Backflushing filter

A backwashing and filter technology, which is applied in the direction of membrane filter, fixed filter element filter, filtration separation, etc., can solve the problems of limited cleaning effect of suction elements and inability to ensure the cleaning of filter candles, and achieve improved suction results, Avoid maintenance costs and ensure the effectiveness of the filtering function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

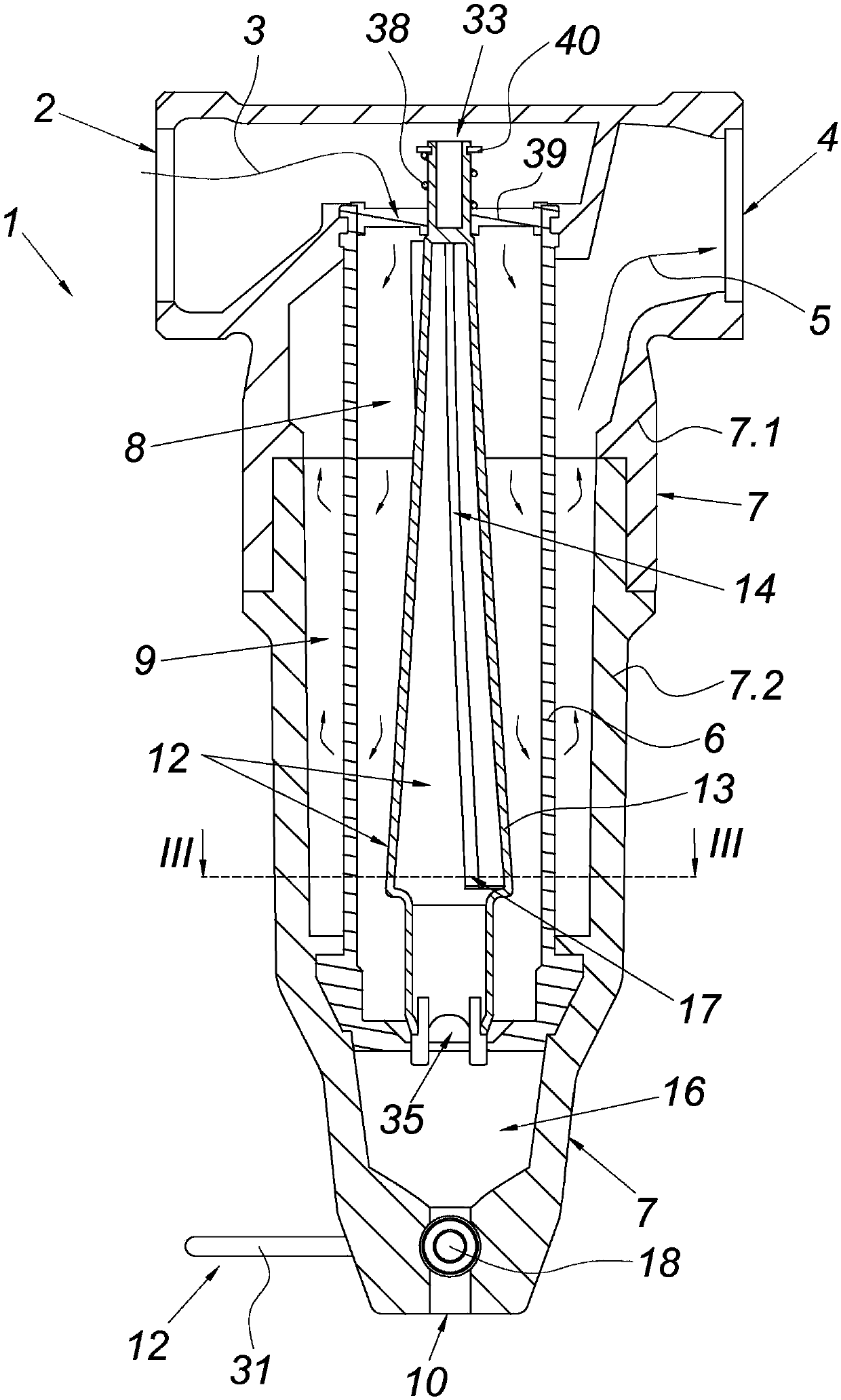

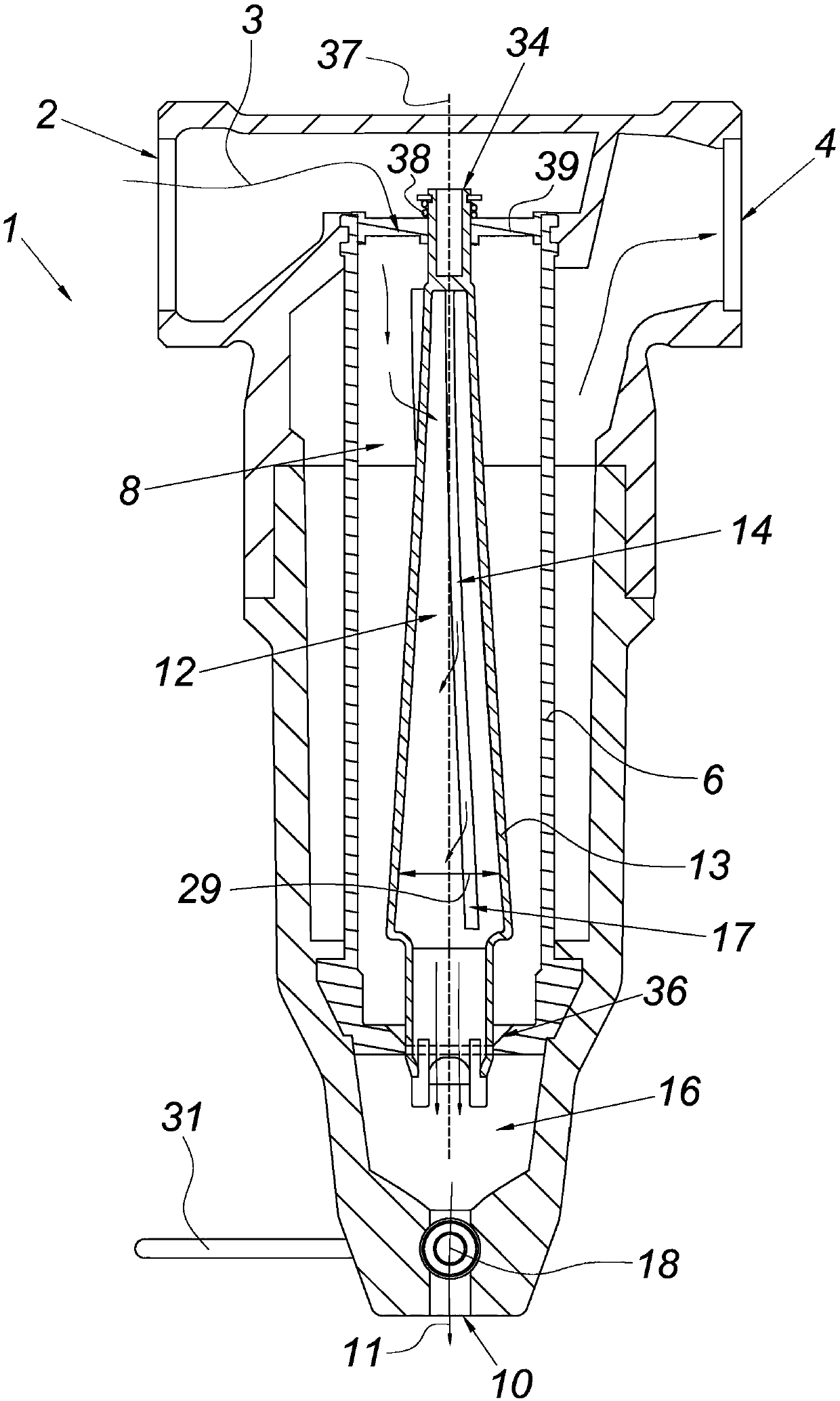

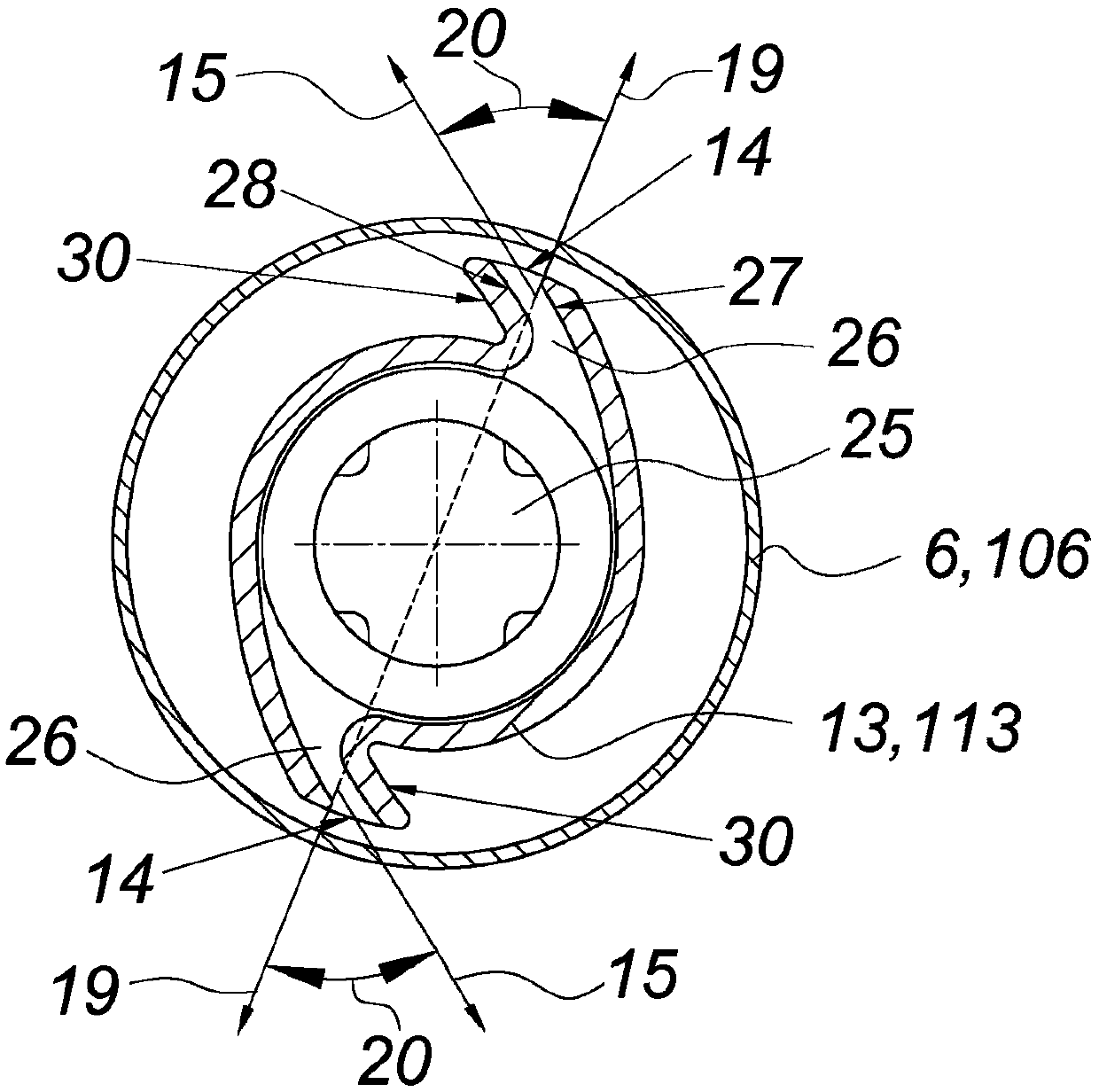

[0031] According to press figure 1 , 2 Backwash filters 1 and 101 shown at , 5 and 6, the inlet 2 for the liquid to be filtered 3, in particular drinking water, and the outlet 4 for the filtered liquid 5 can be seen. In order to filter the liquid 3 , a filter cartridge-shaped filter 6 , 106 is provided in the backwash filter 1 or 101 , which divides the housing 7 of the backwash filter 1 , 101 into the inlet chamber 8 connected to the inlet 2 and the Outlet port 9 connected to outlet 4 . The housing 7 of the backwash filter 1, 101 consists of an upper part 7.1 and a filter cover 7.2 which can be removed from the upper part 7.1.

[0032] according to figure 2 , in order to backwash the backwash filter 1, 101, the backwash filter is designed with an outflow part 10, figure 2 or Image 6 The liquid 11 to be discharged together with possible dirt particles (which are not shown in detail) can be discharged through the outflow 10 . The liquid 11 to be discharged is extracted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com