Weighing method, weighing device, unmanned vending cabinet and unmanned vending method

A weighing device and weighing technology are applied in the weighing device, weighing method, unmanned vending container and unmanned vending field, which can solve the problems of increasing the quantity of goods, increasing the weight of the goods, and inconsistency in the quantity, so as to reduce the weight. Probability of discrepancies, the effect of reducing the probability of discrepancies between the calculated quantity of the item and the actual quantity of the item

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

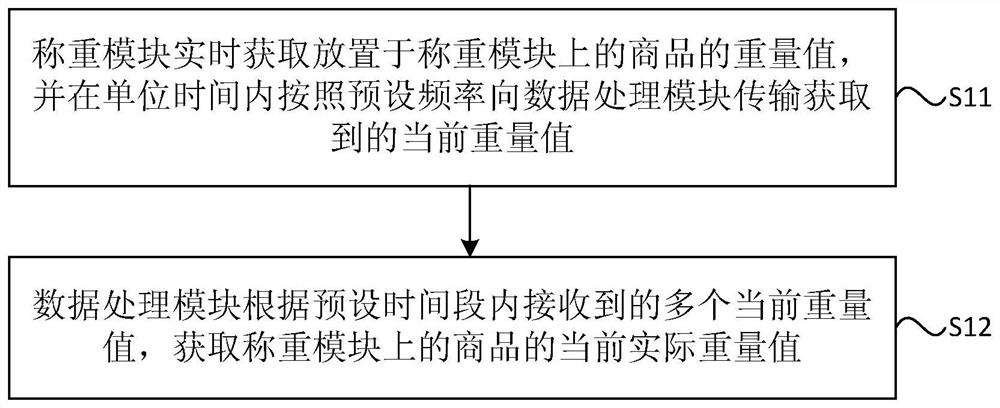

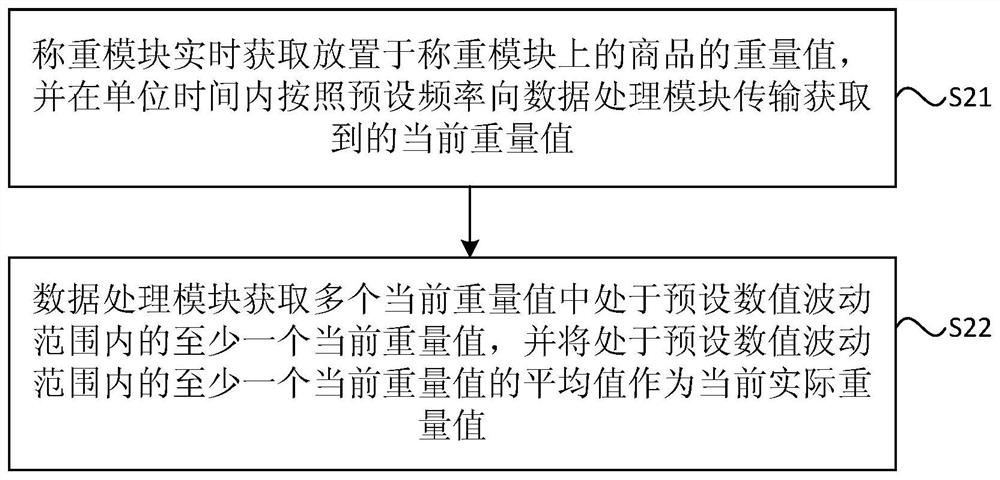

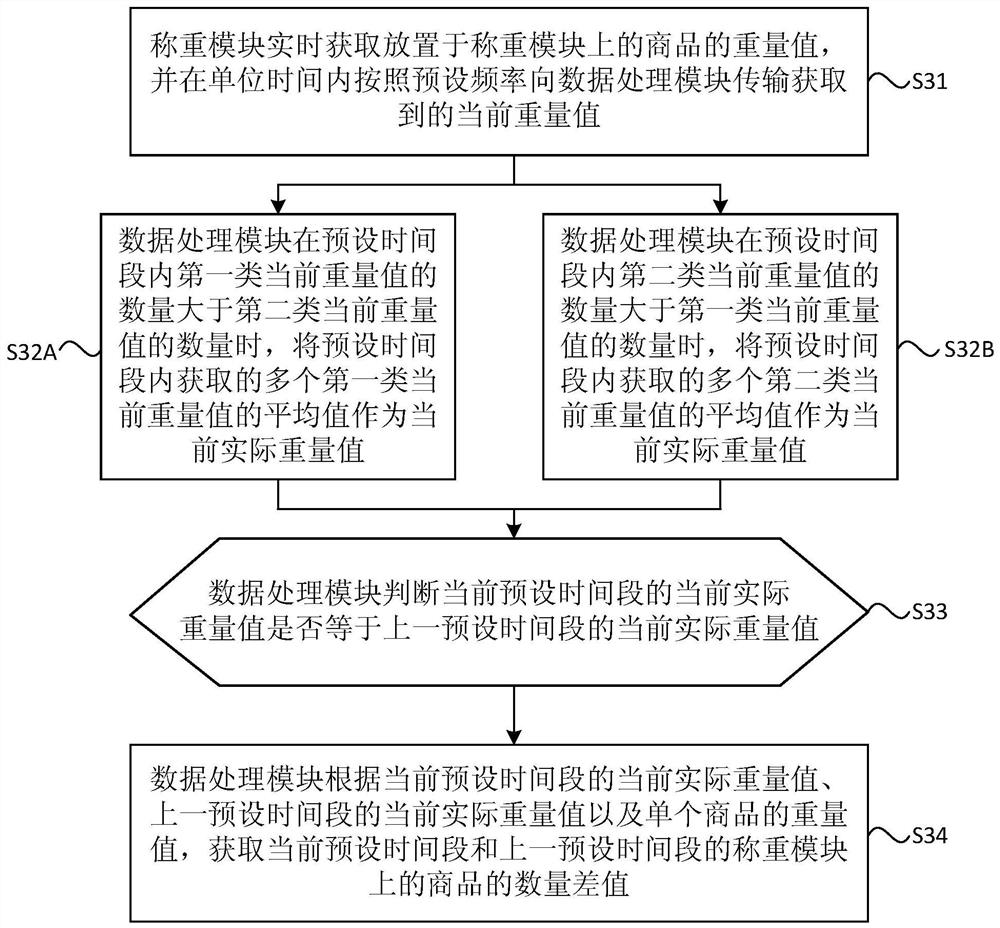

[0063] figure 1 It is a schematic flow chart of a weighing method provided by an embodiment of the present invention. refer to figure 1 , the weighing method includes:

[0064] S11. The weighing module acquires the weight value of the commodity placed on the weighing module in real time, and transmits the acquired current weight value to the data processing module at a preset frequency per unit time.

[0065] Wherein, the weighing module can be a bellows weighing module, a cantilever arm weighing module or a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com