Spiral model tear off method

A spiral type and car model technology, which is applied in the direction of turning equipment, turning equipment, metal processing equipment, etc., can solve the problem of not being able to respond to the removal of the inner sleeve or the outer sleeve, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The spiral car model tearing method is used to remove the inner sleeve embedded in the inner wall of the long tube, including the following steps:

[0023] Step 1. Clamp the long tube and drive the long tube to rotate; turn a spiral groove on the inner surface of the inner sleeve;

[0024] Step 2, clamping one end of the inner sleeve, gradually tearing along the groove bottom of the spiral groove, so that the inner sleeve is gradually separated from the long tube.

[0025] Further, the groove bottom wall thickness of the spiral groove is 0.05-0.3mm.

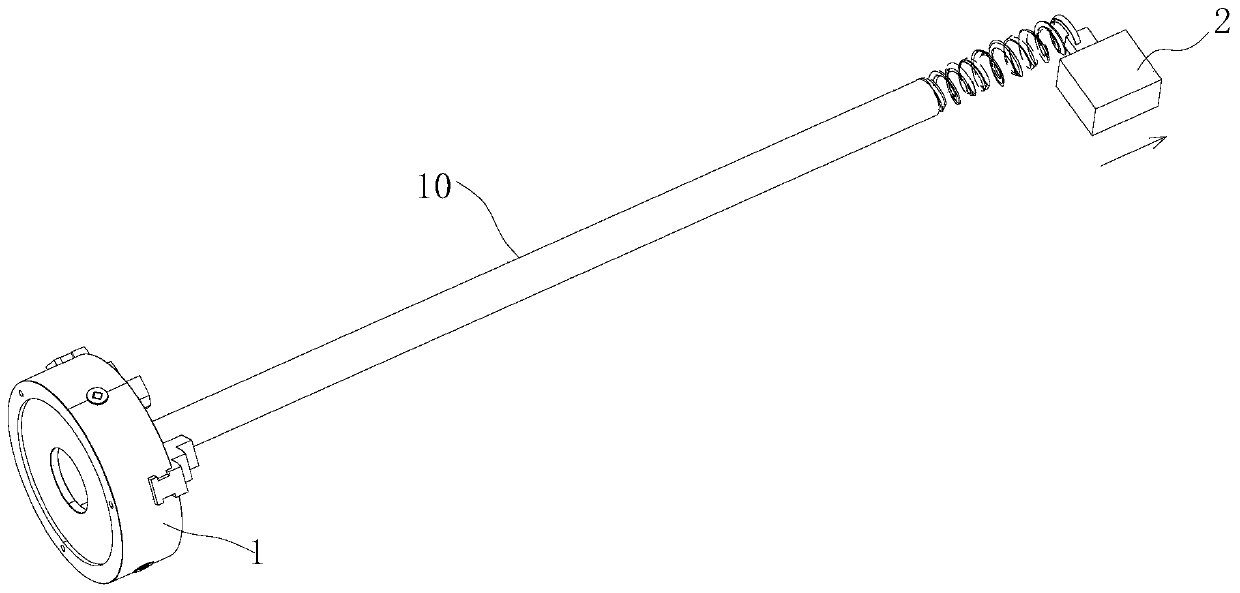

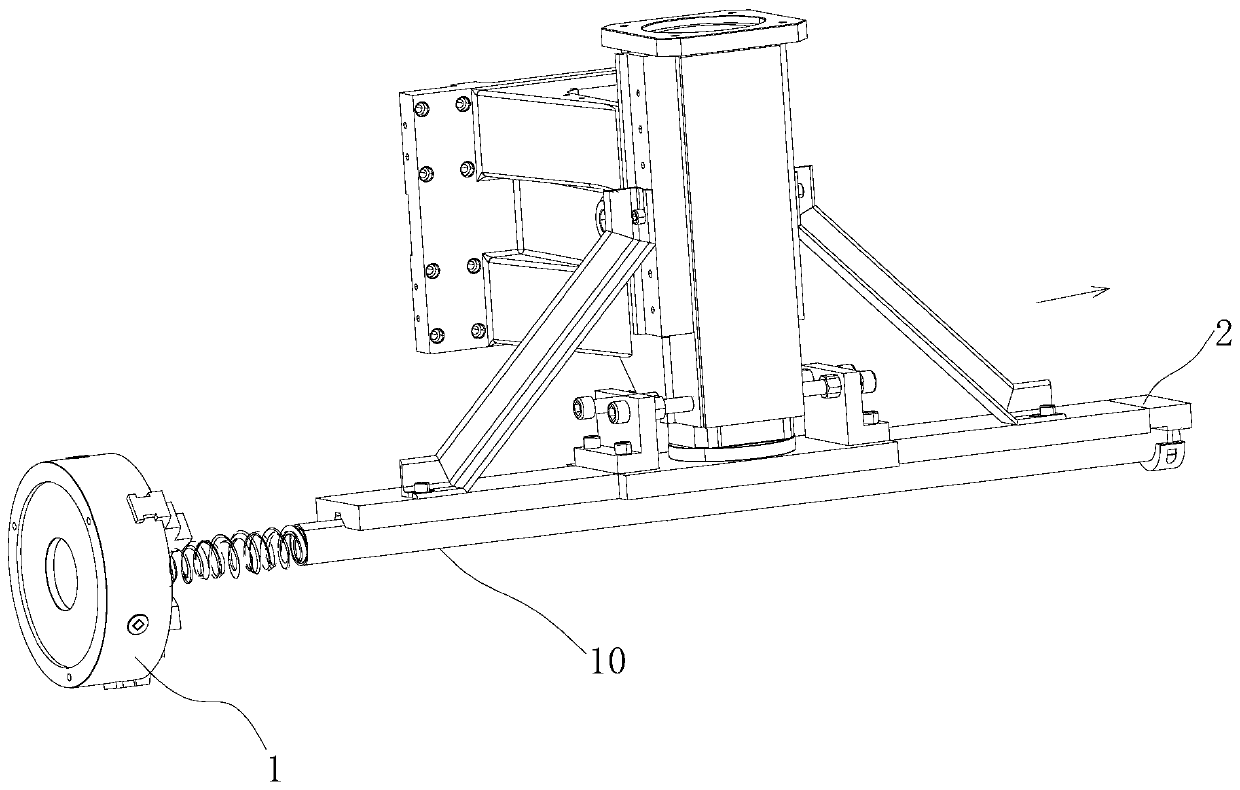

[0026] Further, in the step 1, the three-jaw chuck 1 of the lathe clamps one end of the long tube 10, and the support base or the traveling frame supports the other end of the long tube; the boring tool gradually extends into the long tube for turning. set.

[0027] Further, in the step 2, refer to figure 1 , the clamp 2 clamps the end of the inner sleeve far away from the chuck, and moves to the end far away from the t...

Embodiment 2

[0030] The spiral car model tearing method is used to remove the sleeve sleeved on the outer circle of the long shaft, including the following steps:

[0031] Step 1, clamping the long shaft, and driving the long shaft to rotate; turning a spiral groove on the outer surface of the sleeve;

[0032] Step 2, clamping one end of the shaft sleeve, gradually tearing along the groove bottom of the spiral groove, so that the shaft sleeve is gradually separated from the long axis.

[0033] Further, the groove bottom wall thickness of the spiral groove is 0.05-0.3mm.

[0034] Further, in the step 1, the three-jaw chuck of the lathe clamps one end of the long shaft, and the tailstock tip supports the other end of the long shaft.

[0035] Further, in the step 2, the end of the bushing away from the three-jaw chuck is clamped, and the bushing is gradually torn along the groove bottom of the spiral groove; when the bushing is torn, the long The shaft rotates, and the clamp holding the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com