Brick block conveying rack for wall construction

A technology for conveying racks and bricks, applied in the field of conveying racks, which can solve the problems of spending a lot of time moving bricks, easily falling off the racks and being injured, and affecting the efficiency of wall-building, so as to achieve high work efficiency, prevent injuries, and ensure safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

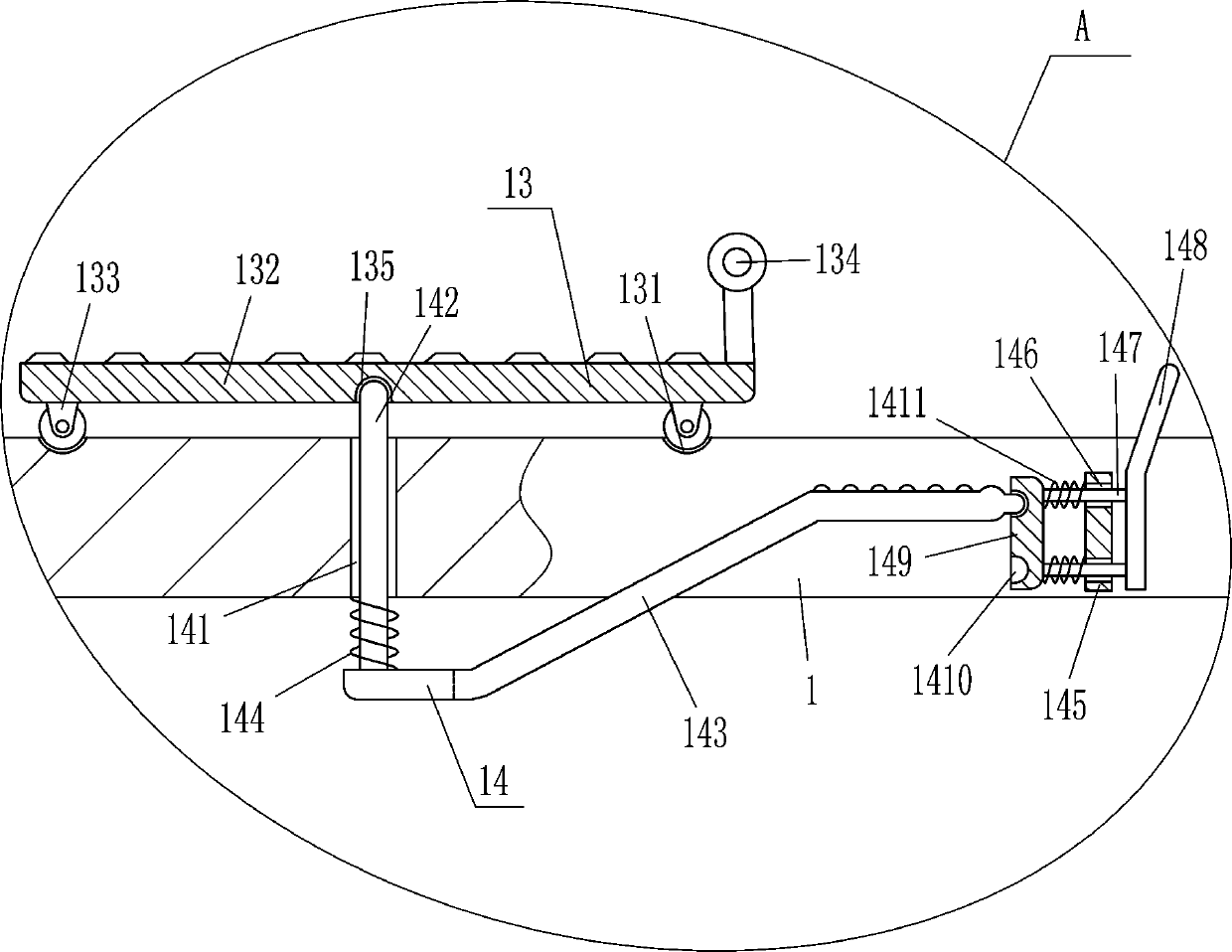

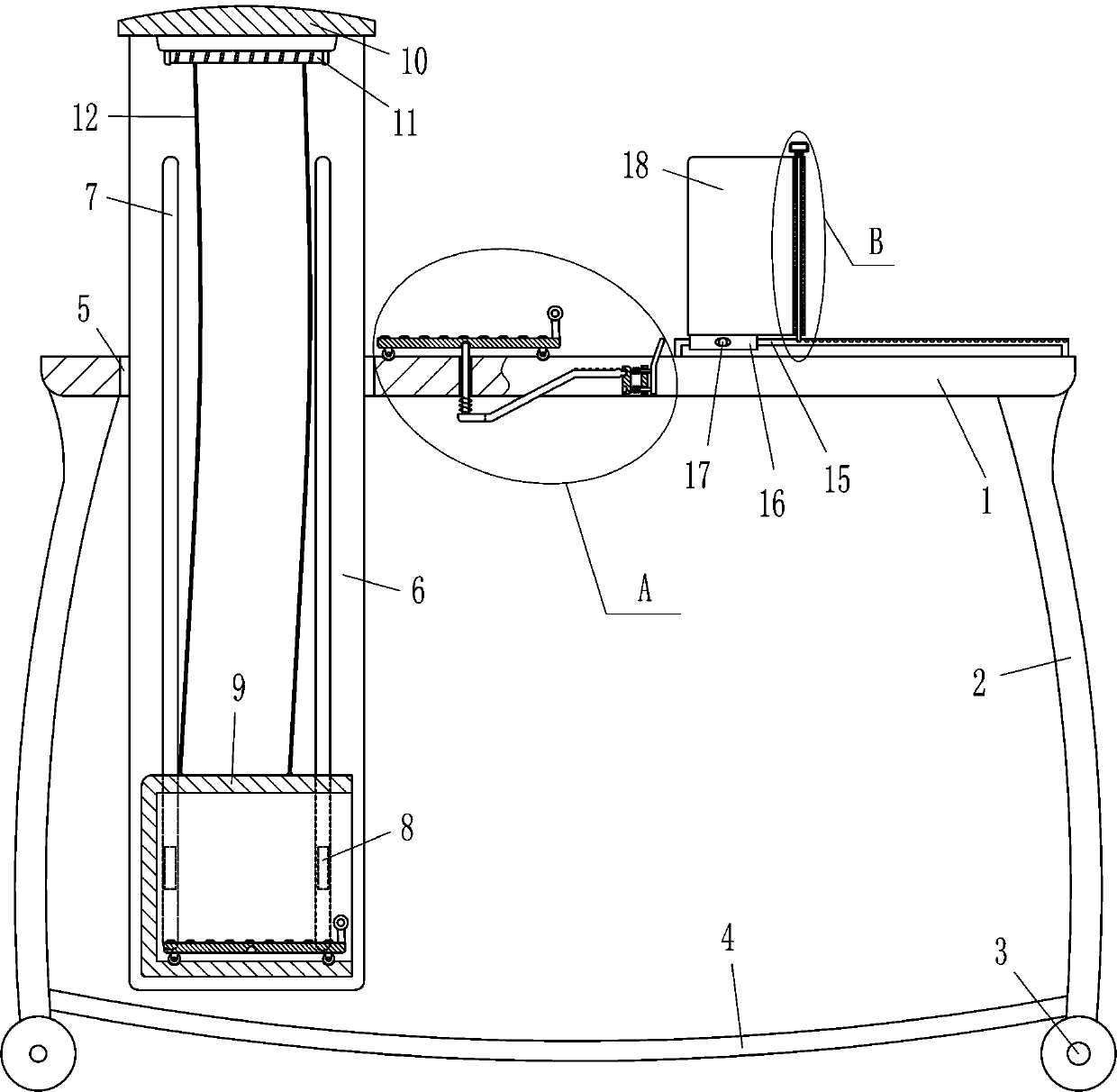

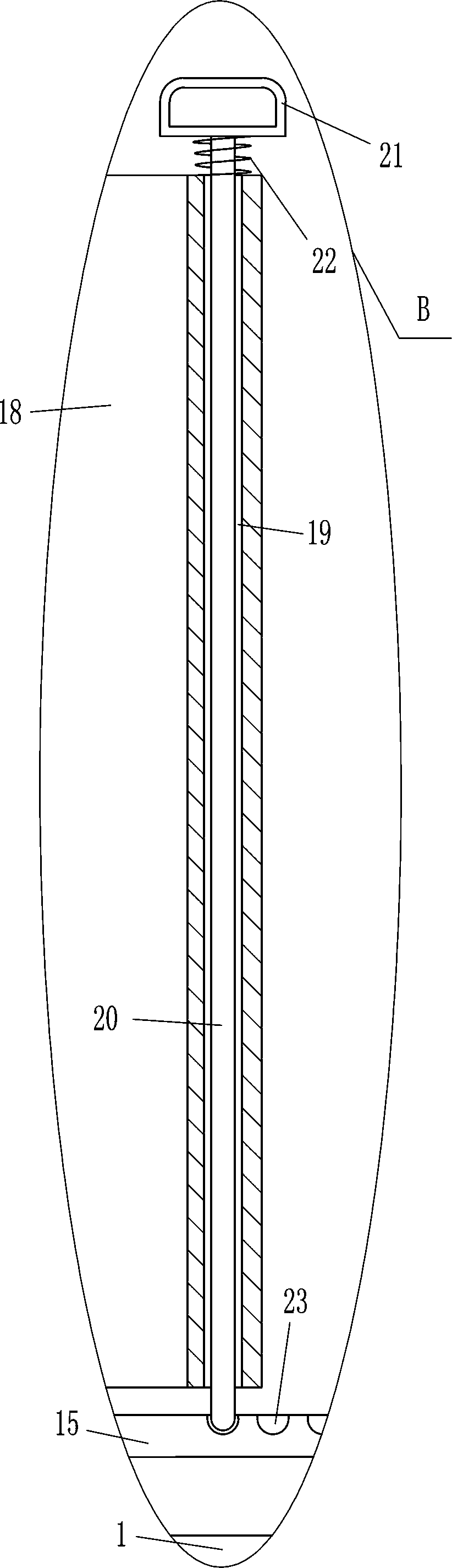

[0016] A kind of brick conveyor rack for building walls, such as Figure 1-2 As shown, it includes a horizontal plate 1, a leg 2, a universal wheel 3, a connecting rod 4, a vertical plate 6, a vertical slider 8, a u-shaped frame 9, a fixed plate 10, a winch 11, a wire rope 12 and a moving device 13 , the left and right sides of the bottom of the horizontal plate 1 are symmetrically installed with outriggers 2, the horizontal plate 1 is connected with the outriggers 2 through bolt connection, and there are two universal wheels 3, which are respectively installed at the bottom ends of the left and right outriggers 2 A connecting rod 4 is fixedly connected between the lower parts of the inner sides of the left and right legs 2, the legs 2 are connected to the connecting rod 4 by means of bolts, the left side of the horizontal plate 1 has an opening 5, and the rear side of the opening 5 is fixed with a Riser 6, vertical chute 7 is arranged on the left and right sides of the lower ...

Embodiment 2

[0018] A kind of brick conveyor rack for building walls, such as Figure 1-2 As shown, it includes a horizontal plate 1, a leg 2, a universal wheel 3, a connecting rod 4, a vertical plate 6, a vertical slider 8, a u-shaped frame 9, a fixed plate 10, a winch 11, a wire rope 12 and a moving device 13 , the left and right sides of the bottom of the horizontal plate 1 are symmetrically equipped with outriggers 2, and there are two universal wheels 3, which are respectively installed at the bottom ends of the left and right outriggers 2, and are fixedly connected between the lower parts of the inner sides of the left and right outriggers 2 There is a connecting rod 4, an opening 5 is opened on the left side of the horizontal plate 1, a vertical plate 6 is fixedly connected to the rear side of the opening 5, and vertical chute 7 is symmetrically opened on the left and right sides of the front side of the vertical plate 6, and the vertical chute The sliding type in 7 is provided with...

Embodiment 3

[0021] A kind of brick conveyor rack for building walls, such as Figure 1-2 As shown, it includes a horizontal plate 1, a leg 2, a universal wheel 3, a connecting rod 4, a vertical plate 6, a vertical slider 8, a u-shaped frame 9, a fixed plate 10, a winch 11, a wire rope 12 and a moving device 13 , the left and right sides of the bottom of the horizontal plate 1 are symmetrically equipped with outriggers 2, and there are two universal wheels 3, which are respectively installed at the bottom ends of the left and right outriggers 2, and are fixedly connected between the lower parts of the inner sides of the left and right outriggers 2 There is a connecting rod 4, an opening 5 is opened on the left side of the horizontal plate 1, a vertical plate 6 is fixedly connected to the rear side of the opening 5, and vertical chute 7 is symmetrically opened on the left and right sides of the front side of the vertical plate 6, and the vertical chute The sliding type in 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com