Compensative connector for drilling fluid pulse generator for intelligent well drilling system

A technology of pulse generator and connector, which is applied in the direction of connection, wellbore/well parts, vibration generating device, etc., can solve the difficult problems of mud generator length consistency, assembly error, processing error, etc., and achieve compact structure and easy assembly Simple, avoid virtual connection and disconnection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

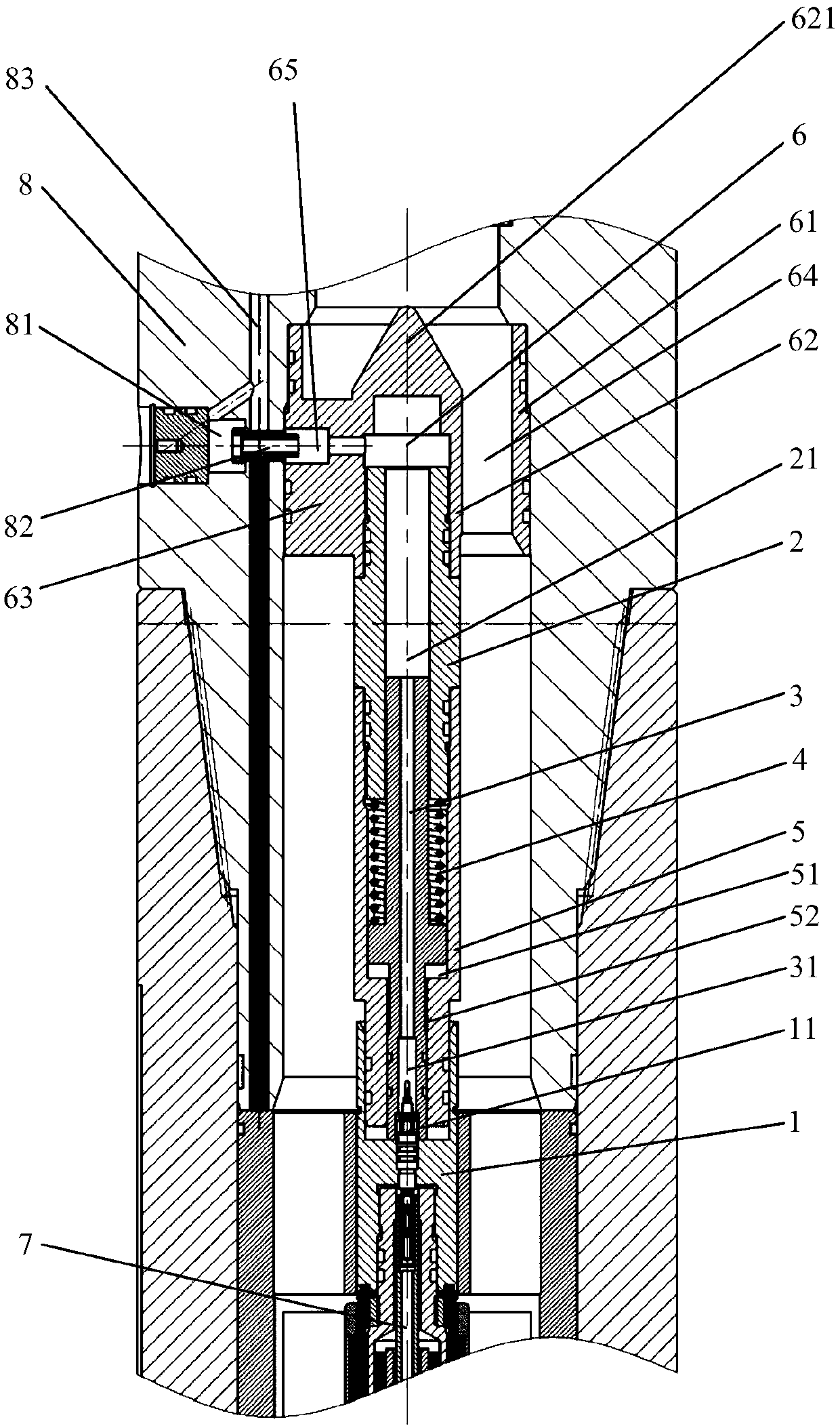

[0011] Such as figure 1 As shown, the compensation connector used in the drilling fluid pulse generator of the intelligent drilling system of the present invention includes a connector seat 1, a coaxial connector 11, a sliding sleeve 2, a sliding rod 3, a spring 4, a spring barrel 5, and a conversion sleeve 6. The connector seat 1 is installed on the upper end of the mud generator 7 and is matched with the lower end of the spring barrel 5 at the same time, and a coaxial connector 11 is installed inside it. The lower end of the coaxial connector 11 is connected to the pulse control driving circuit system inside the mud generator 7 through wires. The spring barrel 5 and the sliding sleeve 2 are screwed together, a large slideway 51 is formed between the cavity in the spring barrel 5 and the sliding sleeve 2, and a first hole-shaped slideway is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com