A pneumatic all-inclusive ball valve

A technology of wrapping balls and spherical shells, applied in the field of pneumatic all-inclusive ball valves, which can solve the problems of inconvenient disassembly and repair of pneumatic all-inclusive ball valves and low accuracy, and achieve the effect of easy repair of the valve interior and high flow adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

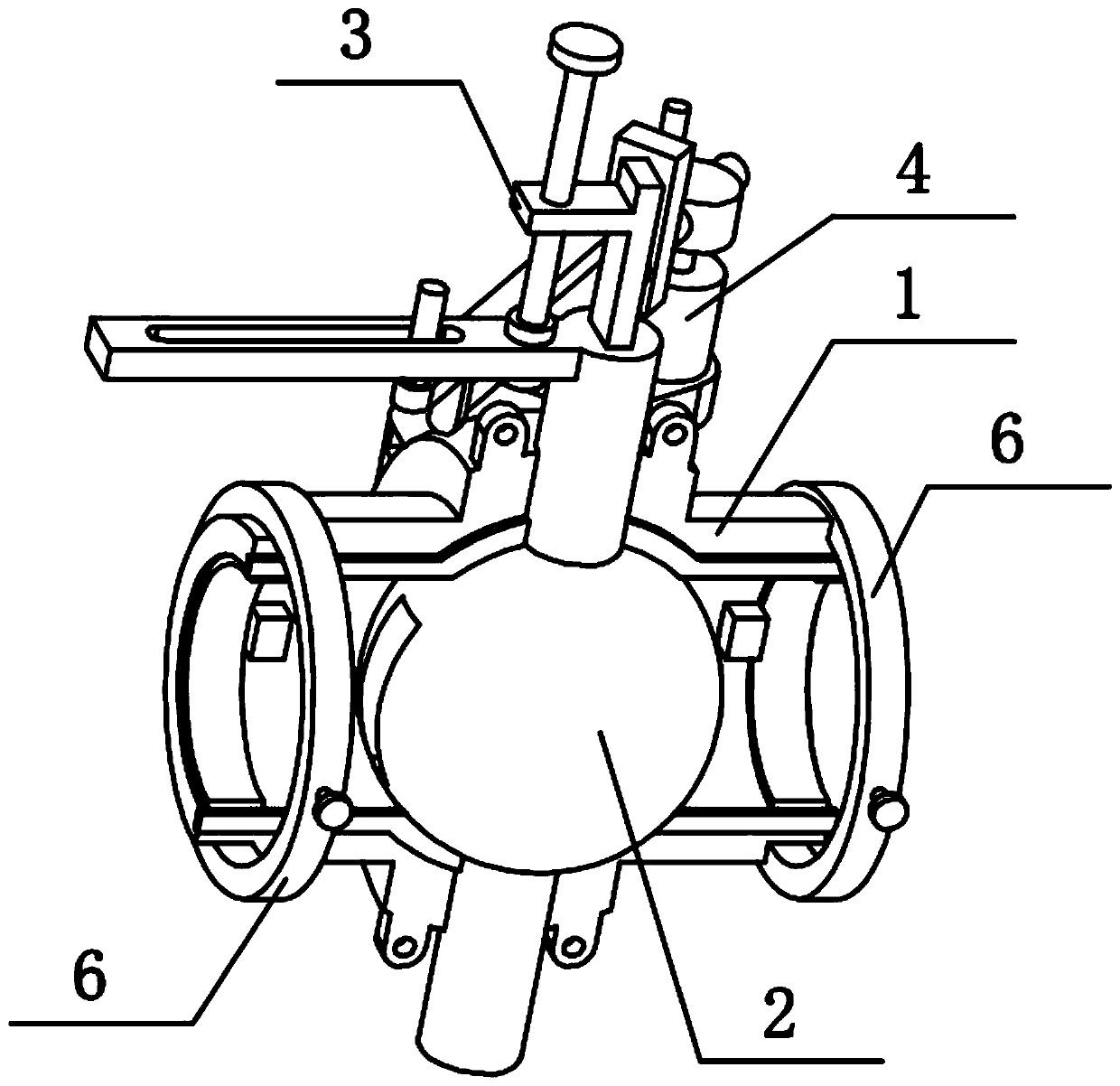

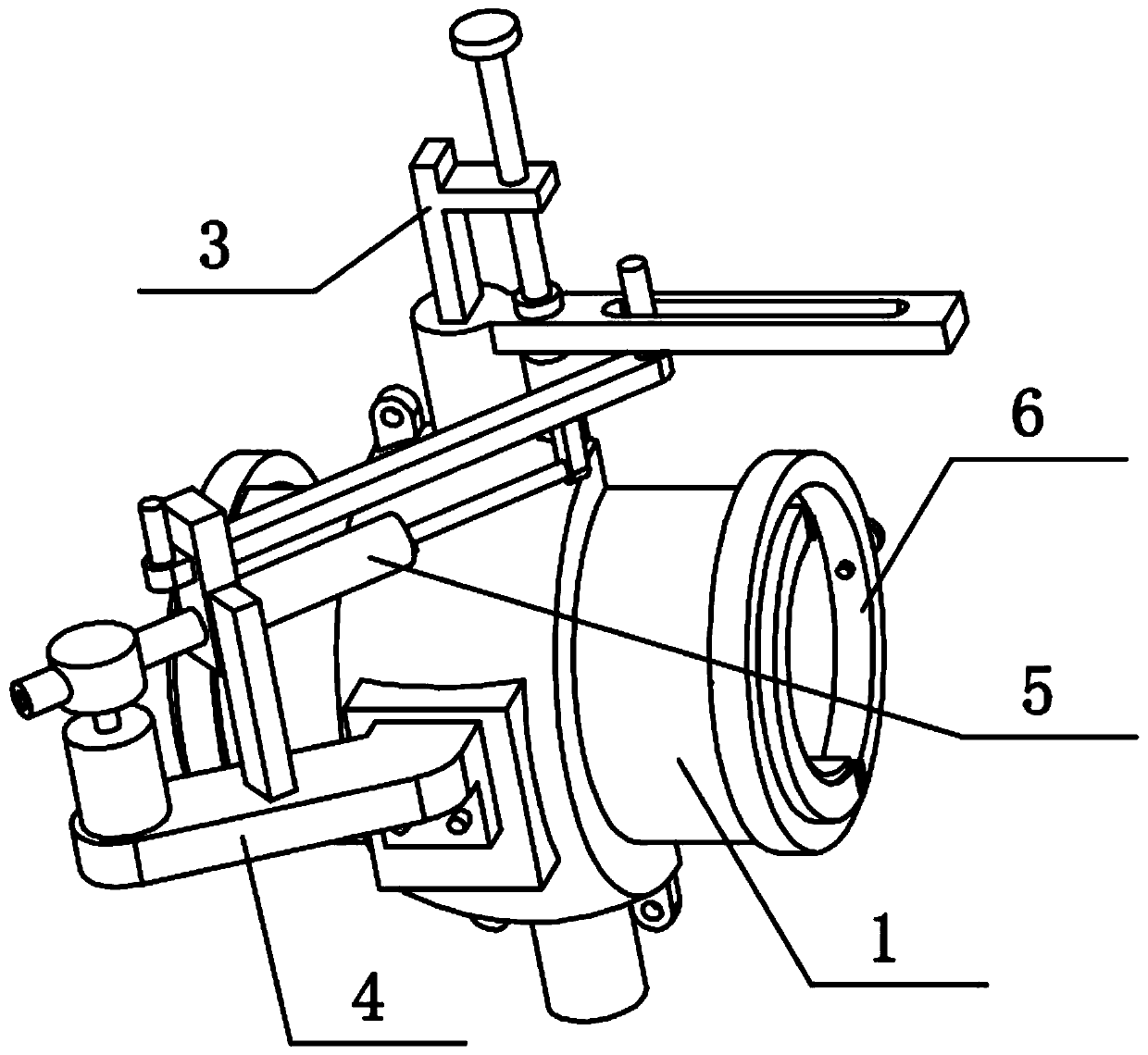

[0031] Combine below Figure 1-12 To illustrate this embodiment, the present invention relates to a ball valve, more specifically a pneumatic all-inclusive ball valve, including a housing 1, a rotating ball 2, a gate assembly 3, a pneumatic assembly 4, a telescopic assembly 5 and a ferrule 6. The invention can drive the rotating ball 2 to rotate through the pneumatic assembly 4, thereby controlling the opening and closing of the valve, and the gate assembly 3 can manually adjust the flow rate of the valve again, and the flow adjustment accuracy is high; when the inside of the valve needs to be repaired, the two shells 1 Easy to separate for easy repair of valve interior.

[0032] There are two shells 1 front and back, the two shells 1 are buckled and fixed together, the gate assembly 3 is rotatably connected between the two shells 1, the gate assembly 3 is arranged on the upper end of the rotating ball 2, and the pneumatic assembly 4 is fixed Connected to one of the shells 1,...

specific Embodiment approach 2

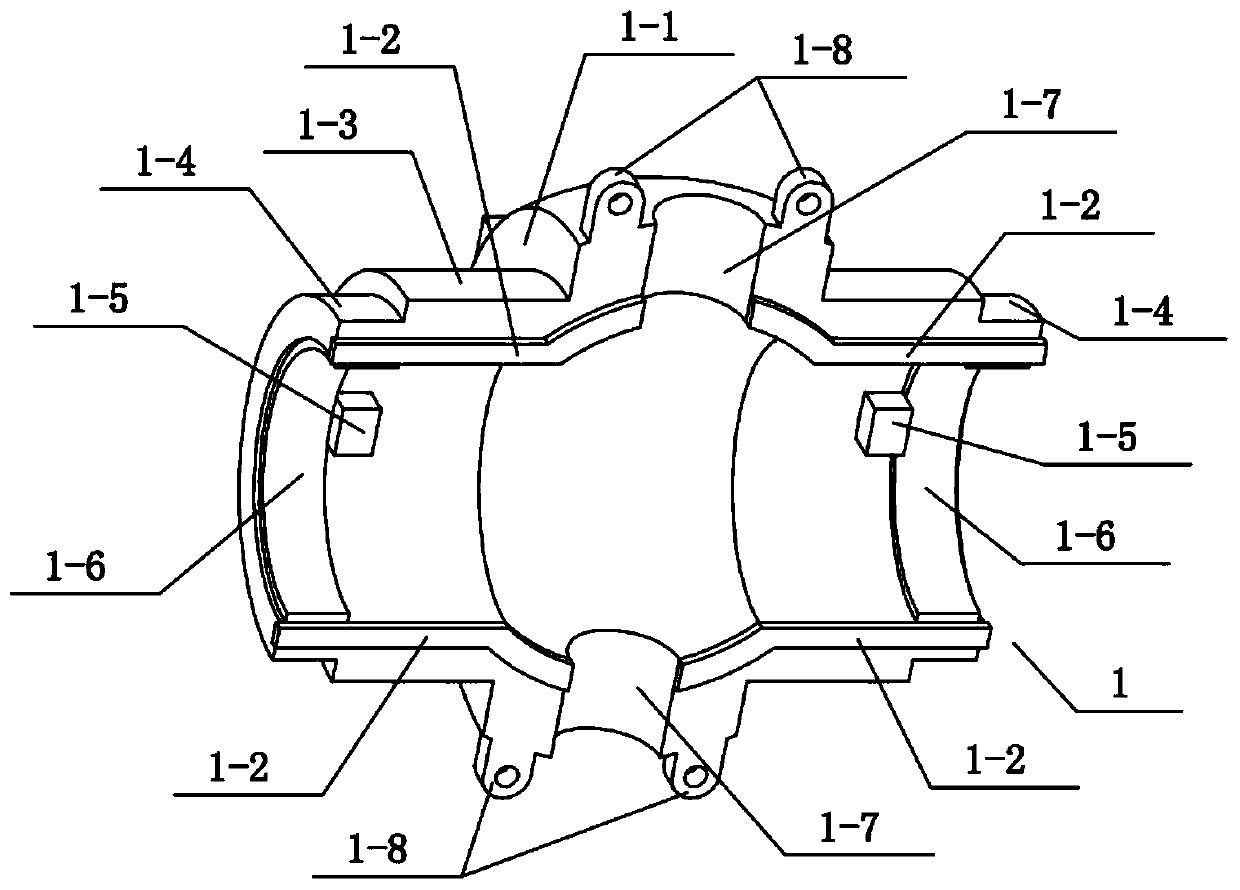

[0034] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain Embodiment 1, the housing 1 includes a spherical shell 1-1, a sealing strip 1-2, a semicircular pipe 1-3, an annular groove 1-4, and a limiting post 1- 5. Internal thread 1-6, shaft hole 1-7, jack seat 1-8 and square seat 1-9, the left and right ends of spherical shell 1-1 are fixedly connected with semicircular pipe 1-3, two semicircular pipes The upper and lower ends of 1-3 are bonded with sealing strips 1-2, the upper and lower ends of spherical shell 1-1 are fixedly connected with two jack seats 1-8, and the upper and lower ends of spherical shell 1-1 are A shaft hole 1-7 is provided, a square seat 1-9 is provided on the outside of the spherical shell 1-1, an annular groove 1-4 is provided on the outside of the two semicircular tubes 1-3, and an annular groove 1-4 is provided on the inside of the two semicircular tubes 1-3. Both are provided with internal threads 1-6, and the i...

specific Embodiment approach 3

[0036] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating ball 2 includes a round ball 2-1, an upper rotating shaft 2-2, a gate chute 2-3, a sliding orifice plate 2-4, a sliding Hole 2-5, water channel 2-6 and lower rotating shaft 2-7, ball 2-1 is provided with water channel 2-6, water channel 2-6 runs through ball 2-1 left and right, and ball 2-1 The upper and lower ends are respectively fixedly connected with an upper rotating shaft 2-2 and a lower rotating shaft 2-7, the ball 2-1 is rotatably connected between the two spherical shells 1-1, and the upper rotating shaft 2-2 is rotatably connected to the two upper rotating shafts Between the holes 1-7, the lower rotating shaft 2-7 is rotatably connected between the two rotating shaft holes 1-7 at the lower end, and the upper rotating shaft 2-2 is provided with a ram chute 2-3, and the ram chute 2-3 It communicates with the water channel 2-6, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com