Four-in-one water permeable pavement and preparation method thereof

A permeable pavement, integrated technology, applied to the coagulation pavement, roads, roads and other directions paved on site, can solve the problems of uneconomical, difficult to improve the strength of pavement materials, and not environmentally friendly, and achieve the effect of avoiding strength reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preferably, the pre-coated sand is pre-coated sand treated with a hydrophilic modified resin, which is obtained by stirring the sand, hydrophilic modified resin, curing agent and silane coupling agent, and then pulverizing it. The sand described above is sand with a particle size of 60-80 mesh, and the hydrophilic modified resin is E44 or E51 epoxy resin that has undergone hydrophilic modification through Tween 20 or Tween 80, and the curing agent is selected from the grade It is the aliphatic curing agent of 701, 702, 703 or 593, and the described silane coupling agent is selected from KH550 or KH570 silane coupling agent, and the mass ratio of the described curing agent to the hydrophilic modified resin is 3:10, The mortar-sand ratio is 0.5:100, and the usage amount of the silane coupling agent is 10% of the usage amount of the cementitious material. The preparation method of a kind of four-in-one permeable pavement comprises the following steps:

[0040] (1) Evenly ...

Embodiment 1

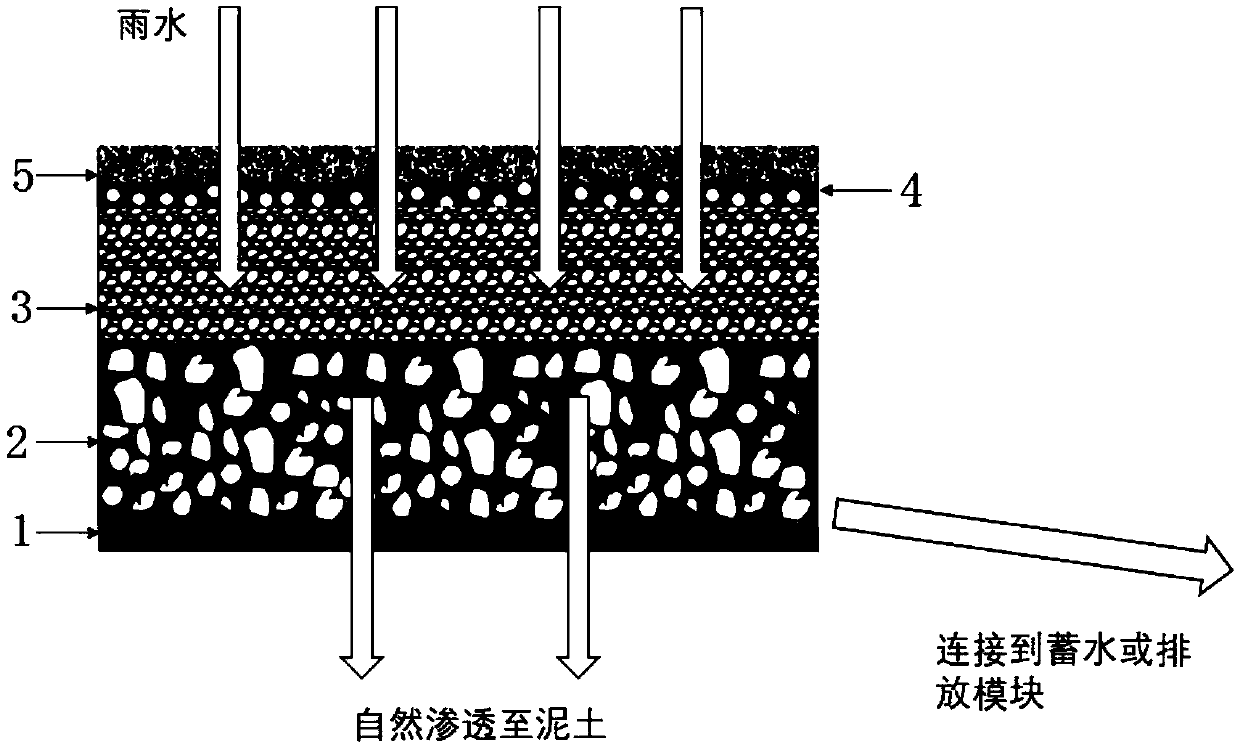

[0049] The four-in-one permeable pavement of the present embodiment, such as figure 1 As shown, it is a continuous integrated structure prepared by sequentially using gravel layer 2, permeable concrete layer 3, permeable mortar layer 4 and resin-based permeable surface layer 5. On-site construction forms.

[0050] In this embodiment, it is preferable to use crushed stones with a particle size of 9.5-19 mm for the crushed stone layer. In this embodiment, the permeable concrete layer preferably adopts a bulk density of 1577kg / m 3 , with an average particle size of 7.4mm and a crushing index of 3.9% basalt. The sand used in the permeable mortar layer in this embodiment is preferably 18-20 mesh single-grade sand, and the cement is Portland 525 cement with a grade of P·I.

[0051] The preparation method of the above-mentioned four-in-one permeable pavement comprises the following steps:

[0052] 1. On the bottom layer of the construction site (such as soil 1), evenly spread a g...

Embodiment 2

[0059] The four-in-one permeable pavement of the present embodiment, such as figure 1 As shown, it is a continuous integrated structure prepared by sequentially using gravel layer 2, permeable concrete layer 3, permeable mortar layer 4 and resin-based permeable surface layer 5. On-site construction forms.

[0060] In this embodiment, it is preferable to use crushed stones with a particle size of 9.5-19 mm for the crushed stone layer. In this embodiment, the permeable concrete layer preferably adopts a bulk density of 1577kg / m 3 , with an average particle size of 7.4mm and a crushing index of 3.9% basalt. The sand used in the permeable mortar layer in this embodiment is preferably 18-20 mesh single-grade sand, and the cement is Portland 525 cement with a grade of P·I.

[0061] 1. On the bottom layer of the construction site (such as soil), evenly spread a gravel layer with a particle size range of 9.5-19mm, and then evenly spread a well-mixed permeable concrete layer on top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap