Vertical shaft deviation monitoring method based on tilt angle sensors

The technology of an inclination sensor and a strain sensor is applied in the field of shaft deflection monitoring and vertical shaft deflection monitoring in coal mines. High precision and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

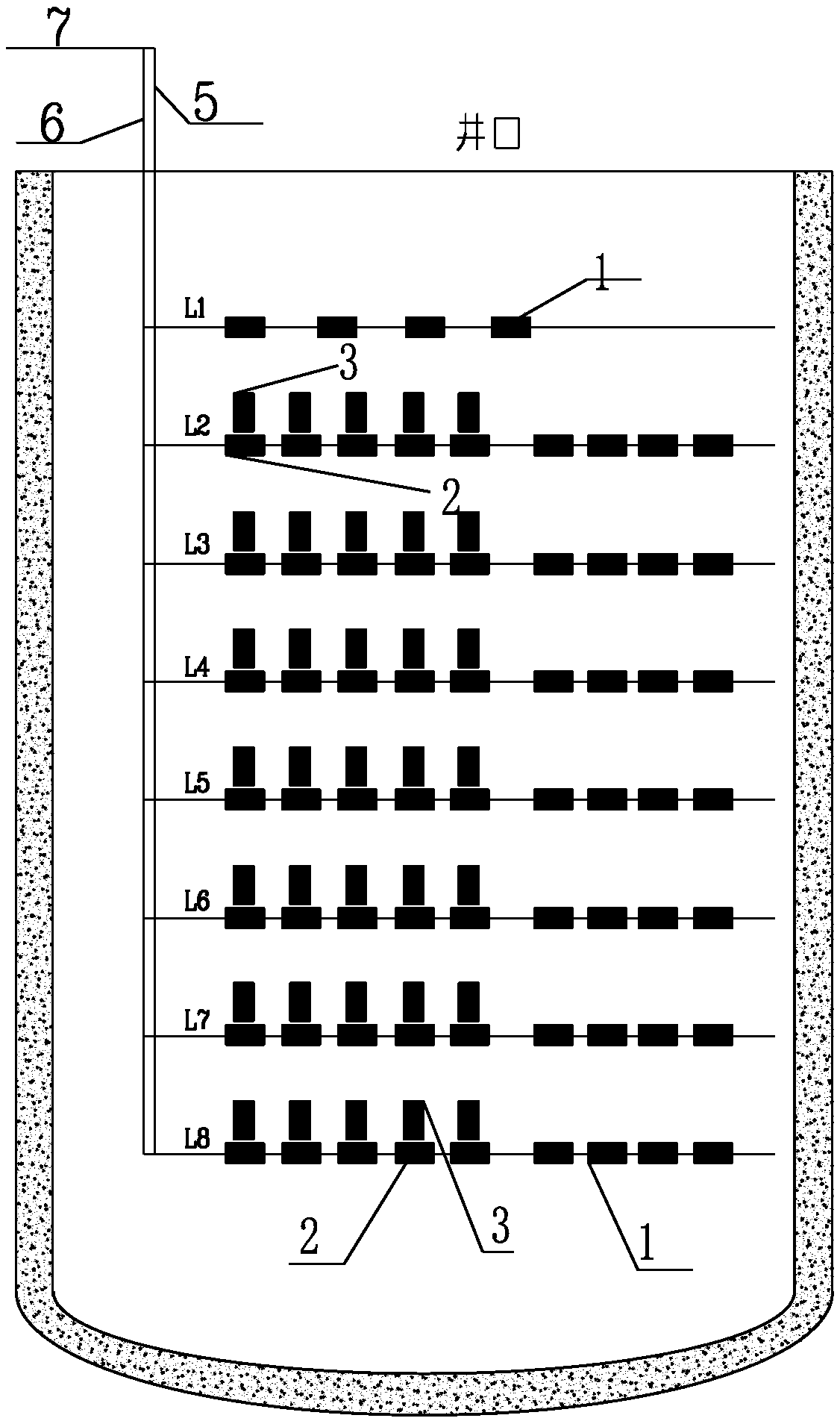

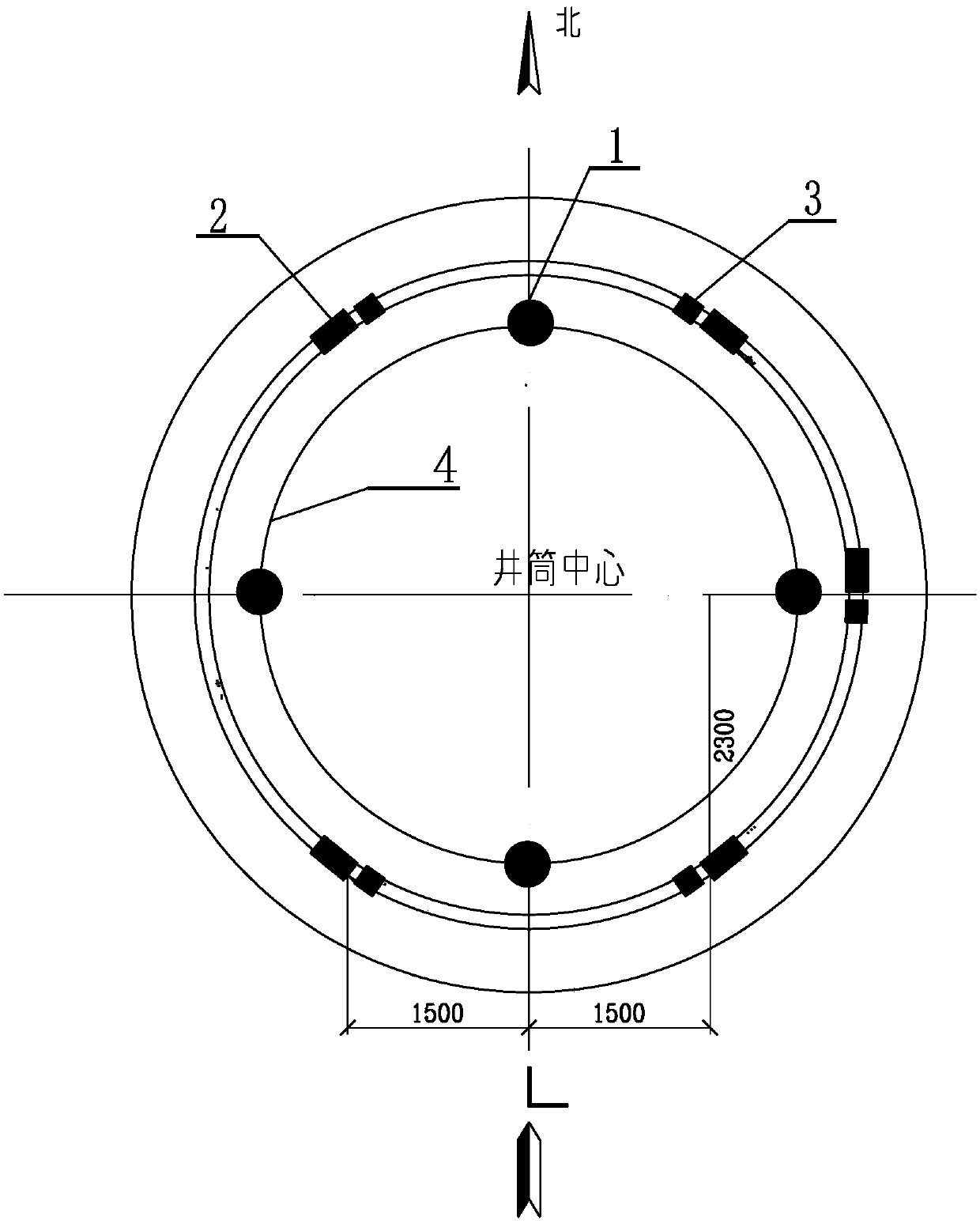

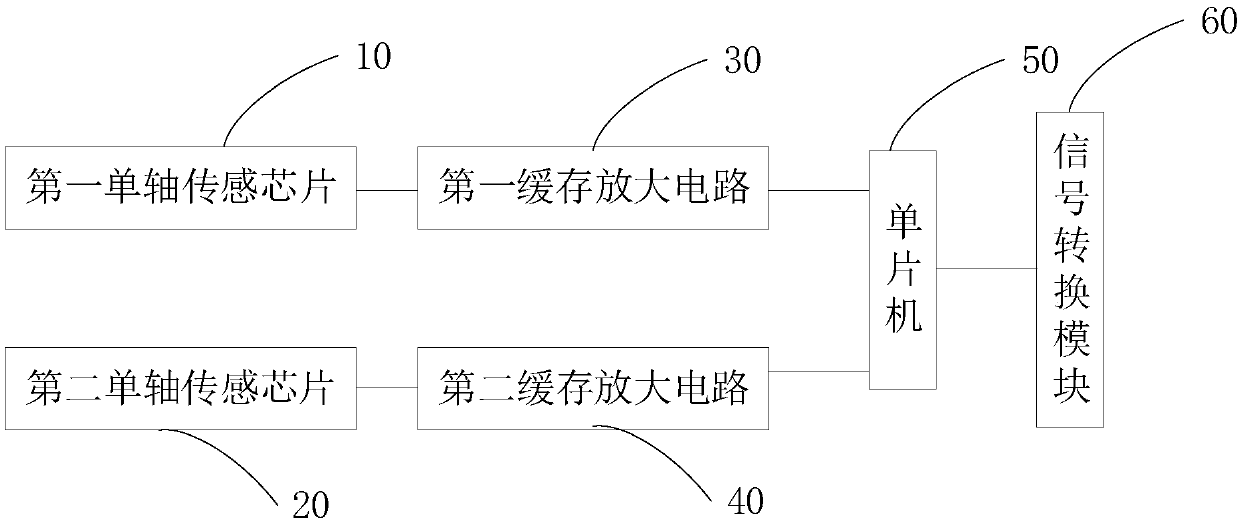

[0044] The principle of the vertical wellbore deflection monitoring method of the present invention is as follows: the side section of the wellbore structure is assumed to be a section of fixed cantilever beam. The deflection of the wellbore in the measurement section can be obtained. The more sensors are installed, the higher the measurement accuracy is. Finally, the deflection curve of the entire wellbore measurement section is fitted by the least square method. Compared with the traditional measurement method, the relative displacement change of each position of the wellbore can be directly measured by using the inclination sensor.

[0045] Based on the principle of the monitoring method, the shaft deflection monitoring method based on the inclination sensor of the present invention comprises the following steps:

[0046] (1) On the well wall, arrange 2 to 3 reference points along the bedrock position, and install an inclination sensor at each reference point for inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com