Method of using anaerobic methane-oxidizing bacteria to improve gas permeability of coal seam

An anaerobic methane, oxidizing bacteria technology, applied in earth-moving drilling, wellbore/well components, production fluids, etc., can solve problems such as gas gushing, hidden safety hazards, hole stability and porosity impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] A kind of coal bed anti-permeability method utilizing anaerobic methane oxidizing bacteria of the present invention, its preferred embodiment is:

[0014] The characteristics of the hole described in step S101 are: the extending direction of the hole should be downward, and the axis of the hole should maintain an inclination angle of 3 / 1000 with the horizontal plane of the hole, and the hole wall should be flat, and the part of the hole wall that is protruding or depressed The maximum distance from the axis of the hole should not exceed 1.5cm, the diameter of the hole should be 100mm, and the length of the hole should be determined according to the actual engineering needs.

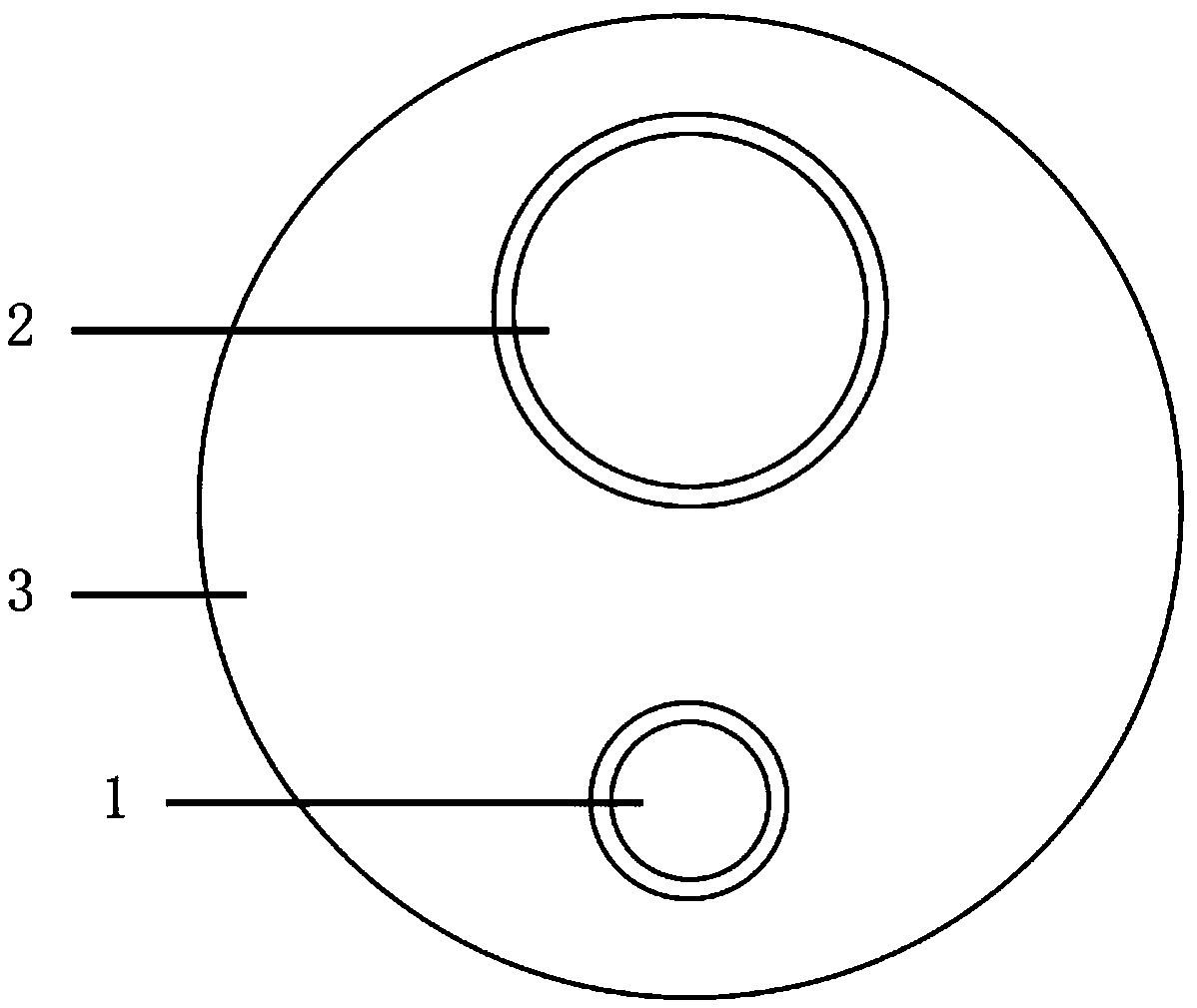

[0015] The piping arrangement described in step S103 is characterized by including a bacteria injection pipe 1 and an air extraction pipe 2 . The characteristic of bacteria injection tube 1 is that an end stretching towards the bottom of the hole should be 20-25cm away from the bottom of the hole, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap