Motor bearing lubrication structure

A lubricating structure, motor bearing technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of accidents, aging of rubber parts, reduction of motor sealing, etc., to achieve balanced temperature and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

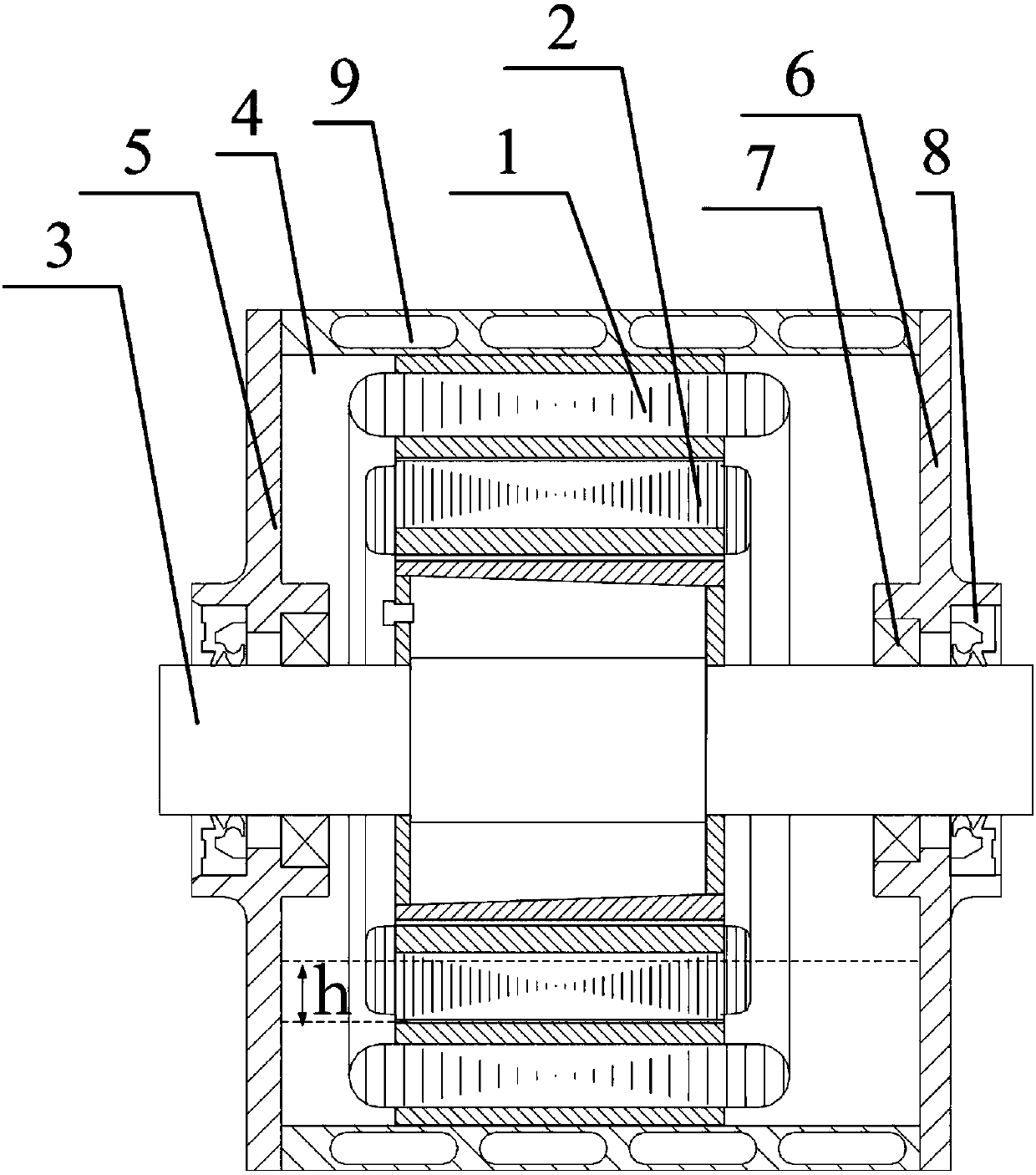

[0017] figure 1 For the motor bearing lubrication structure of the present invention, the motor includes a stator 1, a rotor 2, a motor shaft 3, a motor housing 4, a front end cover 5, a rear end cover 6, a bearing 7, a rotary seal 8 for a motor shaft, and the stator 1 is connected to the motor casing 4, the front end cover 5 and the rear end cover 6 are connected to the motor casing 4, the rotor 2 is connected to the motor shaft 3, and the motor shaft 3 is connected to the front end The cover 5 and the rear end cover 6 are connected through the bearing 7, and the motor shaft is connected with the front end cover 5, the rear end cover 6 and the motor shaft 3 with a rotary seal 8 respectively. The end cover 6 forms a closed space with the motor casing 4 and the rotary seal 8 for the motor shaft, and a certain amount of lubricating medium is injected into the closed space, and the lubricating medium can be a liquid lubricant such as lubricating oil.

[0018] The rotor 2 is part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com