Application of a kind of flotation foaming agent

A foaming agent and flotation technology, used in flotation, solid separation, etc., to achieve the effect of significant foaming effect, increase processing capacity, and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

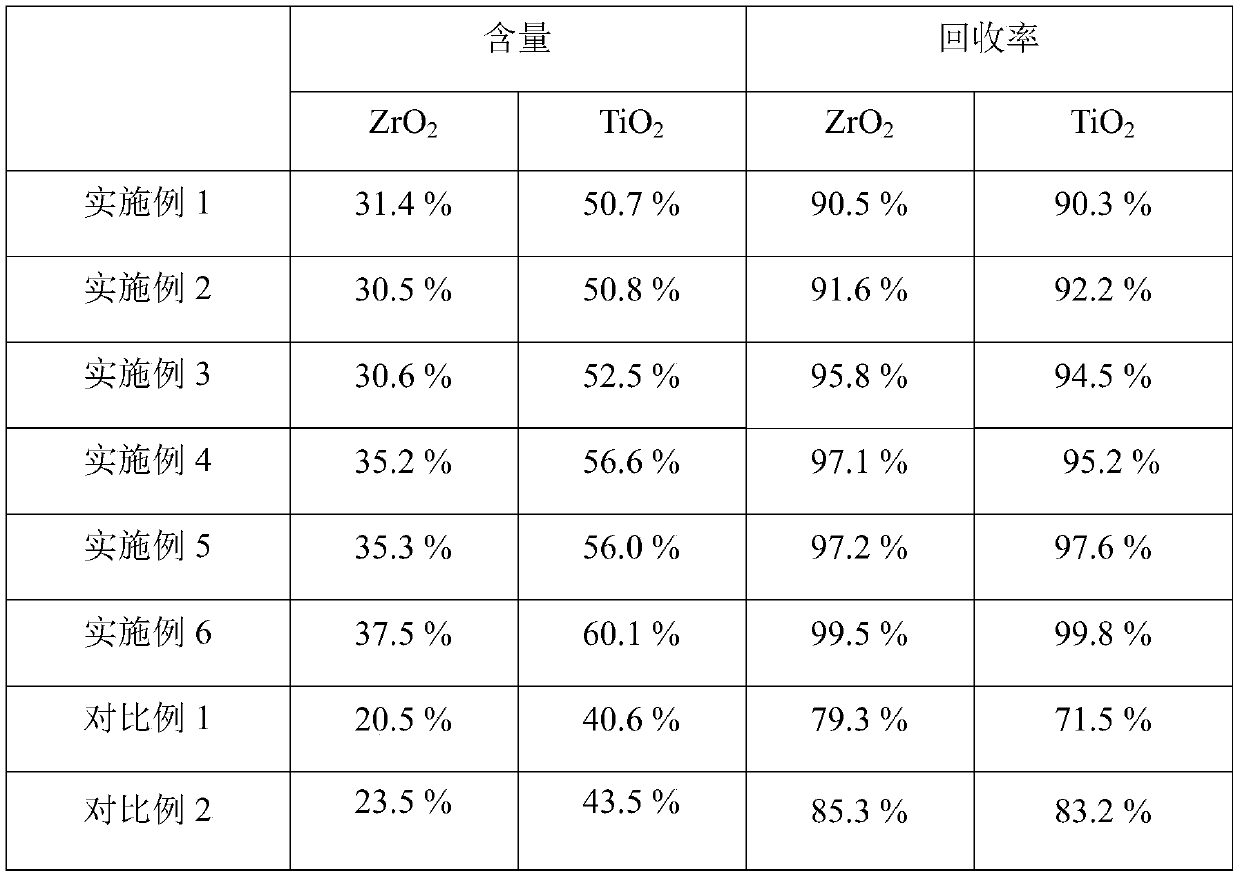

Examples

Embodiment 1

[0024] The flotation of zirconium-titanium ore was carried out with 6501 (namely coconut oil fatty acid diethanolamide) as the foaming agent. The method of use is as follows:

[0025] Add water to minerals (mass ratio 1:1) to make slurry, add water glass, stir for 5 minutes, add soda ash, stir for 5 minutes, add caustic soda, stir for 5 minutes, then add oleic acid, stir for 3 minutes, and finally add 6501.

[0026] Among them, 400 grams of water glass, 200 grams of soda ash, 100 grams of caustic soda, 100 grams of oleic acid and 30 grams of 6501 are added to each ton of minerals.

Embodiment 2

[0028] The flotation of zirconium-titanium ore was carried out with 6501 as the foaming agent. The method of use is as follows:

[0029] Add mineral water (mass ratio 1:2) to make slurry, add water glass, stir for 10 minutes, then add soda ash, stir for 10 minutes, then add caustic soda, stir for 10 minutes, then add oleic acid, stir for 5 minutes, and finally add 6501.

[0030] Among them, 600 grams of water glass, 500 grams of soda ash, 300 grams of caustic soda, 300 grams of oleic acid and 50 grams of 6501 are added to each ton of minerals.

Embodiment 3

[0032] The difference from Example 2 is: 500 grams of water glass, 300 grams of soda ash, 100 grams of caustic soda, 200 grams of oleic acid and 50 grams of the flotation foaming agent are added to each ton of minerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com