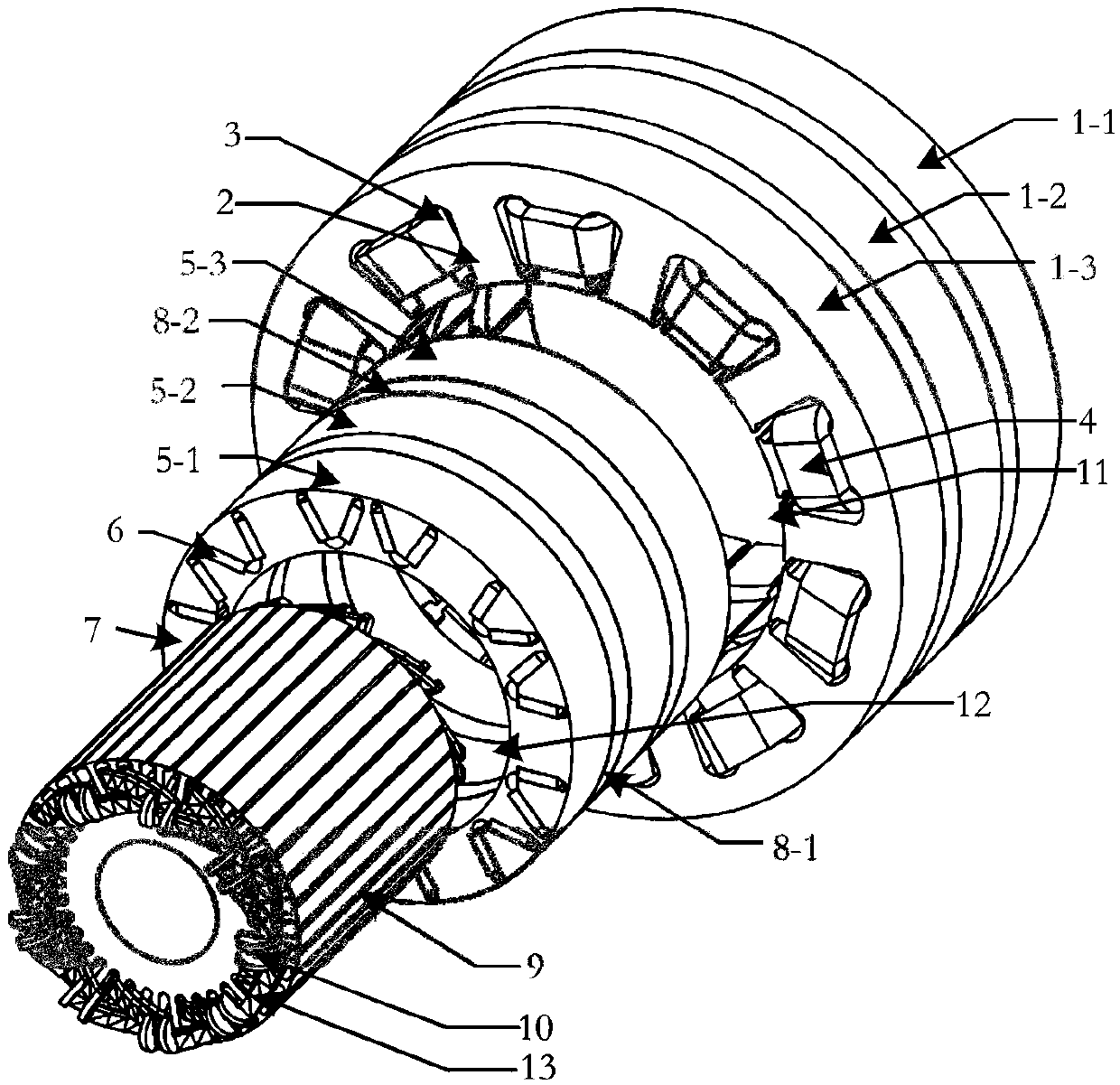

Mixed excitation permanent magnet motor based on three-stage stator axial complementary structure

A hybrid excitation, permanent magnet motor technology, applied in the magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of interference harmonic waste, magnetic circuit asymmetry, interference harmonic utilization, etc. Torque Density and Power Density, Harmonic Distortion Reduction, Effect of Harmonic Distortion Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: If the outer stator of the present invention is not segmented, it is simply referred to as the original "heteropolarity" dual stator topology.

Embodiment 2

[0075] Embodiment 2: If the outer stator of the present invention is not segmented, and the outer stator segments all adopt the form of "multi-winding", it is referred to as the improved "multi-winding" dual-stator topology.

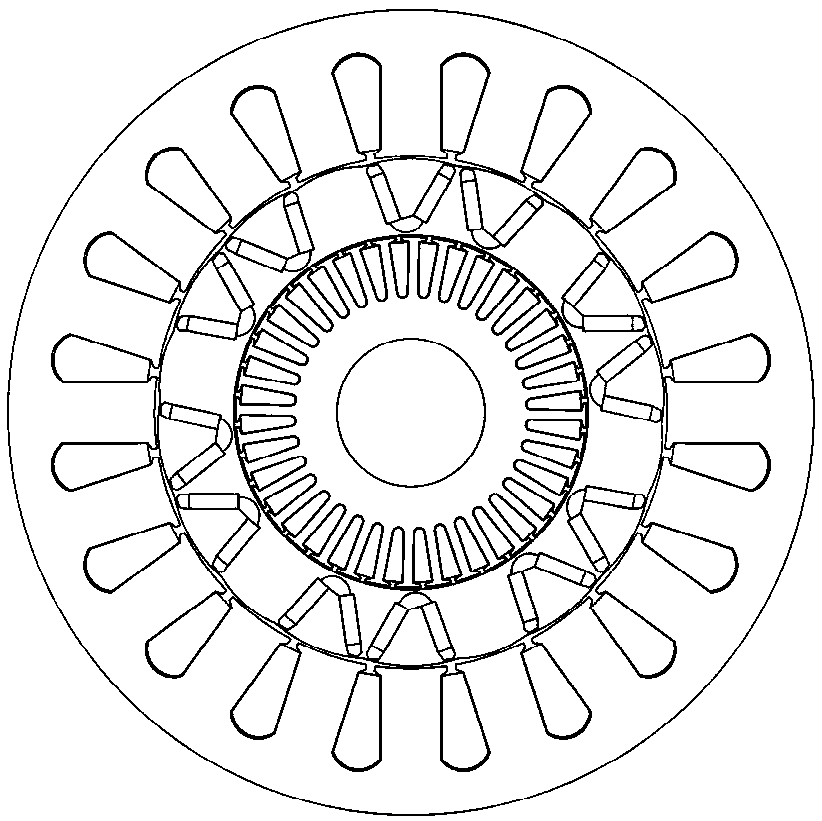

[0076] The above-mentioned original "heteropolarity" dual-stator topology and the improved "multi-winding" dual-stator topology are basically the same as the topological structure diagram of a single stator segment in the present invention, as shown in figure 2 As shown, a cross-sectional topology of a single stator segment of the present invention is shown.

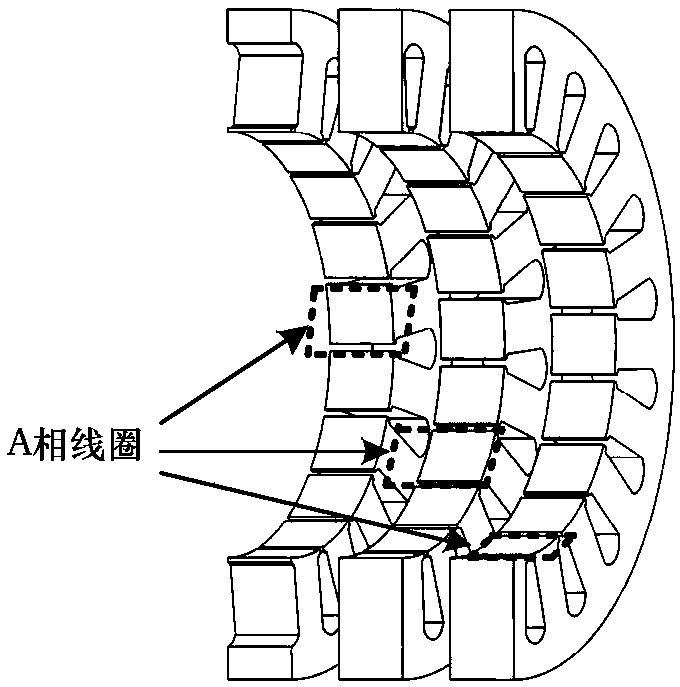

[0077] For the original "heteropolarity" dual-stator topology and the improved "multi-winding" dual-stator topology, the magnetic circuit asymmetry will appear to varying degrees, and this magnetic circuit asymmetry will directly lead to empty phases in each phase. The magnitude of the load back EMF is different, such as Figure 8-1 and Figure 8-2 shown.

[0078] The following theory explains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com