Dynamic sorting and carrying automation system

An automated system and dynamic technology, applied in sorting and other directions, can solve problems such as improving production tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

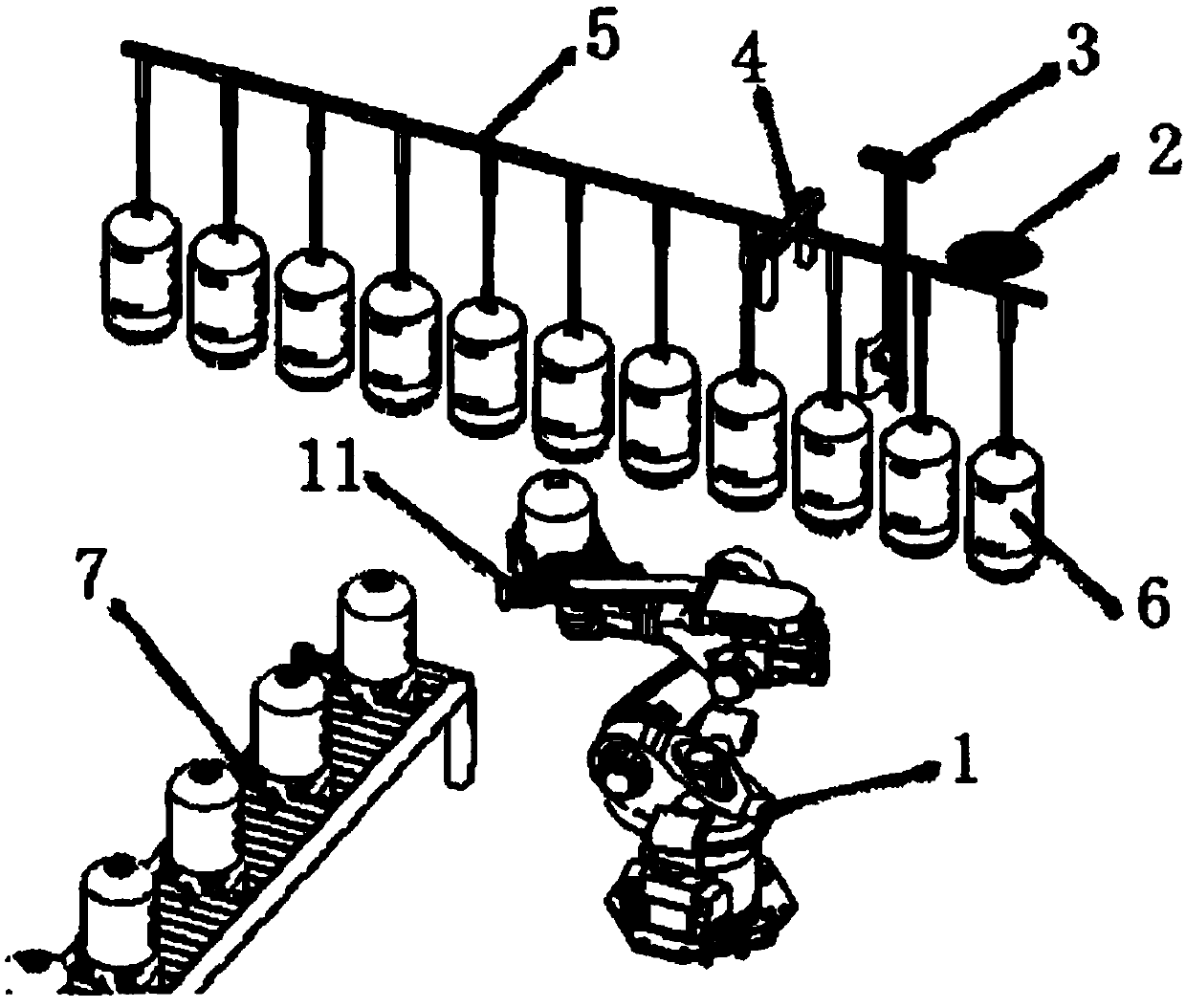

[0018] Such as figure 1 As shown (the arrow line in the figure represents the running direction of the logistics line body 5), the dynamic sorting and handling automation system is mainly composed of a joint robot 1, an accompanying device 2, an industrial vision 3, a photoelectric sensor 4 and a control system; A clamp 11 is installed at the end of the articulated robot 1 for grabbing the product 6; the input shaft of the accompanying device 2 is connected with the moving parts of the logistics line body 5, furthermore, the accompanying device 2 is an encoder, The encoder and the logistics line body 5 can be in frictional contact with each other, or can be toothed connections that mesh with each other, or can be directly connected to the rotary shaft of the encoder through the rotating parts on the logistics line body 5. The linear motion of the line body 5 is converted into the rotary input of the encoder, thereby converting the linear motion speed of the logistics line body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com