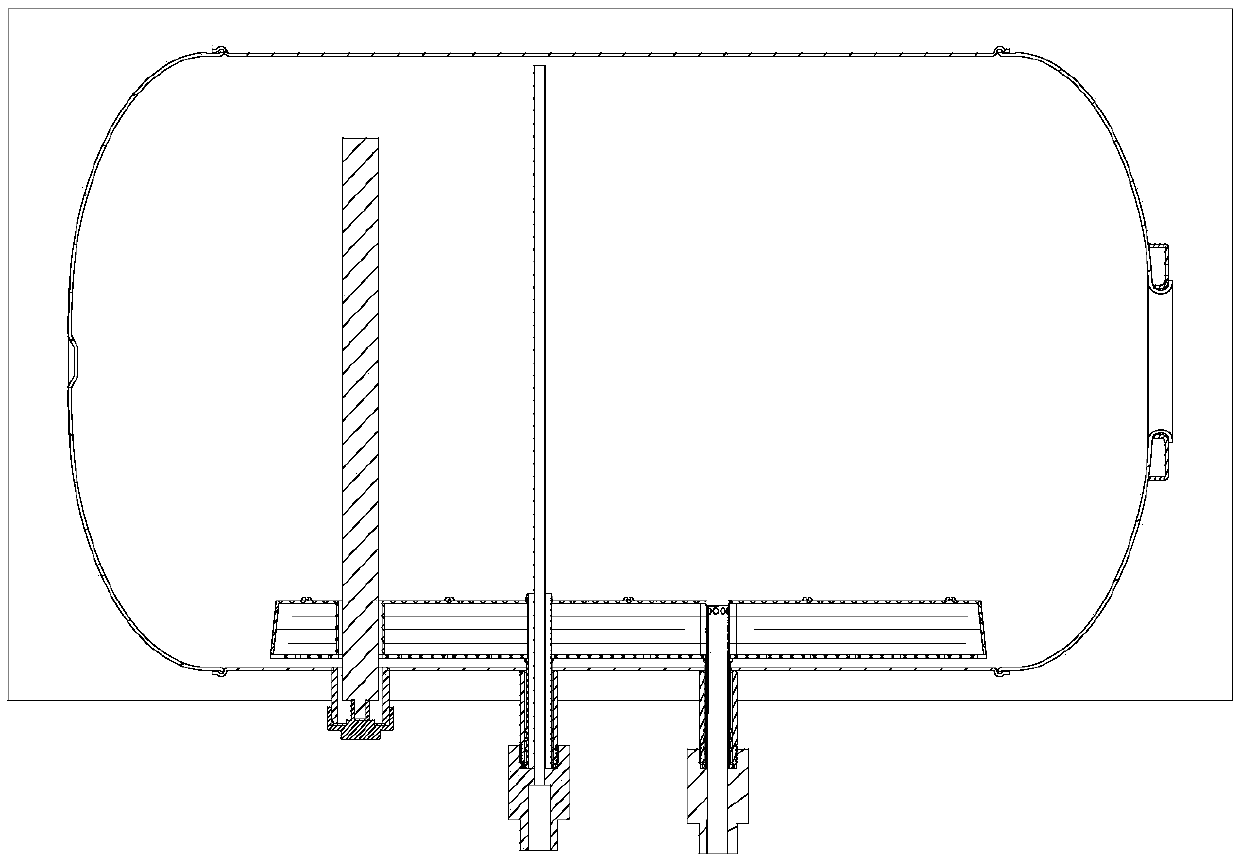

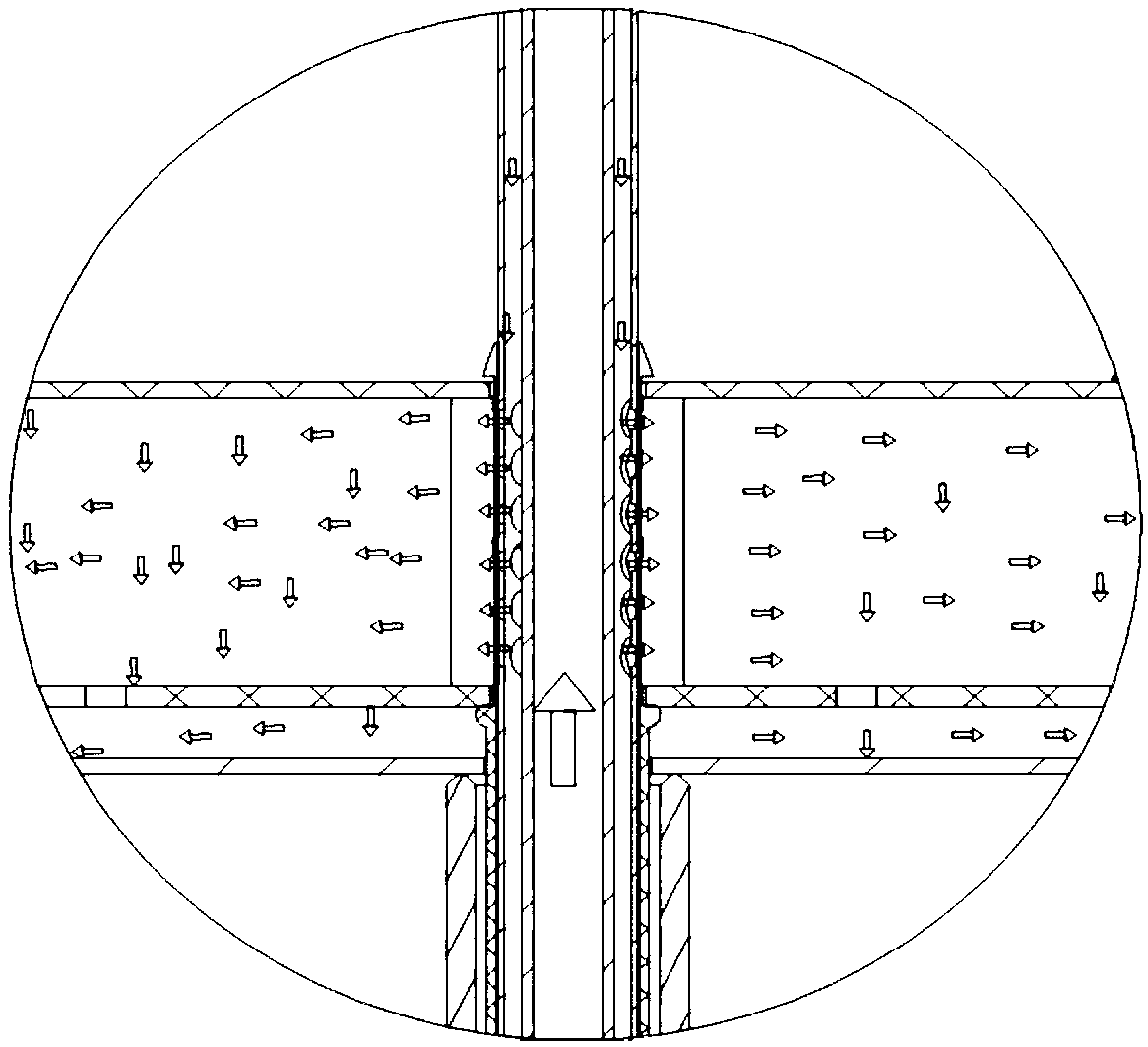

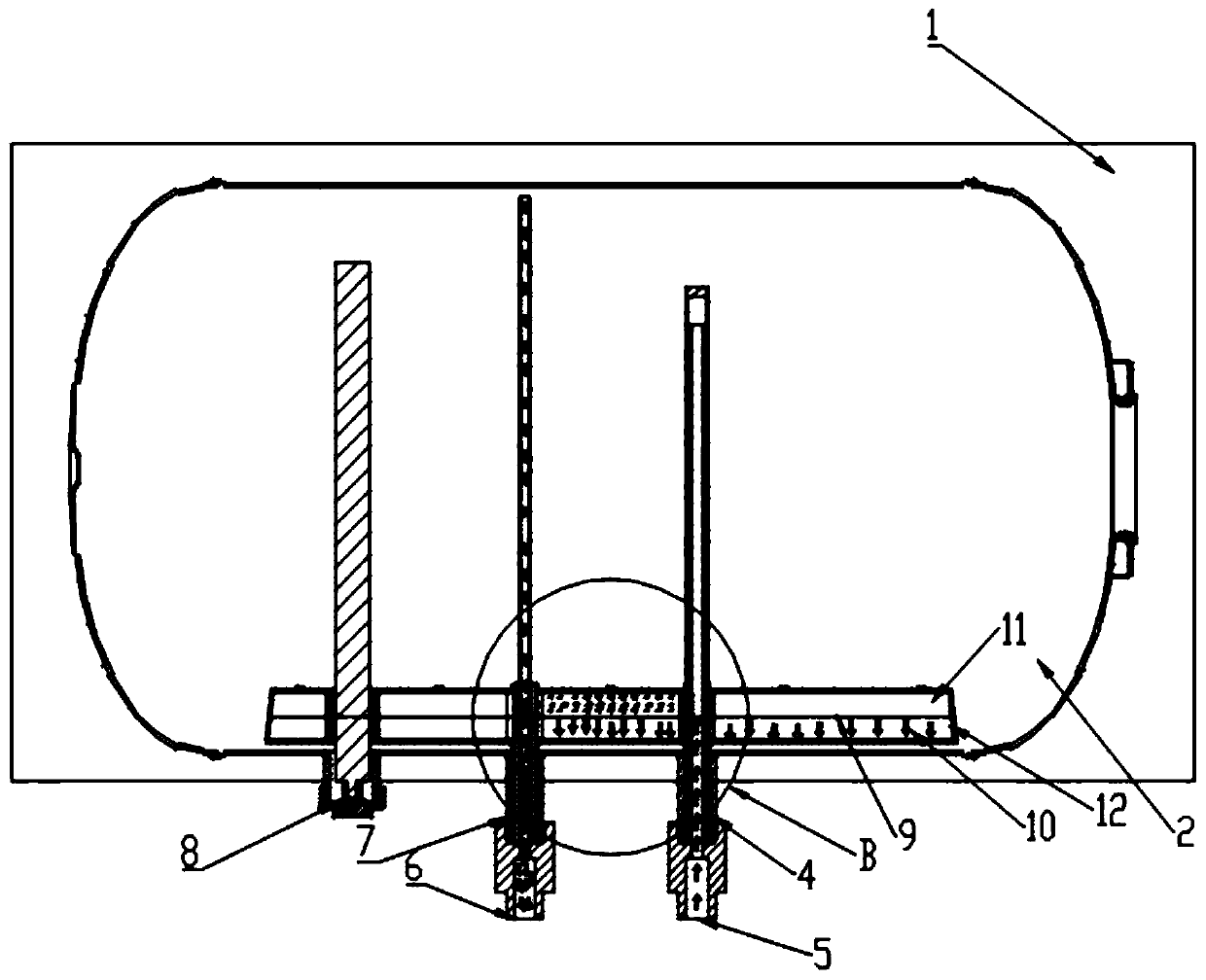

[0035] Such as image 3 , Figure 4 As shown, an electric water heater with a high hot water output rate includes: a housing 1, an inner tank 2, a water inlet pipe 5 installed on the inner tank 2, a water outlet pipe 6, a magnesium rod assembly 8 and a heating device; it is characterized in that A water mixing device 10 is installed in the lower space of the inner tank 2, the water inlet pipe 5 and the water outlet pipe 6 are connected to the water mixing device 10, and several The water inlet hole is provided with a water mixing hole communicated with the water mixing device 10 on the water outlet pipe 6. After the water in the water inlet pipe 5 enters the water mixing device 10, a part passes through the water inlet hole Enter the inner tank 2, and the other part enters the outlet pipe 6 through the mixing hole 11.

[0036] Wherein, both the water inlet pipe 5 and the water outlet pipe 6 pass through the water mixing device 10 and are sealed and connected to the inner tan...

Embodiment 2

[0044] Such as Figure 7 , Figure 8 As shown, the electric water heater with high hot water output rate provided by this embodiment is basically the same in structure as that of Embodiment 1, the difference lies in:

[0045] 1. A water proportional valve 13 is provided at the water inlet ends of the first area 11 and the second area 12 , and the amount of water entering the first area 11 and the second area 12 is controlled by the water proportional valve 13 . The water proportional valve 13 is connected with the main controller 14 of the electric water heater, and adjusts the water volume according to the instructions issued by the main controller 14 . Referring to Embodiment 1, the main controller 14 of the electric water heater can also collect the temperature of the outlet water through a temperature sensor as a basis for adjustment.

[0046] 2. The water inlet pipe 5 is divided into left and right parts, the water flow of the left part flows directly into the area 2 12...

Embodiment 3

[0050] A method for increasing the hot water output rate of an electric water heater, which is characterized in that the incoming water flow entering the bottom layer of the inner tank of the electric water heater is divided into two parts, one part enters the inner tank, is heated by a heater in the inner tank, and flows from the top of the water outlet pipe Into the outlet pipe, the other part enters the outlet pipe from the bottom of the outlet pipe after being preheated by the bottom water of the liner. In this way, on the premise of ensuring that the water inlet flow rate is not reduced and the water outlet flow rate is sufficiently large, useless mixing of cold and heat is reduced, the hot water output rate is increased, and energy is saved. At the same time, it has its own mixing valve effect, and there is no need for an external mixing valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com