Mould clamping tool

A technology for clamping tooling and molds, applied in the field of tooling and fixtures, it can solve the problems of low overall stability, small application range, mold shaking, etc., and achieve the effect of maintaining stability, stable and firm position, and stable locking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

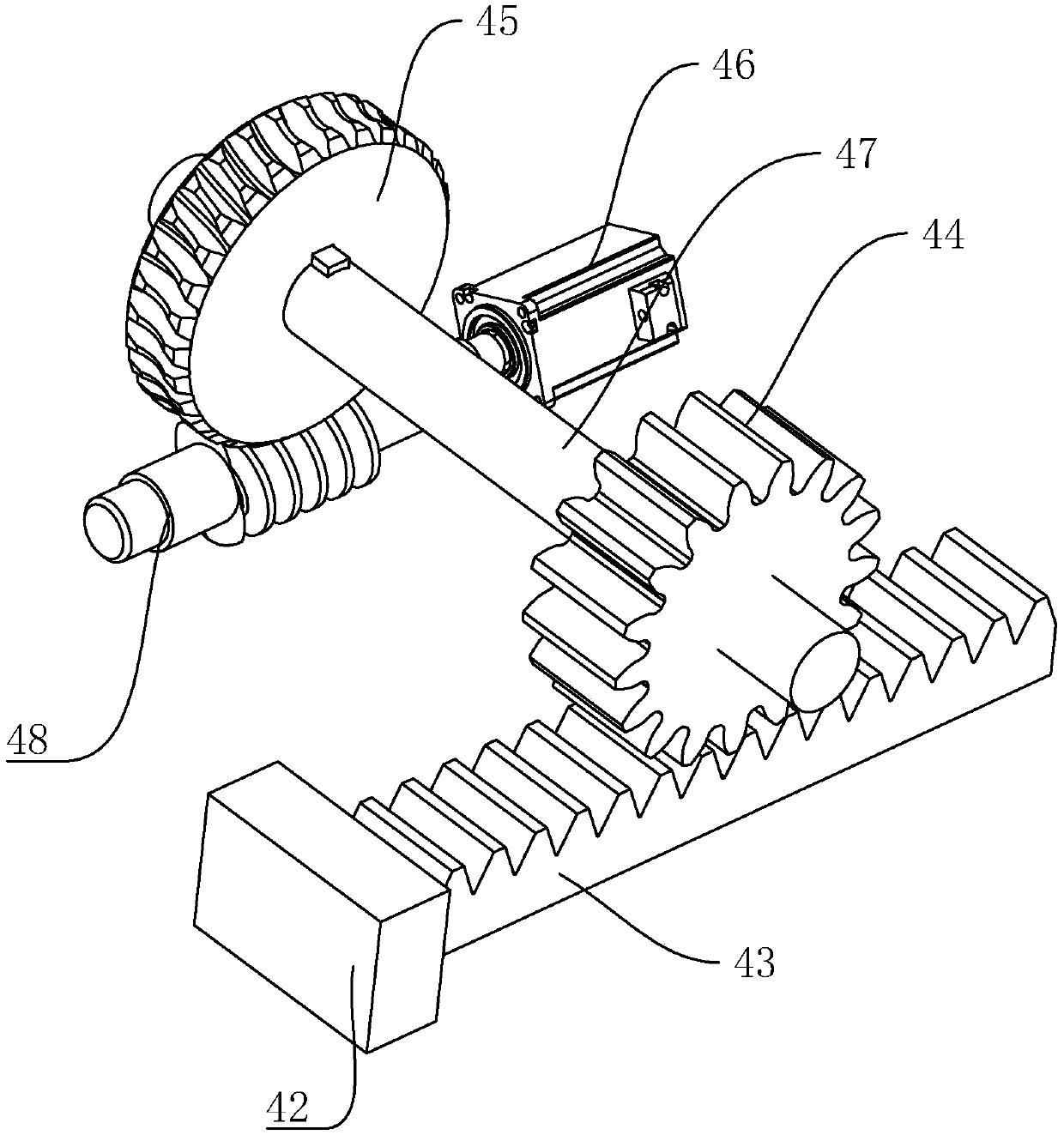

[0033] Embodiment 2, a kind of mold clamping frock, such as image 3 As shown, the difference from Embodiment 1 is that the auxiliary clamping member includes a fixed plate 41 fixed on one side of the bottom plate 36 adjacent to the fixed block 35, and a fixed plate 41 on the other side of the bottom plate 36 facing the fixed plate 41. The rack 43 and the fixed rack 43 are slidably connected to the bottom plate 36 perpendicular to the mold, and the bottom plate 36 is also provided with a driving gear 44 for pushing the fixed rack 43 to slide.

[0034] like image 3 As shown, the drive gear 44 is rotatably connected to the base plate 36 by the rotating shaft 47, the concentric drive worm gear 45 is fixed on the rotating shaft 47, the base plate 36 is also provided with a drive worm 48 and a motor 46, the drive worm 48 meshes with the drive worm gear 45, The motor 46 drives the drive worm 48 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com