Detection method of power transformer pump type oil plug

A technology for power transformers and transformers, used in transformer/inductor cooling, transformer/inductor components, and liquid varactor machinery, etc., can solve the problems of sudden change of transformer oil flow rate, shortened transformer service life, and weakened transformer cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Concrete steps of the present invention are as follows:

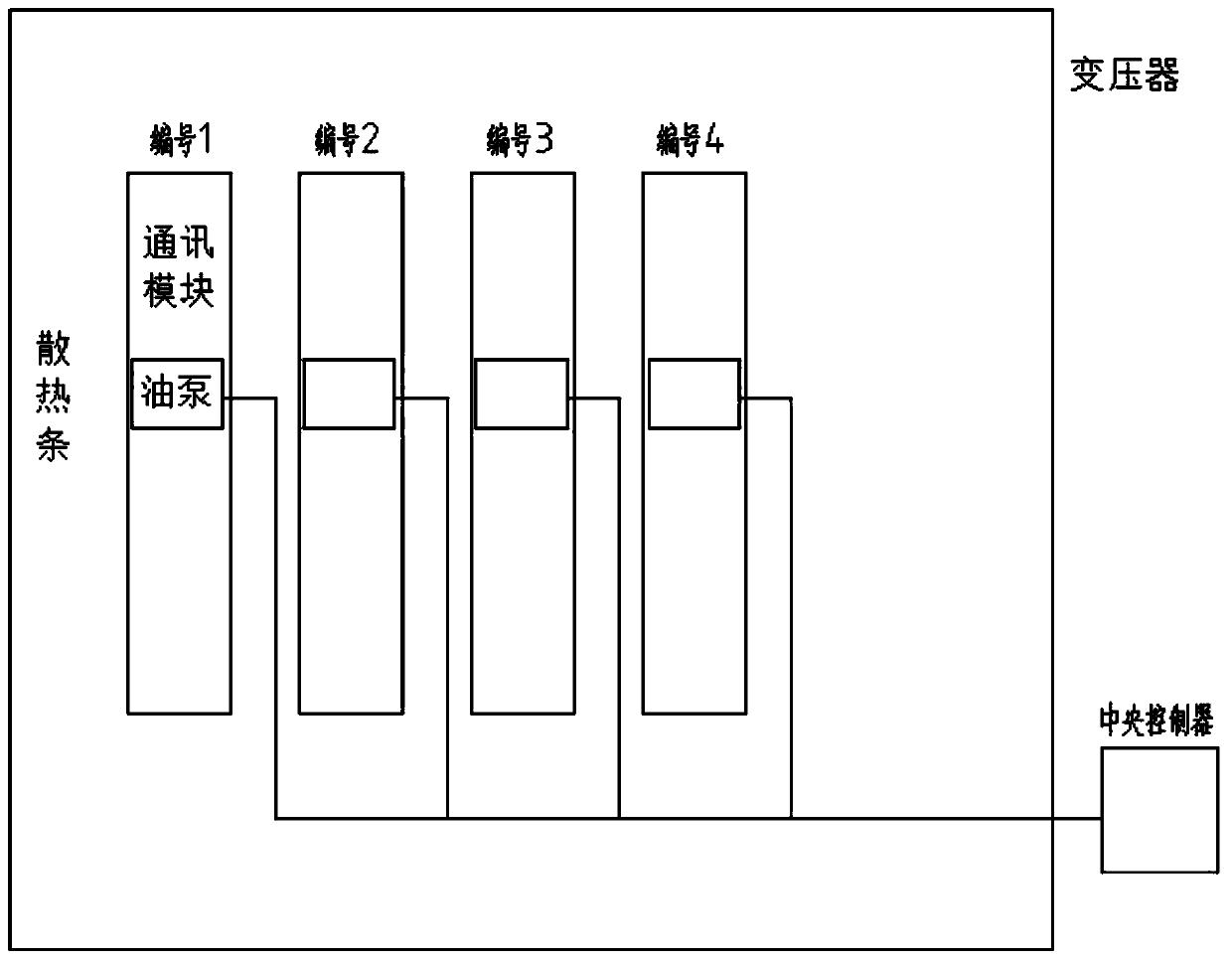

[0023] 1. If figure 1 As shown, an oil pump with oil quantity detection function is installed in the middle of each cooling strip of the transformer. The oil pump uses a unified DC power supply. , the oil pump can detect the amount of transformer oil in each time period and send it to the central controller, which is installed in the terminal box next to the transformer.

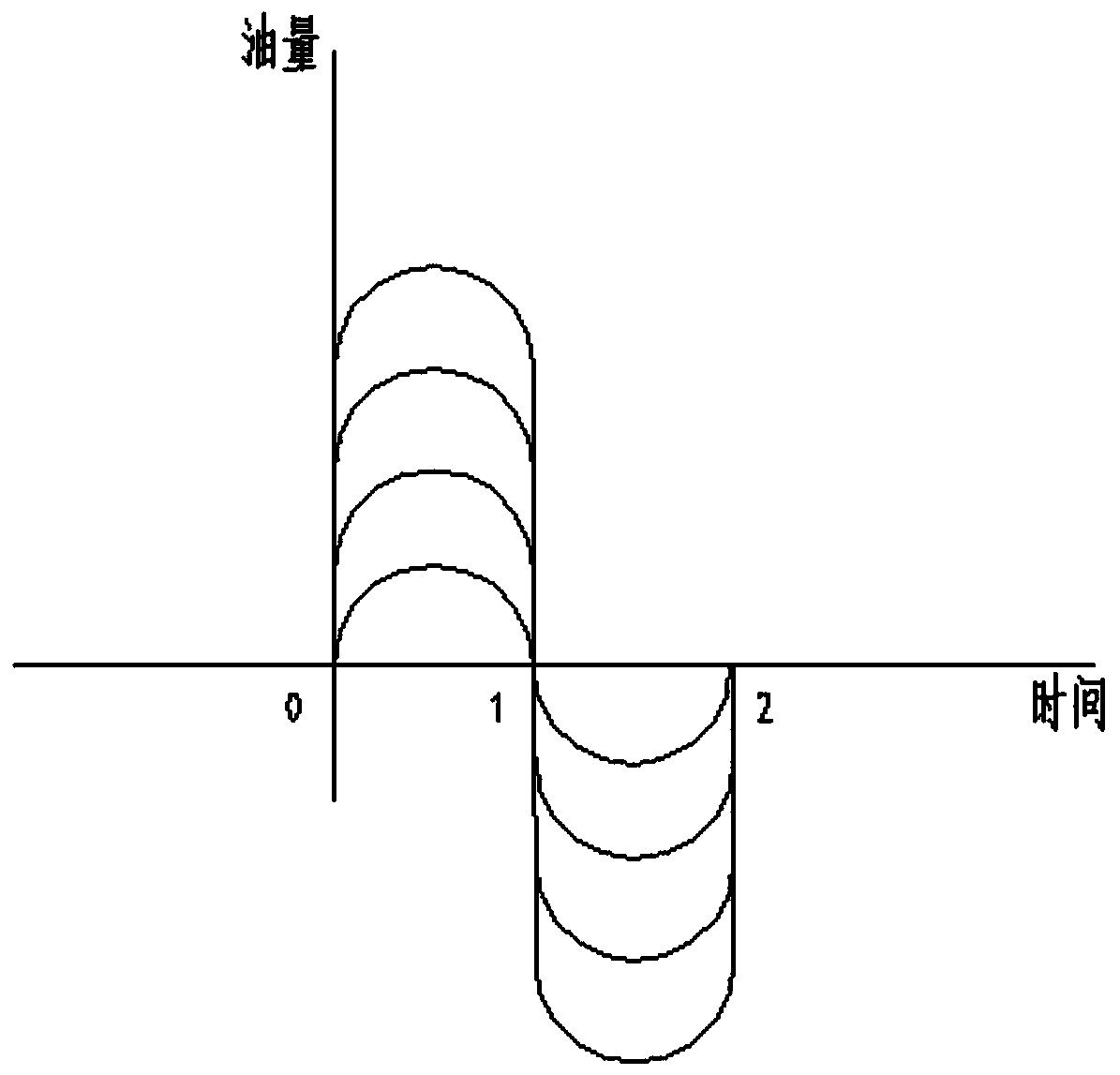

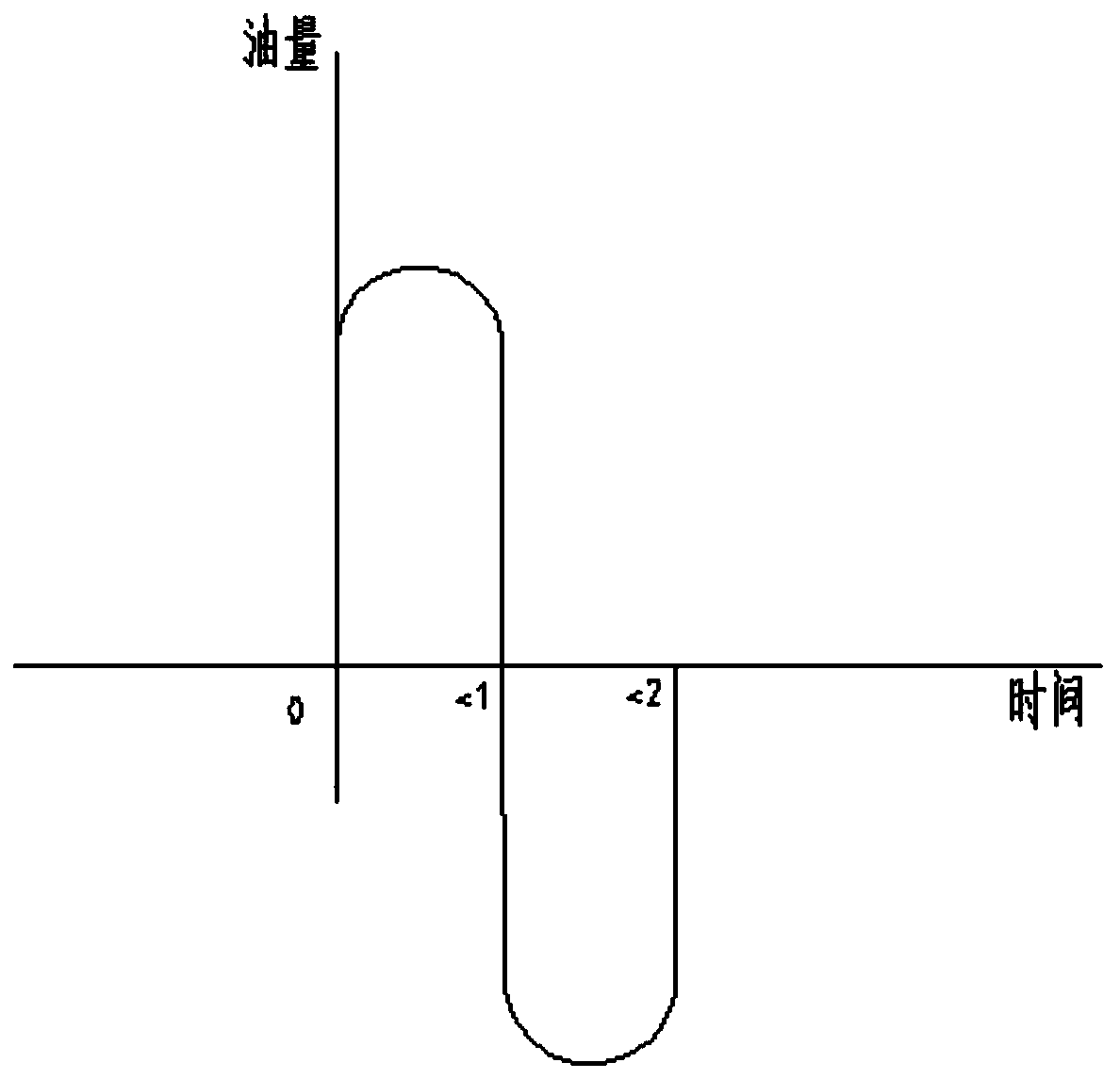

[0024] 2. After the transformer runs for the first time, the central processor starts timing, and the oil pump starts to be filled with transformer oil. Each oil pump is filled to the rated oil filling quantity successively. The oil pump that reaches the rated oil filling quantity first is controlled by the central controller to stop filling oil, press According to this rule, when all the oil pumps in the heat dissipation strips are filled to the rated oil filling volume, the oil filling process is over, and the central controller records the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com