Seedling tray laying device with one side upper tray and its laying method

A laying device and plate laying technology, which is applied to botany equipment and methods, filling of flower pots, and counting of items shipped through a conveying device, etc., can solve uneven plate placement, large labor demand, and high labor intensity And other problems, to achieve the effect of improving neatness, controlling the number of entries, and accurately entering the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

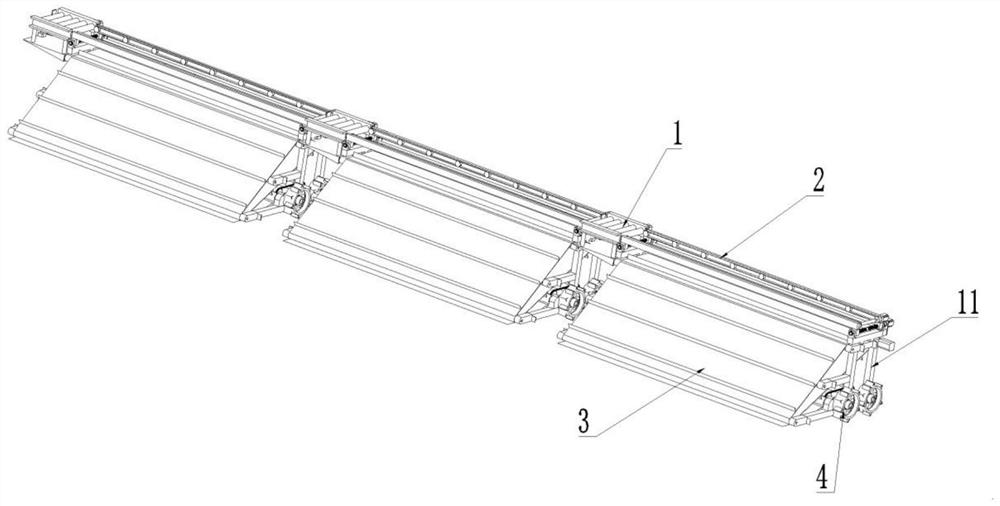

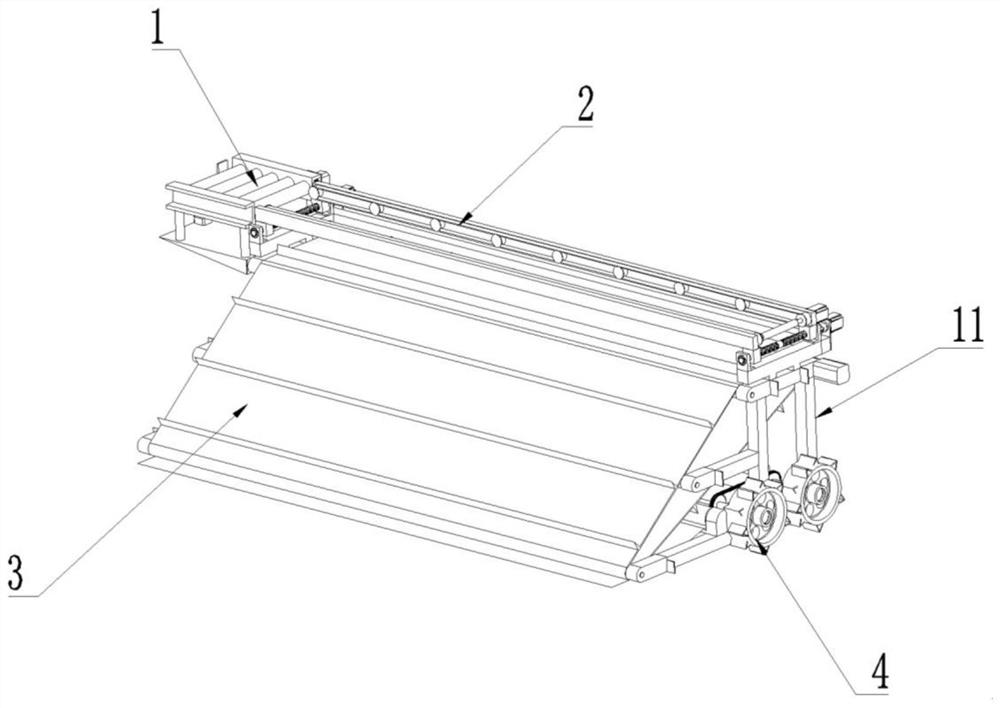

[0039] Such as figure 1 with 2 As shown, a seedling tray laying device with one side upper tray includes n sub-layout modules, n=3. The sub-layout module includes a roller conveying module 1 and a spreader car. The width of the paving vehicle is equal to the width of a ridge of field to be paved. The length of the roller conveyor module 1 is equal to the distance between two adjacent ridges (that is, the width of the groove or road between the ridges).

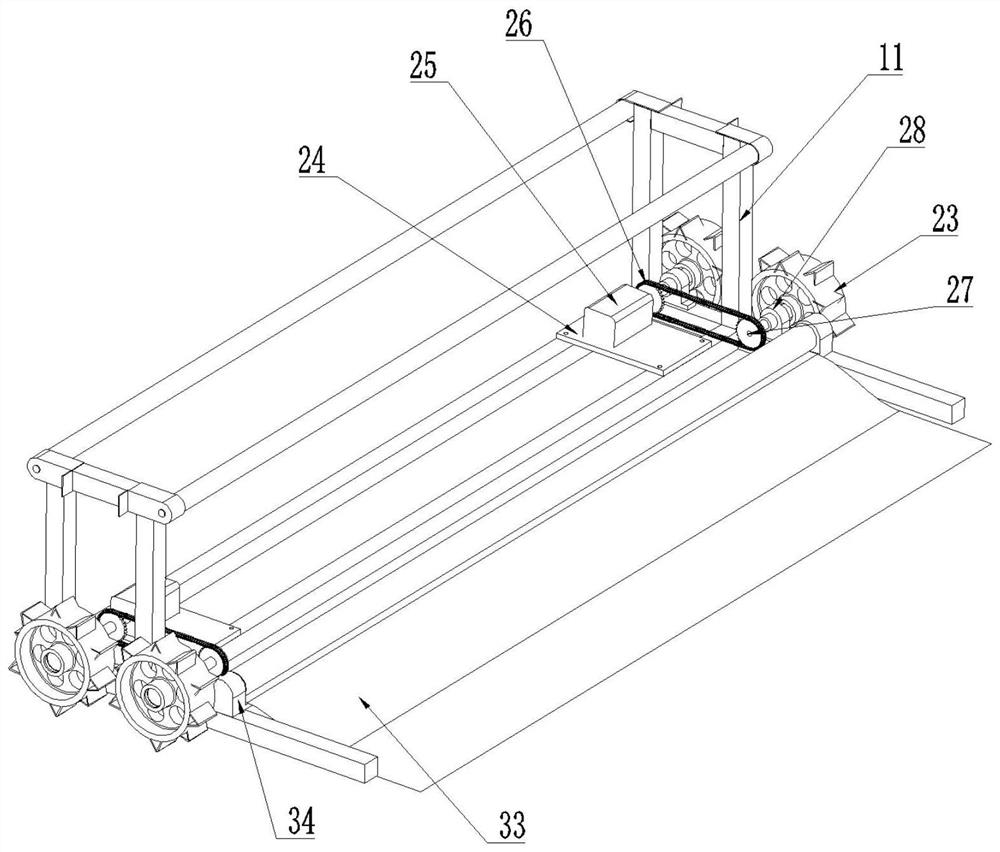

[0040] The plate-laying vehicle includes a horizontal plate-transfer mechanism 2, a vertical plate-laying mechanism 3, a traveling mechanism 4 and a support frame 11. The roller conveyor tray module 1 is fixed on one end of the support frame 11 by the support plate 10, and is used for transporting the seedling raising tray to the tray car. The vertical plate laying mechanism 3 is installed on the support frame 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com